Brazing Carbide to Steel Part With Induction Heating

Objective

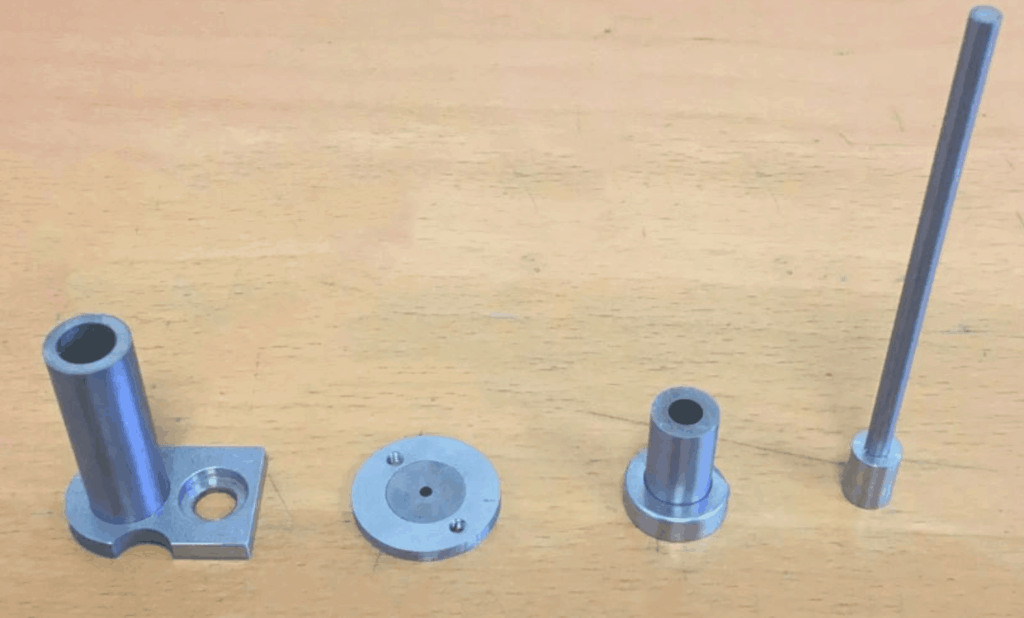

Brazing carbide to steel part

Equipment

DW-UHF-6kw Induction Heating Power Supply

ultra high frequency custom coil

Key Parameters

Power: 1.88 kW

Temperature: Approximately 1500°F (815°C)

Time: 14 sec

Materials

Coil-

2 helical turns (20 mm ID)

1 planar turn (40 mm OD, 13 mm Height)

Carbide-

13 mm OD, 3 mm wall thickness

Steel piece–

20 mm OD, 13 mm ID

Induction Brazing Process:

- To demonstrate elimination of “hand feeding” the alloy, we formed the alloy into a ring to tightly fit over the center post tube. This method provides a uniform amount for each cycle, resulting in uniform joints and wetting.

- The custom made coil was then placed over the steel piece, where is was set for 14 seconds to heat the alloy.

- The alloy was heated at approximately 1500°F (815)°C

- The whole piece is left alone and cooled with ambient air