Full Solid IGBT Induction Furnace | Induction Melting Furnace for melting copper, brass, iron steel,gold and other metals.

Applications:

Full Solid IGBT Medium frequency induction melting furnaces are mainly used for the melting of steel, stainless steel, copper, brass, silver, gold, and aluminum materials, etc. Melting capacity can be from 3KG to 600KG.

Structure of the M. F.induction melting furnace:

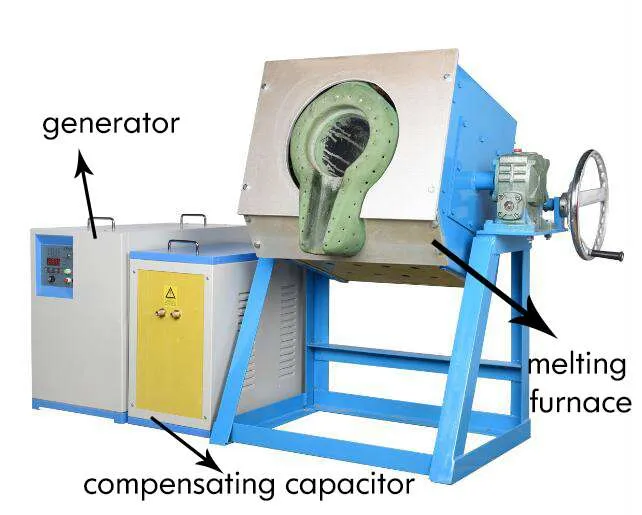

The furnace set includes medium frequency generator, compensating capacitor and melting furnace, infrared temperature sensor and temperature controller can also be included if ordered.

Three types of induction melting furnaces can be ed according to the way of pouring out, They are tilting furnace, push-up furnace and stationary furnace.

According to the method of tilting, tilting furnace is divided into three kinds: manual tilting furnace, electrical tilting furnace and hydraulic tilting furnace.

| Model | DW-MF-15 | DW-MF-25 | DW-MF-35 | DW-MF-45 | DW-MF-70 | DW-MF-90 | DW-MF-110 | DW-MF-160 | ||

| Max Input power | 15KW | 25KW | 35KW | 45KW | 70KW | 90KW | 110KW | 160KW | ||

| Max Input current | 23A | 36A | 51A | 68A | 105A | 135A | 170A | 240A | ||

| Output current | 3-22A | 5-45A | 10-70A | 15-95A | 20-130A | 25-170A | 30-200A | 30-320A | ||

| Output voltage | 70-550A | |||||||||

| Input voltage | 3phase 380V 50 or 60HZ or according customer’s requirement. | |||||||||

| Frequency | 1KHZ – 20KHZ | |||||||||

| Duty cycle | 100% 24hours continuous working | |||||||||

| Generator net weight | 26 | 28 | 35 | 47 | 75 | 82 | 95 | 125 | ||

| Generator size LxWx H cm | 47x27x45 | 52x27x45 | 65x35x55 | 75x40x87 | 82x50x87 | |||||

| Timer | Heating time: 0.1-99.9seconds retaining time: 0.1-99.9seconds | |||||||||

| Front panel | LCD, display frequency, power, time etc. | |||||||||

| Whole systems water flow | ≥0.2Mpa ≥6L/Min | ≥0.3Mpa ≥10L/Min | ≥0.3Mpa ≥20L/Min | ≥0.3Mpa ≥30L/Min | ||||||

| Power supply water flow | ≥0.2Mpa ≥3L/Min | ≥0.2Mpa ≥4L/Min | ≥0.2Mpa ≥6L/Min | ≥0.2Mpa ≥15L/Min | ||||||

| Water way | 1 water inlet, 1 water outlet | 1 water inlet, 3 water outlet | ||||||||

| Max water temp. | ≤40℃ | |||||||||

| Auxiliary Function | 1.model DW-MF-XXA has timer function, heating time and retaining time can be preset and controlled independently from 0.1-99.9second. 2.model DW-MF-XXB is used together with transformer. | |||||||||

Specifications

Specifications- Main models and melting abilities of induction melting furnace

- The table below lists the main models and recommended maximum melting abilities. First time About 50 to 60 minutes are needed to finish one melting process at cool status of the induction furnace, at hot status of the induction furnace, about 30-40 minutes are needed.

| Model | Max input power | Maximum melting capacity | ||

| Iron, steel, stainless steel | Brass, copper, silver, gold, etc. | Aluminum | ||

| DW-MF-15 induction melting furnace | 15KW | 3KG | 10KG | 3KG |

| DW-MF-25 induction melting furnace | 25KW | 5KG | 20KG | 5KG |

| DW-MF-35 induction melting furnace | 35KW | 10KG | 30KG | 10KG |

| DW-MF-45 induction melting furnace | 45KW | 18KG | 50KG | 18KG |

| DW-MF-70 induction melting furnace | 70KW | 25KG | 100KG | 25KG |

| DW-MF-90 induction melting furnace | 90KW | 40KG | 120KG | 40KG |

| DW-MF-110 induction melting furnace | 110KW | 50KG | 150KG | 50KG |

| DW-MF-160 induction melting furnace | 160KW | 100KG | 250KG | 100KG |

- Description

Medium frequency induction melting furnace are mainly used for the melting of gold, silver, platinum, copper, brass, bronze, zinc, steel, stainless steel, iron, aluminum and alloy materials, etc. melting capacity can be from 0.1-250kg

The composing of the Medium frequency induction melting furnace

Medium Frequency induction heating generator.

Compensating capacitor.

Melting furnace.

Infrared temperature sensor, temperature controller and water cooling system can also optional.

Three types of induction melting furnaces can be selected according to the way of pouring out, they are tilting furnace, push-up furnace and stationary furnace.

According to the method of tilting, tilting furnace is divided into three kinds: Manual tilting furnace, Electrical tilting furnace and Hydraulic tilting furnace.

Main Features of DW-MF induction melting furnace

Medium frequency induction melting furnace can be used for the melting of steel, stainless steel, iron, brass, copper, aluminum, gold, silver, platinum , zinc, metal alloys and so on.

Because of the stirring effect which caused by the magnetic force, the melting pool can be stirred during the melting course to ease the floating of the flux and oxides to produce high quality casting parts.

Wide frequency range from 1KHZ to 20KHZ, working frequency can be designed by changing the coil and compensating capacitor according to the melting material, quantity, stirring effect desire, working noise, melting efficiency and other factors.

Compared with SCR medium frequency induction furnace, it can save energy at least 20% and up.

Small and light weight, a lot of modes can be selected to melt different amount of metals. Not only it is suitable for the factory, but also suitable for the college and researching companies to use.

24hours non-stop melting ability.

It’s easy to change melting furnace for different capacity, different material, different way of pouring out, to suitable for all kinds of requirements.