Induction Soldering Copper Tap on a Speaker Ring with IGBT Induction Heater

Objective Heat copper tab until the solder reflows.

Material Copper tab 0.25 X 0.25 inch square about 0.05 inches thick. Lead free solder material (higher melting temperature than regular solder.)

Temperature 500 ºF for 1.25 seconds

Frequency 286 kHz

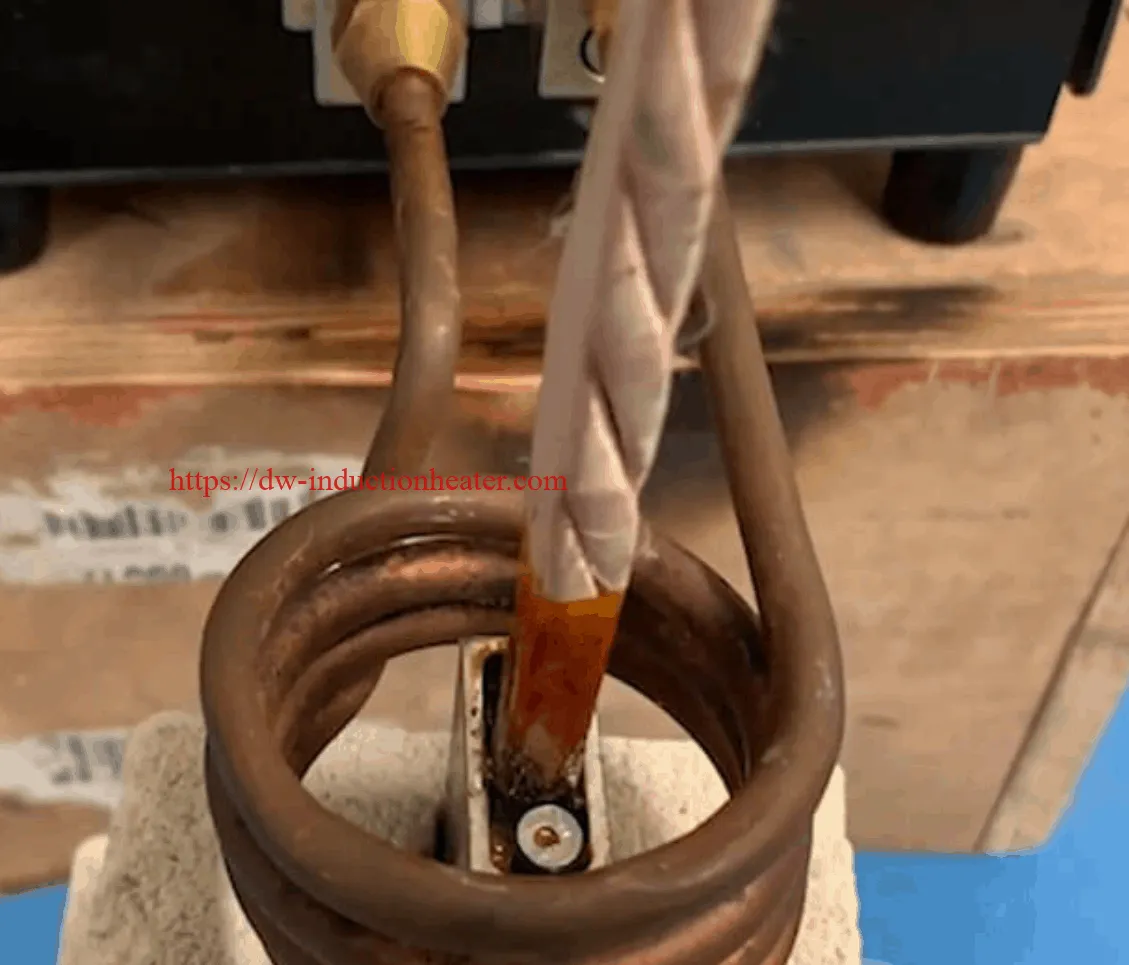

Equipment DW-UHF-4.5 kW, 150-400 kHz solid state induction heating system equipped with a remote heat station containing one 1.2 μF capacitor and a specially-designed work coil..

A multi-turn helical coil about 3/16 inch internal diameter made out of 1/16 inch diameter tubing.

Process Solder wire is fed onto speaker tab area using an automatic wire feeder. It is then heated to re-flow the solder.

Results/Benefits With an efficient coil design induction heating easily reaches the desired reflow temperature in a very short amount of time.