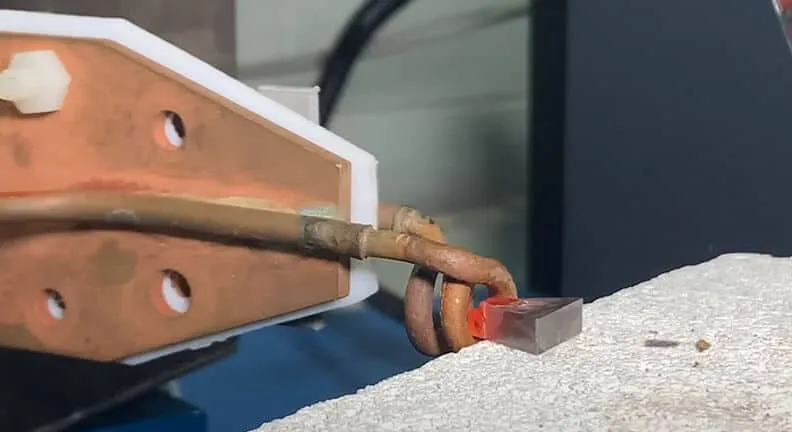

induction heating process with inert gas and vacuum technology

induction heating process with inert gas and vacuum technology Special materials or application areas require a special processing. The flux used during the conventional induction brazing process is often the cause corrosion and burns on the workpiece. Flux inclusions may also lead to an impairment of the component properties. Furthermore, due to the existing oxygen … Read more