Induction Soldering Brass Tube-Pipe-Tubing With RF Soldering Heating System

Objective: Soldering two brass tubes measuring 3/4″ and 1/4″ together for use as cellular phone antennas. The lengths of tubes range from four (4) feet to twelve (12) feet, and must be soldered along the axial side. The joint is to be made using 60/40 Tin Lead Solder and Kestor Rosin paste flux.

Material: Brass Tubes measuring 3/4″ and 1/4″ 60/40 Tin Lead Solder

Kestor Rosin Flux

Temperature: 3750F

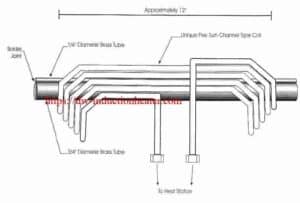

Application: Through the use of the the DW-UHF-40KW output solid state induction power supply along with a unique five (5) turn 12″ long channel coil, the following results were achieved:

3750 F was reached and the solder flowed after a heating period of 35 seconds.

A production rate of 24″ per minute was determined to be adequate.

A quality solder fillet was observed after heating and cooling

Equipment: DW-UHF-40kW output solid state induction power supply including one (1) remote heat station containing two (2) capacitors, and a unique five (5) turn channel coil made from 3/16″ copper tubing and measuring 1 1/4″ by 12″.

Frequency: 385 kHz