Unlocking the Heat:10 FAQs About Induction Hardening

- What exactly is induction hardening?

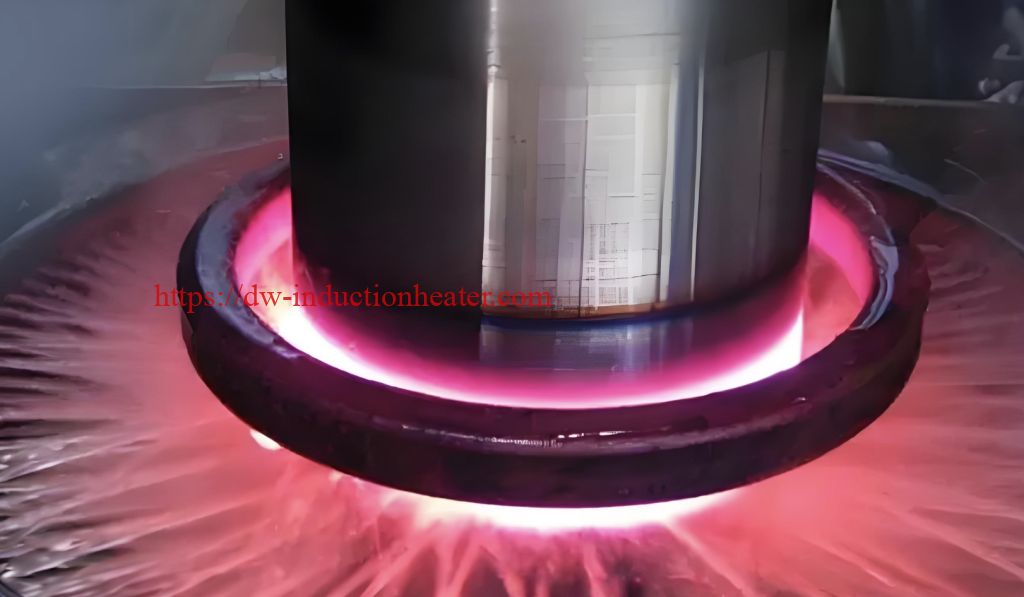

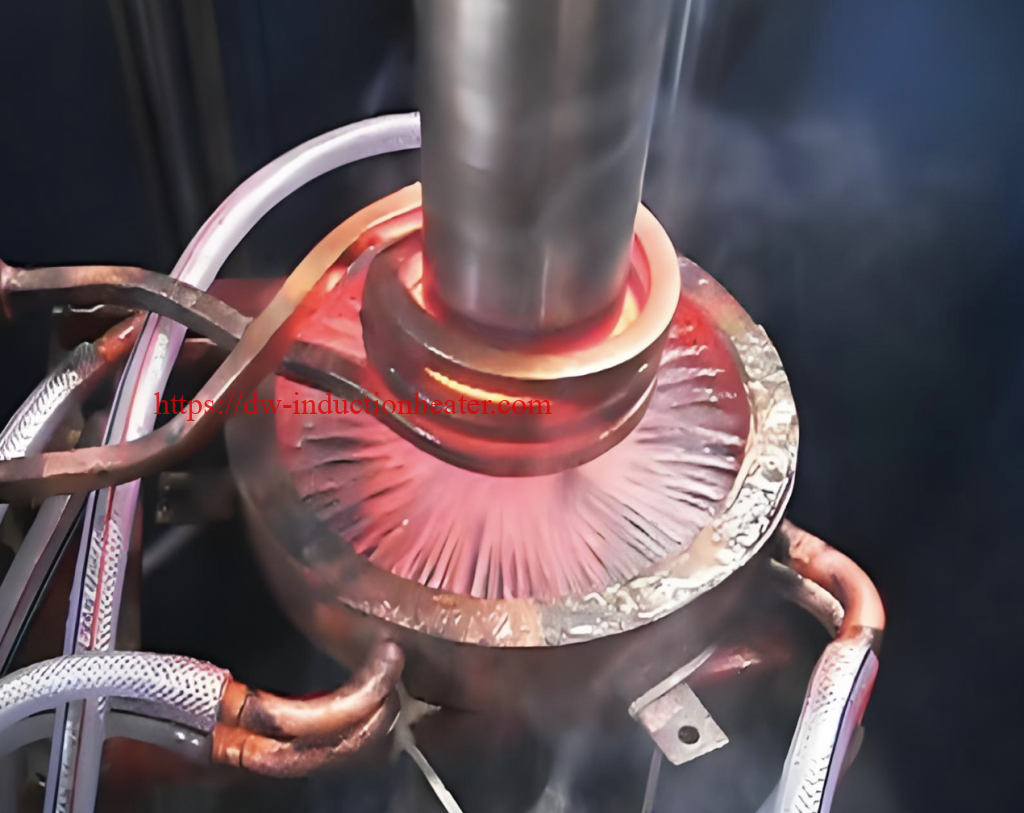

Induction hardening is a heat treatment process that uses high-frequency electromagnetic fields to rapidly heat the surface of a metal workpiece. This targeted heating, followed by controlled cooling (quenching), creates a hardened surface layer with improved wear resistance and fatigue strength.

- What makes induction hardening so beneficial?

- Enhanced Durability:Significantly increases wear resistance and fatigue strength compared to untreated metal.

Precision Control:Allows for precise control over the depth and area of hardening, minimizing distortion.

Precision Control:Allows for precise control over the depth and area of hardening, minimizing distortion.- Increased Efficiency:A rapid process that saves time and energy compared to traditional heat treatment methods.

- Versatility:Suitable for a wide range of components, especially gears, shafts, and other wear-prone parts.

- Environmentally Sound:A clean process with minimal environmental impact.

- Which materials are compatible with induction hardening?

Induction hardening is most effective on medium to high carbon steels (above 0.35% carbon). It also works well with various ferrous alloys, including cast iron and some types of stainless steel.

- What are the most common applications of induction hardening?

You’ll find induction hardening used across diverse industries:

- Automotive:Gears, axles, camshafts, and other drivetrain components.

- Aerospace:Landing gear, engine parts, and other high-stress components.

- Manufacturing:Cutting tools, dies, molds, and other wear-resistant tools.

- Agriculture:Tillage tools, harvesting equipment, and other heavy-duty machinery.

- How deep can induction hardening penetrate a material?

The depth of hardening is influenced by factors like material properties, frequency of the electromagnetic field, power applied, and heating duration. Typically, depths ranging from 0.5mm to 10mm can be achieved.

- What distinguishes induction hardening from case hardening?

Both processes harden the surface, but their mechanisms differ:

- Induction hardeninguses localized heating and rapid cooling to transform the surface layer’s microstructure.

- Case hardeninginvolves altering the surface layer’s chemical composition by diffusing carbon or nitrogen into it.

- Are there any limitations to induction hardening?

Material Constraints: Most effective on ferrous alloys with sufficient carbon content.

Shape Limitations: Complex geometries can pose challenges for uniform heating.

Surface Quality: Surface cleanliness and quality are crucial for effective hardening.

Cost Factor: The initial investment in equipment can be higher compared to some other heat treatment methods.

- What factors influence the hardness achieved in induction hardening?

Several factors play a role:

Material Composition: Carbon content and alloying elements significantly impact achievable hardness.

Heating Rate and Temperature: Precise control over these parameters is crucial for optimal hardness.

Quenching Rate: Rapid cooling is essential to “freeze” the desired hardened microstructure.

Induction Coil Design: The shape and design of the coil influence the heating pattern and efficiency.

- What types of induction hardening equipment are available?

Stationary Equipment: Used for hardening specific areas of large or heavy workpieces.

Progressive Scanners: Ideal for hardening long parts like shafts or rods.

Contour Hardening Systems: Designed for hardening complex shapes by following the workpiece contour.

Computer Numerical Control (CNC) Systems: Offer high precision and repeatability for automated processes.

- How is the quality of induction hardening ensured?

Various quality control measures are employed:

Hardness Testing: Measuring surface hardness using methods like Rockwell or Vickers testing.

Microstructure Analysis: Examining the hardened layer under a microscope to verify the desired microstructure.

Case Depth Measurement: Determining the depth of the hardened layer using techniques like eddy current testing.

Process Monitoring: Real-time monitoring of parameters like current, frequency, and temperature to ensure consistency.

Induction hardening is commonly used for parts that undergo heavy surface wear but need to maintain a tough interior, such as gears, shafts, bearings, and automotive components. The process is precise and can be localized to specific areas of the component, which helps in minimizing distortion and conserving material properties in areas that do not require hardening.