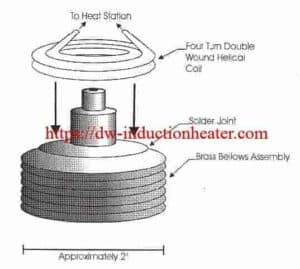

Induction Soldering Brass Assembly With High Frequency Soldering Units

Objective: To heat a brass bellows and end cap assembly to 4500F for soldering within 20 seconds. Presently, a soldering iron is used to produce the joint between the bellows and cap. The customer requests a quality solder joint with minimal heating of the bellows to prevent annealing and performance losses. Solder preforms, in the form of flat washers, are to be used to complete this application.

Material: Brass Bellows measuring 2″ in diameter Solder Preforms

Cadmium Free Flux

Temperature: 4500F

Application: The DW-UHF-20kW output solid state induction power supply along with a unique three (3) turn double wound helical coil was utilized to achieve the following results:

4500F was reached and solder flow completed in 6.3 seconds.

A quality repeatable solder joint was observed.

Equipment: DW-UHF-20kW output solid state induction power supply including one (1) remote heat station containing one (1) 1.2 μF capacitor, and a unique three (3) turn double wound helical coil with an inside diameter of 0.4″.

Frequency: 307 kHz