Induction Annealing Process

HLQ Induction is a leader in induction heating services including induction annealing.Induction annealing enables precise and reliable control of metal material properties. Induction annealing is mainly used for soft and stress-relief annealing, offering enormous advantages over conventional methods. Induction annealing enables thermal removal of impurities during bright annealing. Induction annealing is mainly used in soft annealing and stress-relief annealing and offers enormous advantages over conventional methods.Induction annealing enables the thermal elimination of impurities in the material during bright annealing.

Induction Annealing is a metal heat treatment in which a metal material is exposed to an elevated temperature for an extended time and then slowly cooled. Annealing is largely characterized by induced micro-structural changes which are ultimately responsible for altering the material’s mechanical properties. The ultimate goal of this process is to reduce the hardness of the metal and improve its ductility.

Induction Annealing is a metal heat treatment in which a metal material is exposed to an elevated temperature for an extended time and then slowly cooled. Annealing is largely characterized by induced micro-structural changes which are ultimately responsible for altering the material’s mechanical properties. The ultimate goal of this process is to reduce the hardness of the metal and improve its ductility.

Annealing services specifically refer to the process of bringing the material to its softest possible point. Our tempering process softens the metal but not to the full extent possible. The degree of temper depends on the material, the maximum temperature reached and the length of the cool down time. Process or stress relief annealing is used to negate the effects of cold work; that is, to soften and increase the ductility of a previously strain-hardened metal. Internal stresses may develop as a result of plastic deformation processes such as machining or grinding, non-uniform cooling in a welding or casting process, or a phase transformation. Distortion and warping may occur if the internal stresses are not removed. Annealing will eliminate these stresses when the part is heated to the recommended temperature, held there long enough, and slowly cooled to room temperature.

Why use annealing?

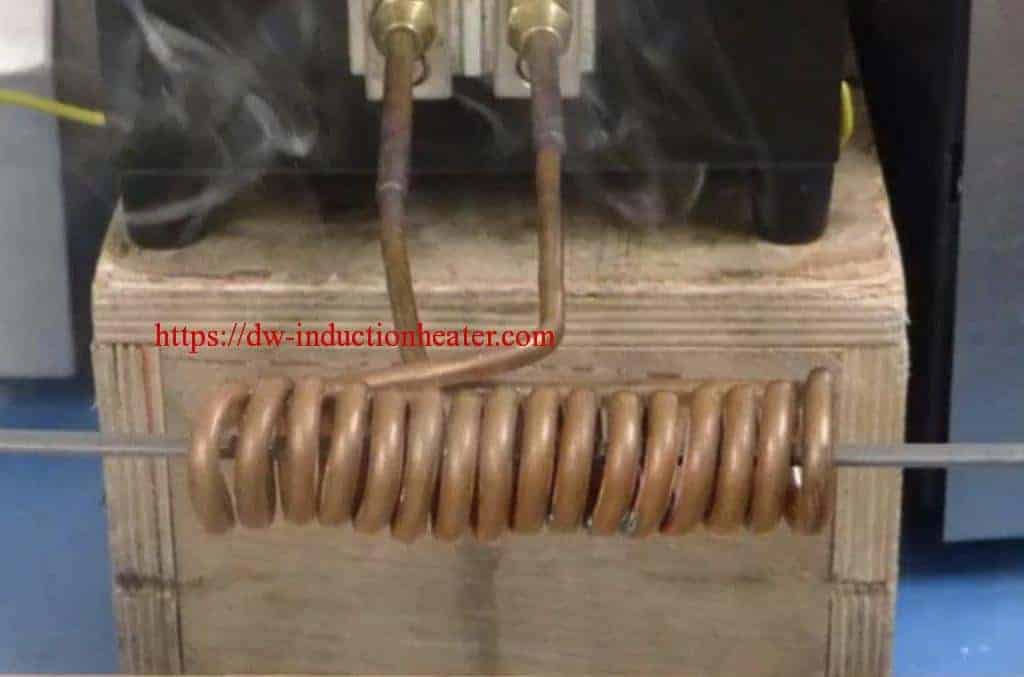

Modern induction heating provides many advantages over other heating methods and is commonly used for annealing applications. Heating through induction provides reliable, repeatable, non-contact and energy-efficient heat in a minimal amount of time. Solid state systems are capable of heating very small areas within precise production tolerances, without disturbing individual metallurgical characteristics. Induction can be used for either surface or through heating; case annealing is possible depending on time, temperature and the material’s characteristics.

Induction annealing is a generalized term referring to heating a metal to a specified temperature and then cooling at a rate that will produce a refined microstructure. Using Induction, metal can be rapidly heated to temperature at controlled an repeated cycles without contacting the metal target or heating the ambient atmosphere surrounding it. Cooling vats for ferrous metals are usually in open air resulting in the formation of pearlite. Non-ferrous metals, such a copper or brass, can be subjected to rapid cooling by quenching in water. The results “soften” the material and make it more easily formed to a required shape.

Induction Annealing is commonly used in wire processing, precision tool forming, and tube forming applications. Typical materials for induction annealing include aluminum, carbon Steel, and carbide. Some of the benefits of Induction annealing are: power on demand; rapid heat cycles; elimination of continuous power to large heating area (i.e. oven); cost savings due to reduced power usage; direct heating of the metal and not the ambient air as in convection processes; safer process than open flame methods; improved process control for even heating and uniform heating to a given temperature that is not dependent on operator skill.

Why choose HLQ induction for induction annealing?

We are industry leaders in induction heating with offices in China.

Induction annealing is a kind of heat treatment by induction heater, heat a metal to a specified temperature and then cooling at a rate that will produce a refined microstructure. Using Induction heating, metal can be rapidly heated to temperature at controlled an repeated cycles without contacting the metal target, material are usually cooled in open air. The results “soften” the material and make it more easily formed to a required shape.

The benefit of annealing with induction heating:

1. High production rates

2. Less heating area and non continually power need (i.e. oven)

3. Save cost due to increased production and reduced labor costs

4. Easy to control heating time and temperature

Because we specialize in induction heating, our customers benefit from integrated induction annealing solutions in many industries.

Our customers avoid excessive inventory and part handling through the use of induction annealing, which results in minimum waste and improved results at a low cost.We have top-notch technology, equipment, and process yielding units that meet the highest quality standards.