induction brazing brass pipe to brass part

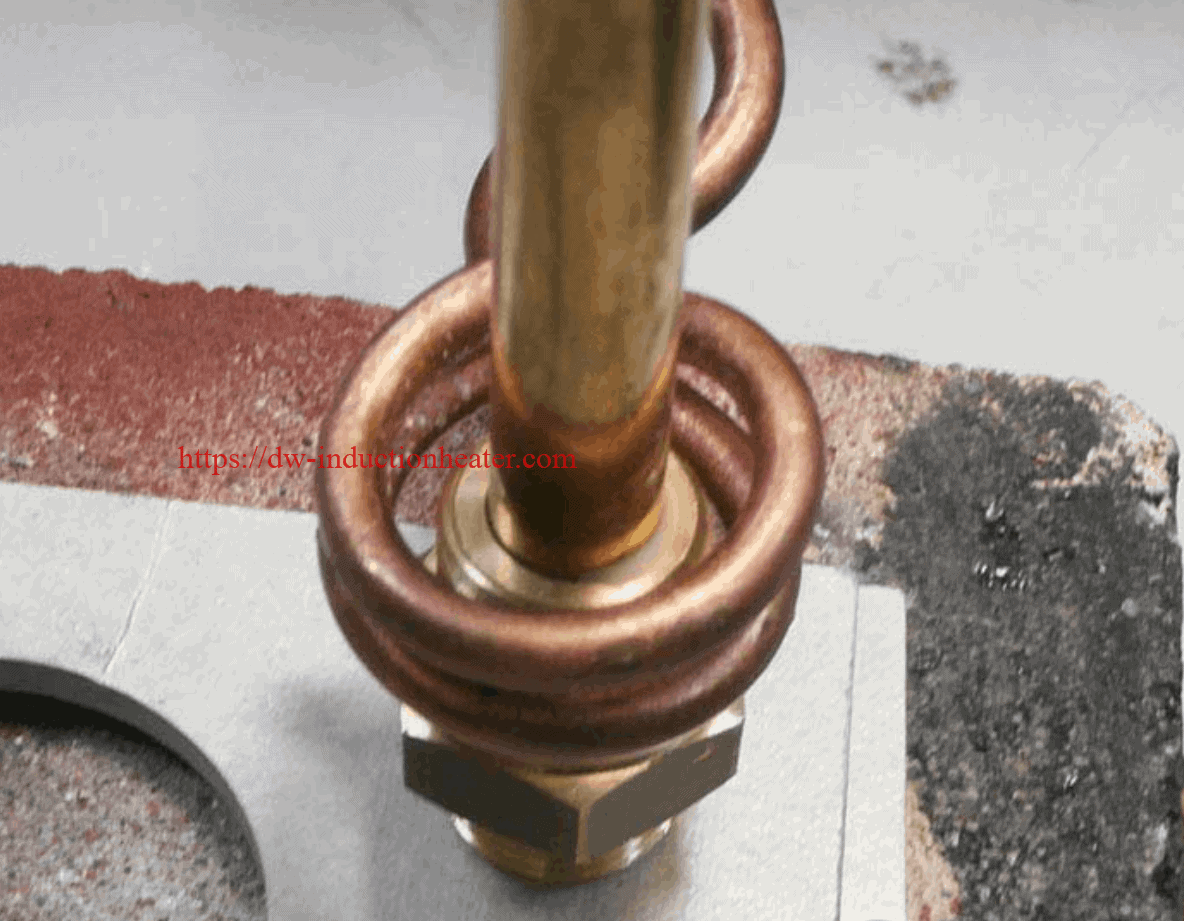

Objective High Frequency Induction Brazing brass pipe to brass part and a brass tip in under one minute using induction. Equipment DW-UHF-6KW-III handheld induction brazing machine 2 turns coil Materials • Wide brass part • Brass pipe • Silver-based brazing alloy, provided by customer Test 1 – Pipe to wide part: Key Parameters Power: 4.4 … Read more