Induction Nanoparticle Heating: A Comprehensive Guide to Revolutionizing Cancer Treatment and Beyond

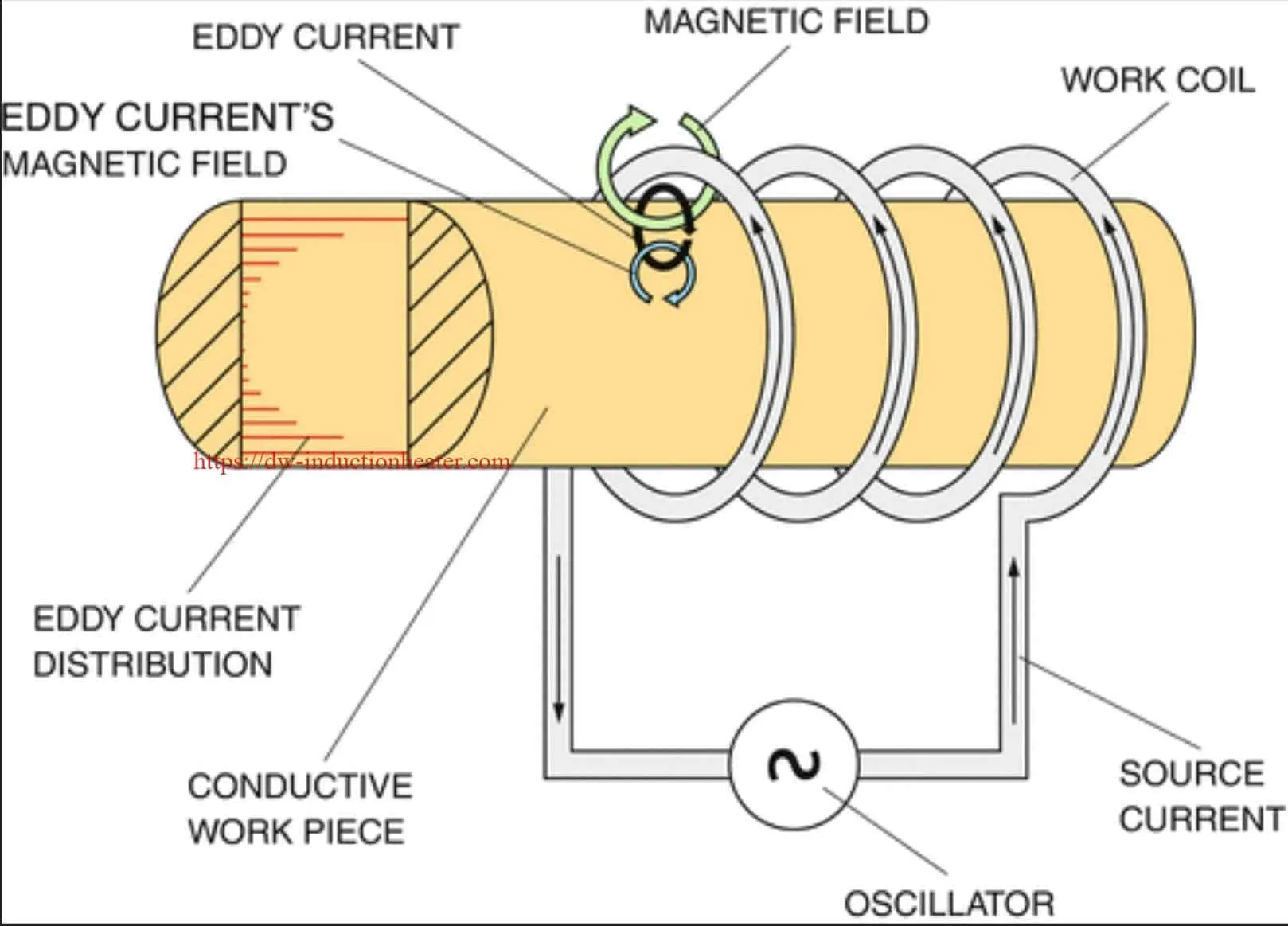

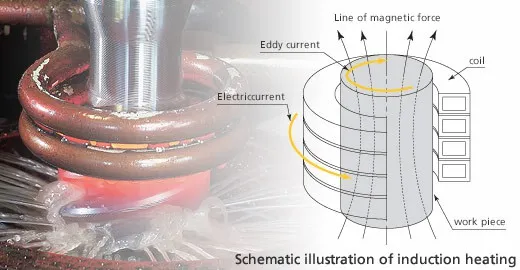

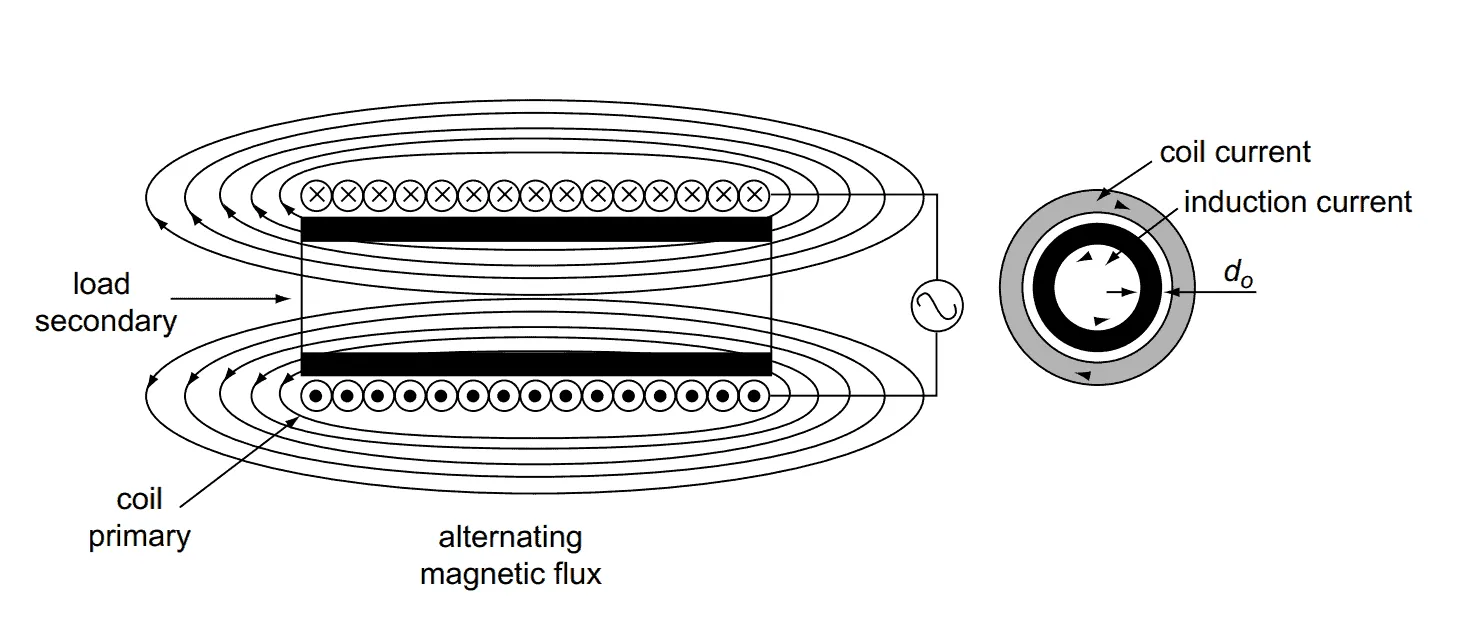

Induction Nanoparticle Heating: A Comprehensive Guide to Revolutionizing Cancer Treatment and Beyond Table of Contents Induction Nanoparticle Heating: A Comprehensive Guide to Revolutionizing Cancer Treatment and Beyond 1 Table of Contents. 1 Introduction to Induction Nanoparticle Heating. 1 The Science Behind Induction Heating of Nanoparticles. 1 Types of Nanoparticles Used in Induction Heating. 2 Applications … Read more