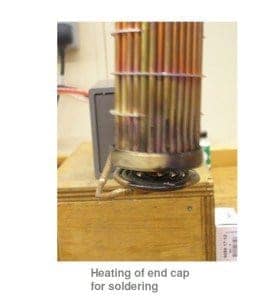

Induction Soldering Brass Heating Exchanger Of a Series Copper Pipe

Objective To solder a brass end cap to a series of copper tubes

Material Preassembled heat exchanger with copper tubes and 2 brass end caps 2.36” (60mm) OD, 0.08” to 0.12” (2 to 3mm) thick at both ends, liquid solder

Temperature 302ºF (150ºC)

482ºF (250ºC)

Frequency 237kHz

Equipment • DW-UHF-20kW induction heating system, equipped with a remote workhead containing one 1.0μF capacitor

• An induction heating coil designed and developed specifically for this application.

Process A dual four turn pancake coil is used to solder 2 brass caps per cycle. Liquid solder is squirted onto the end cap and is heated for 18 seconds at 302ºF (150ºC) to burn off the flux. Then the

heat is increased to 482ºF (250ºC) for 15 seconds to solder the parts.

Results

Induction heating provides:

• Even distribution of heating

• Compared to hot plate, induction heating is able to heat two parts in 30 seconds vs. one part in 60 seconds

• Increased production

• No discoloration with the slow heating process