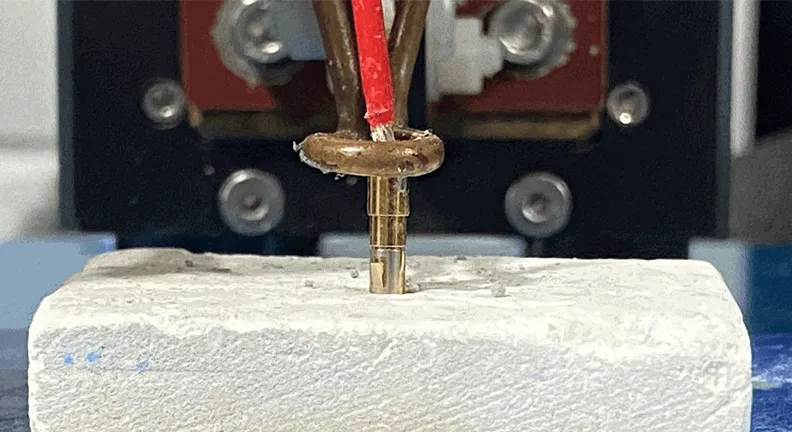

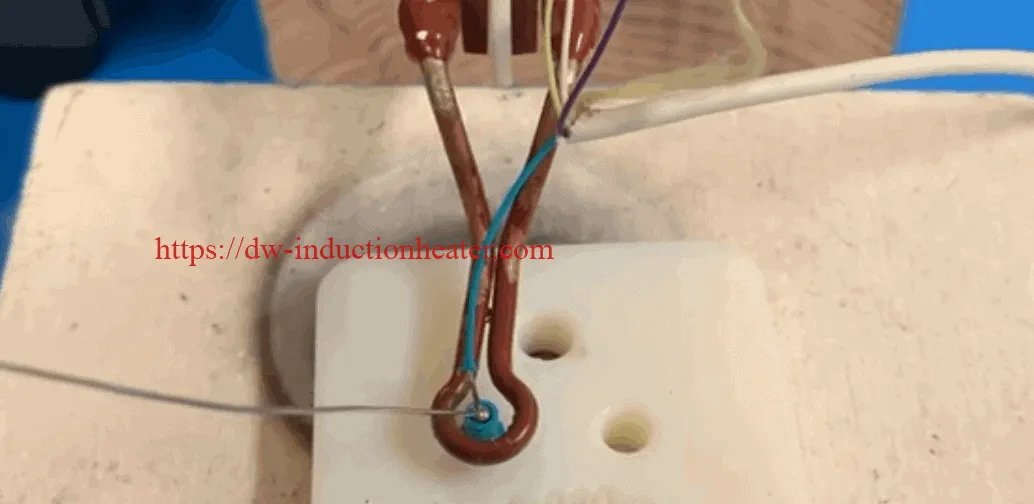

Induction Soldering Copper Cables to Copper Pins

Induction Soldering Copper Cables to Copper Pins Objective: The objective of this induction heating application is to solder cables to copper pins for harness manufacturing. The customer is a manufacturer of mission-critical test systems for the Aerospace Industry. The goal is to reduce soldering time from 10 minutes by hand to less than 1 minute … Read more