Induction Soldering Wire of Co-axial With High Frequency Heating Units

Objective To solder center-conductor and shielding braid of wire assemblies to 500 (250) °F(°C).

Material • Customer-supplied assemblies

• Temperature indicating paint

• Flux-cored solder wire

Temperature 500 (250) °F (°C)

Frequency 272 kHz

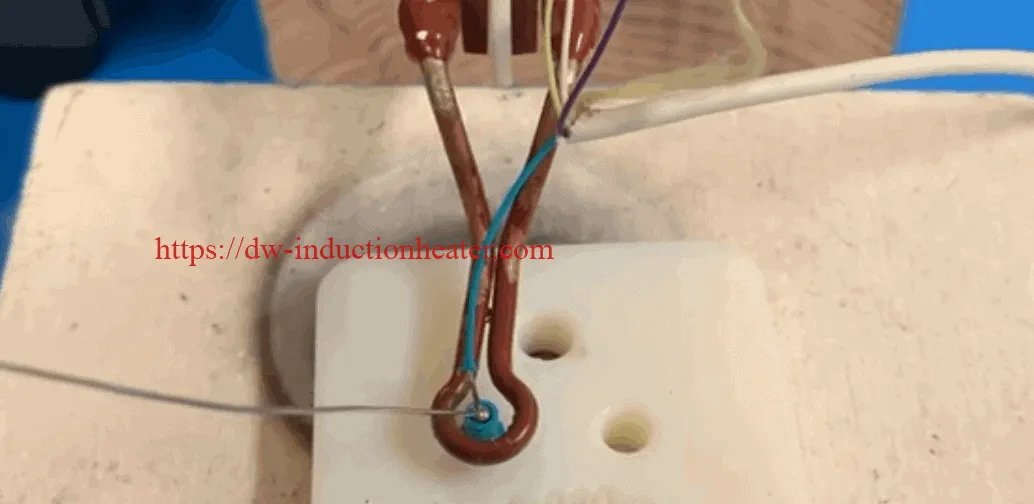

Equipment DW-UHF-4.5kW induction heating system, equipped with a remote heat station containing two 0.33 μF capacitors. An induction heating coil designed and developed specifically for this application.

Process A multi-turn helical coil is used and temperature-indicating paint is applied to the joint area. The wire assembly is placed over the induction heating coil, and RF power is applied. The time-to-temperature and the heating pattern on the part are established. The next wire assembly is placed on the coil, the assembly is heated and solder wire is fed into the joint. The assembly heats well and reaches 500 °F in 10 seconds.

Results/Benefits • elimination of a crimp process

• more reliable connections are made

• faster process times