Induction Soldering Brass To Copper With IGBT High Frequency Heating Equipment

Objective To heat brass and copper for soldering application on medical equipment

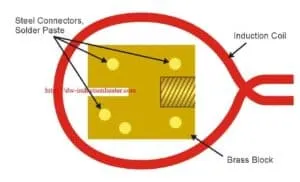

Material Brass ring, brass and copper pieces 5.11” (130mm) long, 4.3” (110mm) OD & 0.3” (7mm) at thickest point and solder rings

Temperature 392 ºF (200 ºC)

Frequency 306 kHz

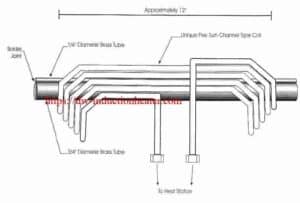

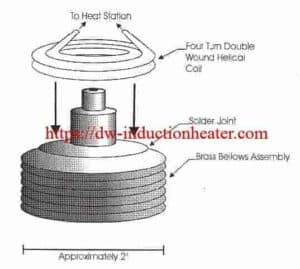

Equipment • DW-UHF-10 kW induction heating system, equipped with a remote workhead containing two 0.33μF capacitors for a total of 0.66μF

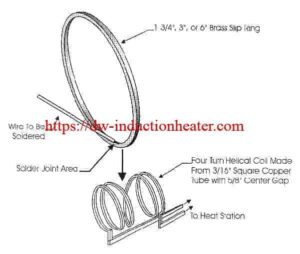

• An induction heating coil designed and developed specifically for this application.

Process This process is completed in two steps that use a 3 turn helical coil. The first process is to solder the brass ring to the copper piece which takes 85 seconds. The second step is to solder a large brass piece to the first assembly. This process takes 50 seconds for a total process time of two minutes 15 seconds.

Results/Benefits Induction heating provides:

• Hands-free heating that involves no operator skill for manufacturing

• Even distribution of heating

• Faster process time, current process takes 5 minutes

• Consistency by using solder rings