Induction Brazing Technology

Induction Brazing Principle|Theory

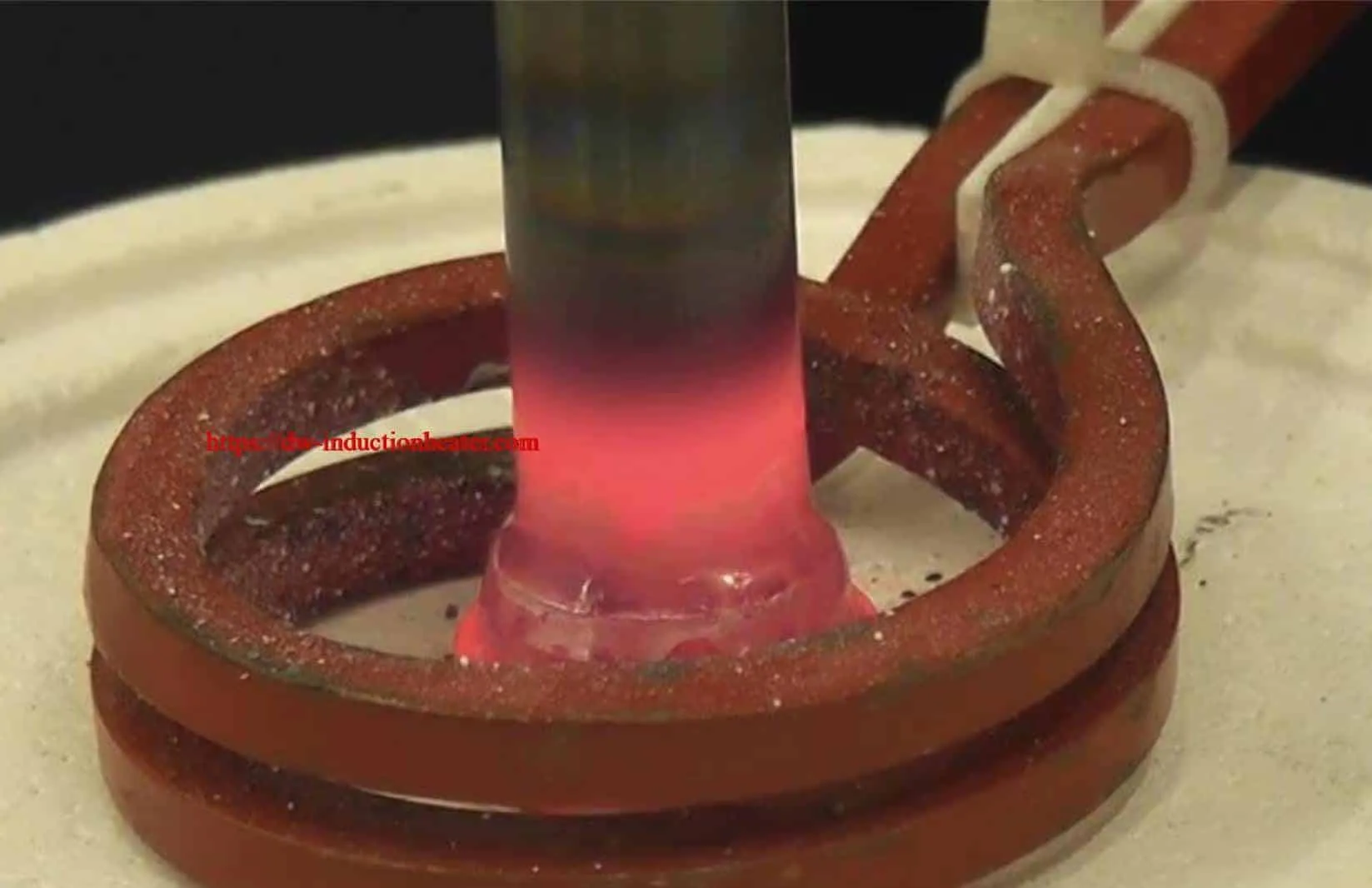

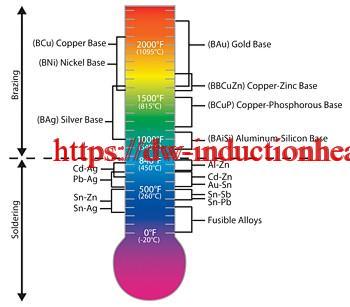

Brazing and soldering are processes of joining similar or dissimilar materials using a compatible a filler material. Filler metals include lead, tin, copper, silver, nickel and their alloys. Only the alloy melts and solidifies during these processes to join the work piece base materials. The filler metal is pulled into the joint by capillary action. Soldering processes are conducted below 840°F (450°C) while brazing applications are conducted at temperatures above 840°F (450°C) up to 2100°F (1150°C).

The success of these processes depends upon the assembly’s design, clearance between the surfaces to be joined, cleanliness, process control and the correct selection of equipment needed to perform a repeatable process.

Cleanliness is ordinarily obtained by introducing a flux which covers and dissolves dirt or oxides displacing them from the braze joint.

Many operations are now conducted in a controlled atmosphere with a blanket of inert gas or combination of inert / active gasses to shield the operation and eliminate the need for a flux. These methods have been proven on a wide variety of material and part configurations replacing or complimenting atmosphere furnace technology with a just in time – single piece flow process.

Brazing Filler Materials

Brazing filler metals can come in a variety of forms, shapes, sizes and alloys depending on their intended use. Ribbon, preformed rings, paste, wire and preformed washers are just a few of the shapes and forms alloys that can be found.

The decision to use a particular alloy and/or shape is largely dependent on the parent materials to be joined, placement during processing and the service environment for which the final product is intended.

Clearance Affects Strength

Clearance between the faying surfaces to be joined determines the amount of braze alloy, capillary action / penetration of the alloy and subsequently the strength of the finished joint. The best fit up condition for conventional silver brazing applications are 0.002 inches (0.050 mm) to 0.005 inches (0.127 mm) total clearance. Aluminum is typically 0.004 inches (0.102 mm) to 0.006 inches (0.153 mm). Larger clearances up to 0.015 inches (0.380 mm) usually lack sufficient capillary action for a successful braze.

Brazing with copper (above 1650°F / 900°C) requires the joint tolerance kept to an absolute minimum and in some cases press fit at ambient temperatures to assure minimum joint tolerances while at the brazing temperature.

Induction Heating Theory

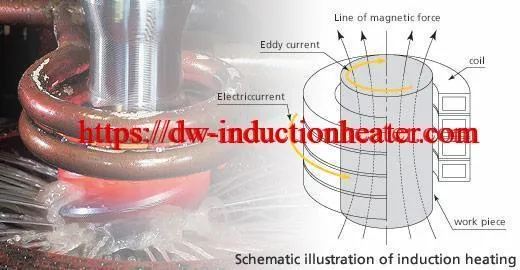

Induction systems provide a convenient and precise way to quickly and efficiently heat a selected area of an assembly. Consideration must be given to the selection of power supply operating frequency, power density (kilowatt applied per square inch), heating time, and induction coil design to provide the required depth of heating in a specific braze joint.

Induction heating is non-contact heating by means of transformer theory. The power supply is an AC source to the induction coil that becomes the primary windings of the transformer while the part to be heated is the transformer’s secondary. The work piece heats by the base materials’ inherent electrical resistivity to the induced current flowing in the assembly.

Current passing through an electrical conductor (the workpiece) results in heating as current meets resistance to its flow. These losses are low in current flowing through aluminum, copper and their alloys. These non-ferrous materials require additional power to heat than their carbon steel counterpart.

The alternating current tends to flow on the surface. The relationship between the frequency of the alternating current and the depth it penetrates the part is known as the reference depth of heating. Part diameter, material type and wall thickness can have an effect on heating efficiency based on the reference depth.