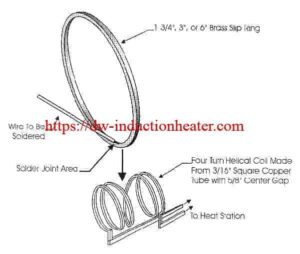

Induction Soldering Brass Rings With High Frequency IGBT Induction Heater

Objective: To heat 1 3/4″, 3″ and 6″ diameter brass slip rings and a sheathed copper wire assembly to 3600 F for soldering within three (3) to six (6) seconds. Currently production is accomplished by using a soldering iron and stick feeding rosin cored solder. This process leaves unwanted solder on the side of the slip ring where the soldering iron makes contact. The customer would like to see an increase in joint quality without sacrificing time.

Material: 303 Brass Slip Rings of 1 3/4″, 3″ and 6″ diameters. Sheathed Copper Wire Assembly.

Resin Core Solder, 37% Pb, 63% Sn.

Temperature: 3750F

Application: Through laboratory testing, the DW-UHF-20kW output solid state induction power supply along with a unique four (4) turn “ear muff” type coil produced the following results:

Times to reach 3750 F are as listed below:

– 1 3/4″ in 3 seconds

– 3″ in 3-4 seconds

– 6″ in 5 seconds

Adequate solder flow was observed producing a clean joint.

Solder preforms are recommended to speed up production.

Side loading was facilitated by the unique four (4) turn “ear muff” style coil.

Equipment: DW-UHF-20kW output solid state induction power supply including one (1) remote heat station containing one (1) 1.0 μFcapacitor, a 4-20mA input for fast ramp simulation, and a unique four (4) turn “ear muff” style coil.

Frequency: 265 kHz