Induction Brazing Carbide Tipping on Cutting Steel Tool Applications

Objective :

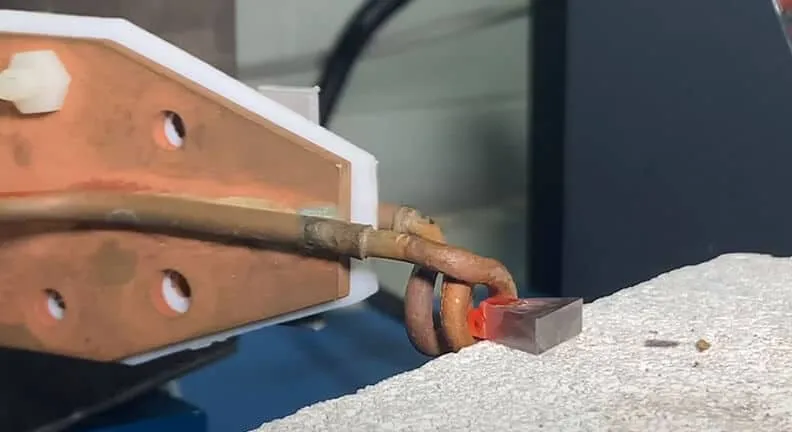

A leading manufacturer of CBN and PCD cutting tools wants to increase their productivity by focusing heat on a very small area in order to decrease heat loss and improve a carbide tipping process.

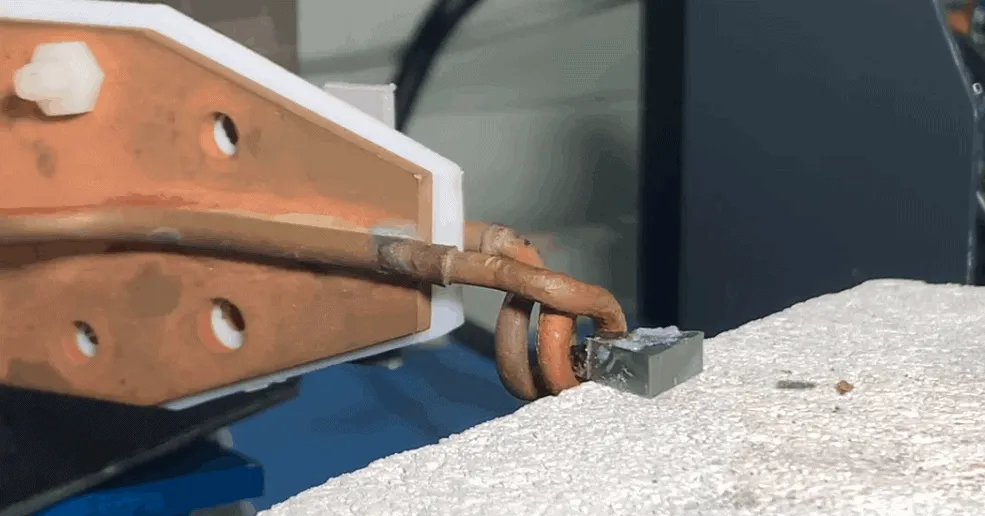

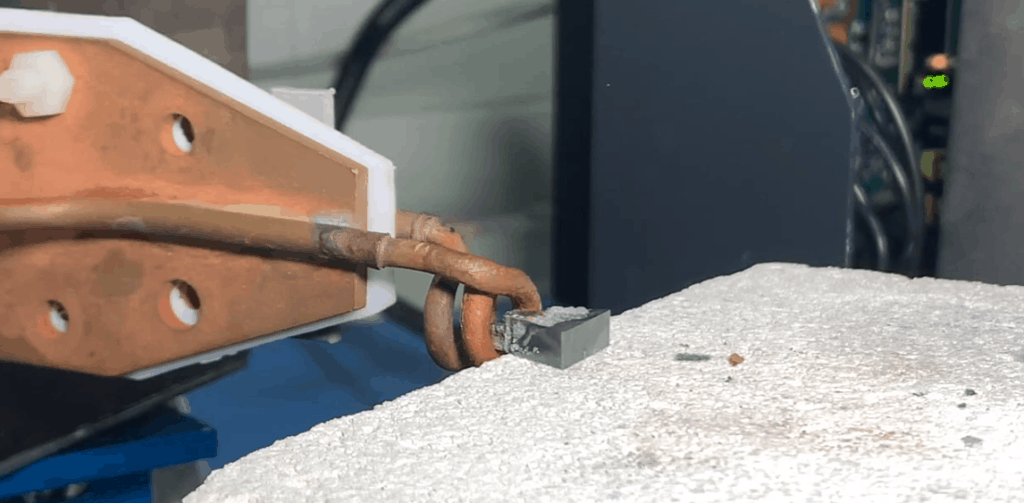

The customer provided a triangle steel body, each side ~16.5 mm (0.65 inches). The induction brazing carbide tipping must be performed on a 3 mm (0.11 inches) equilateral triangle on the edge. The heating zone of the tool steel body is 43 mm (1.69 inches) OD x 25 mm (0.98 inches) in length. DW-UHF-6kW-II induction heating system was utilized to reach 1600 °F (870 °C) and complete the process in 8 seconds. A custom-designed coil concentrated the heat in the carbide tipping zone and minimized cycle time.

Induction Brazing Equipment:

DW-UHF-6kW-II induction heating system with a customized induction brazing coil was used to fit the process requirements.

Industry: Tools & Equipment