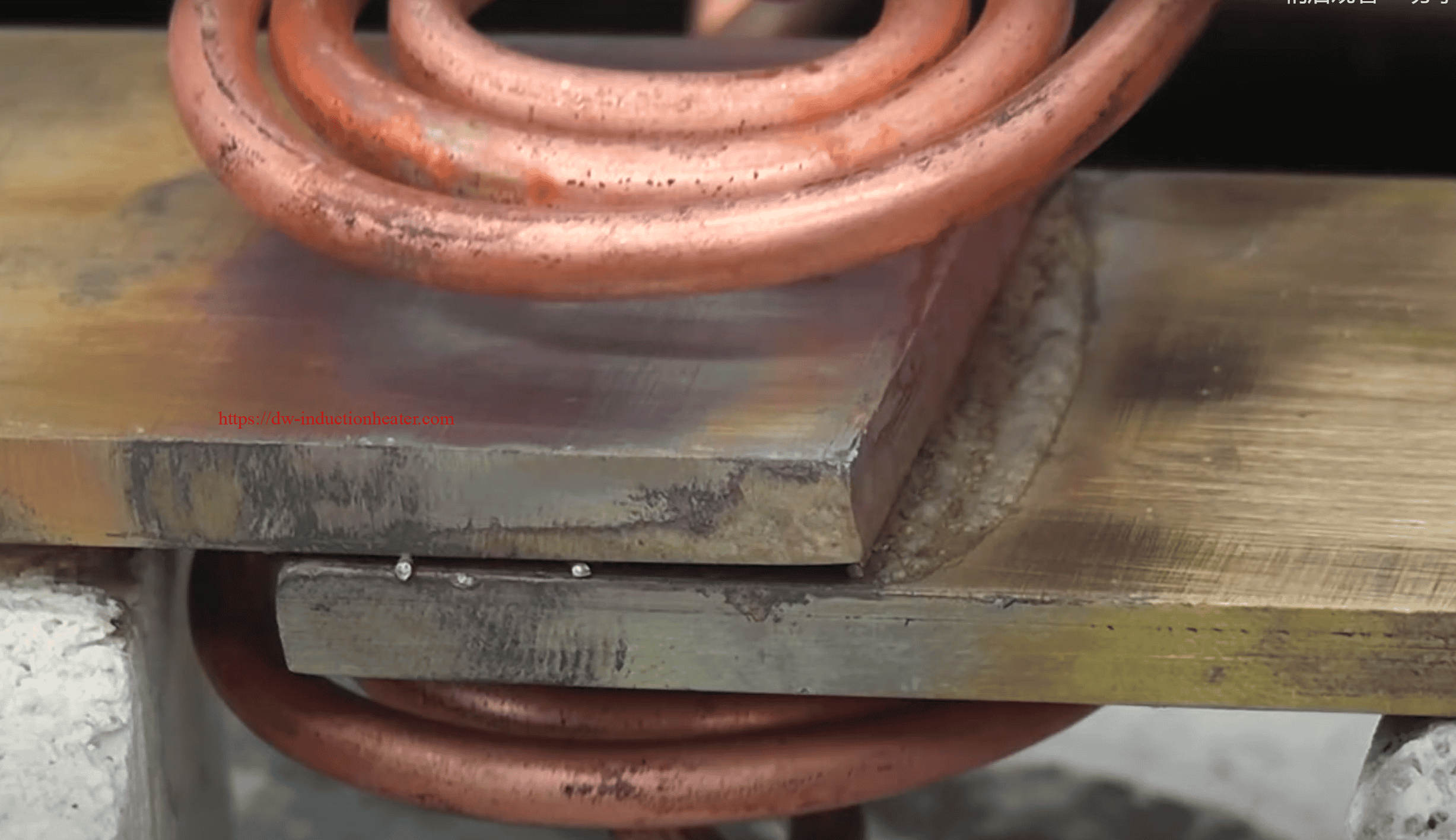

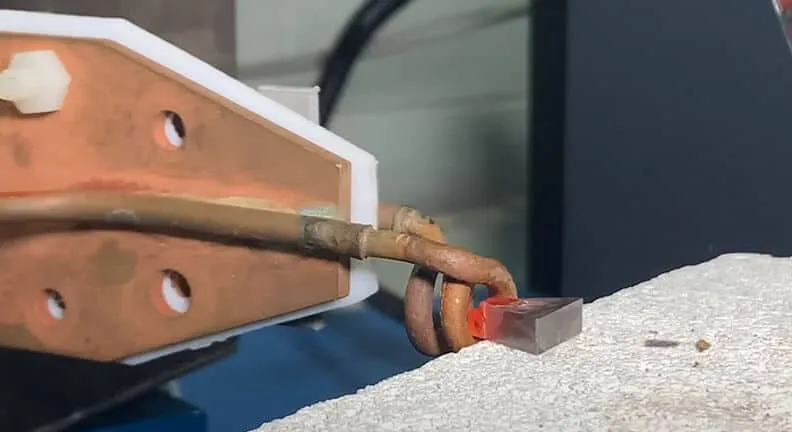

Copper and Brass Plate Joints Using Induction Heating Technology

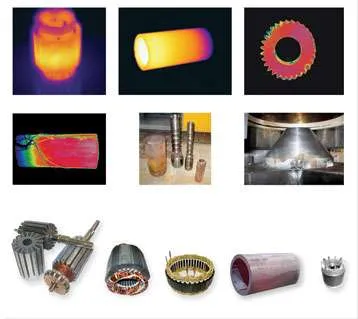

Maximizing Efficiency: Copper and Brass Plate Joints Using Induction Heating Technology In today’s rapidly evolving manufacturing landscape, the joining of copper and brass plates represents a critical process across numerous industries—from electrical engineering to plumbing systems, automotive manufacturing to renewable energy applications. While traditional joining methods have served industries well for decades, induction heating technology … Read more