Induction Soldering Brass Connector In Solar Panel With IGBT Induction Heater

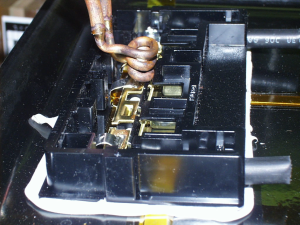

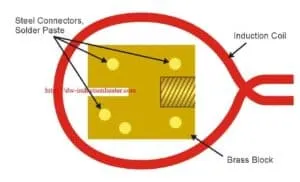

Objective Solder three brass connectors one at a time in a solar panel junction box without affecting the components in the junction box

Material Solar panel junction box, brass connectors, solder wire

Temperature 700 ºF (371 ºC)

Frequency 344 kHz

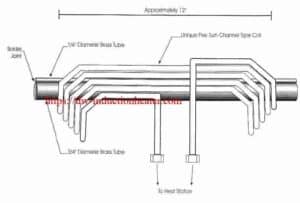

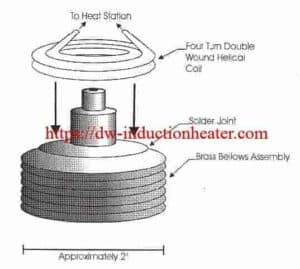

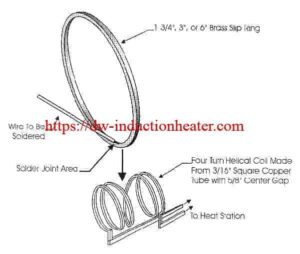

Equipment • DW-UHF-6 kW induction heating system, equipped with a remote workhead containing one 1.0 μF capacitor.

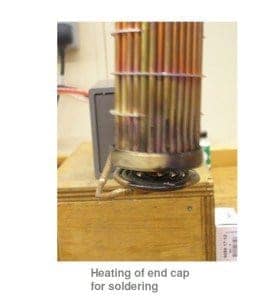

• An induction heating coil designed and developed specifically for this application.

Process A three turn oval shaped helical coil is used to heat the connectors. A piece of solder wire is placed onto the joint area and each joint is heated separately for 5 seconds to solder the connector. The total process time is 15 seconds for the three joints.

Results/Benefits Induction heating provides:

• Pinpoint accuracy deliver heating only to joint; does not affect surrounding components

• Localized heat produces neat and clean joints

• Produces high quality, repeatable results

• Even distribution of heating