Objective

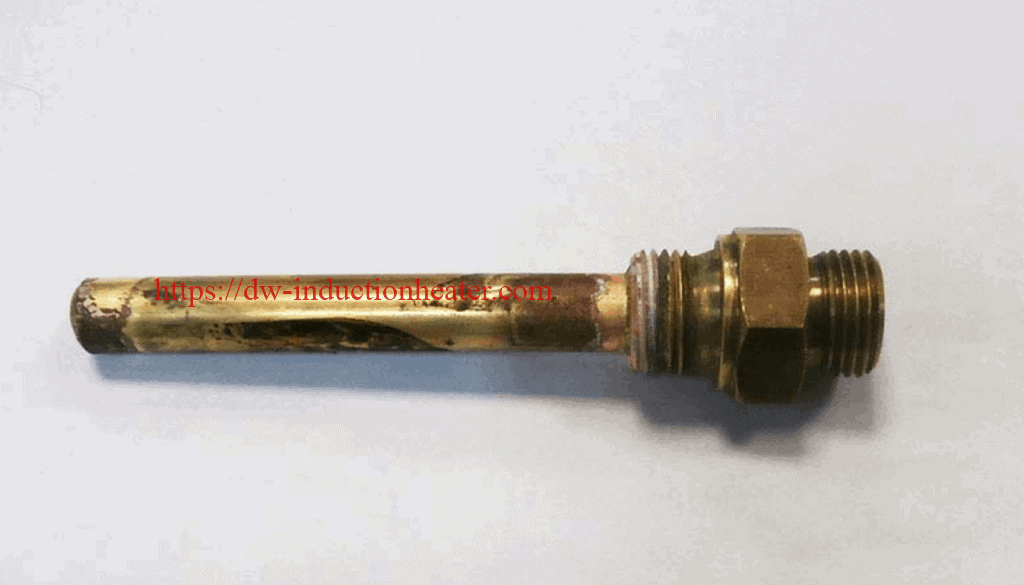

High Frequency Induction Brazing brass pipe to brass part and a brass tip in under one minute using induction.

Equipment

DW-UHF-6KW-III handheld induction brazing machine

2 turns coil

Materials

• Wide brass part

• Brass pipe

• Silver-based brazing alloy, provided by customer

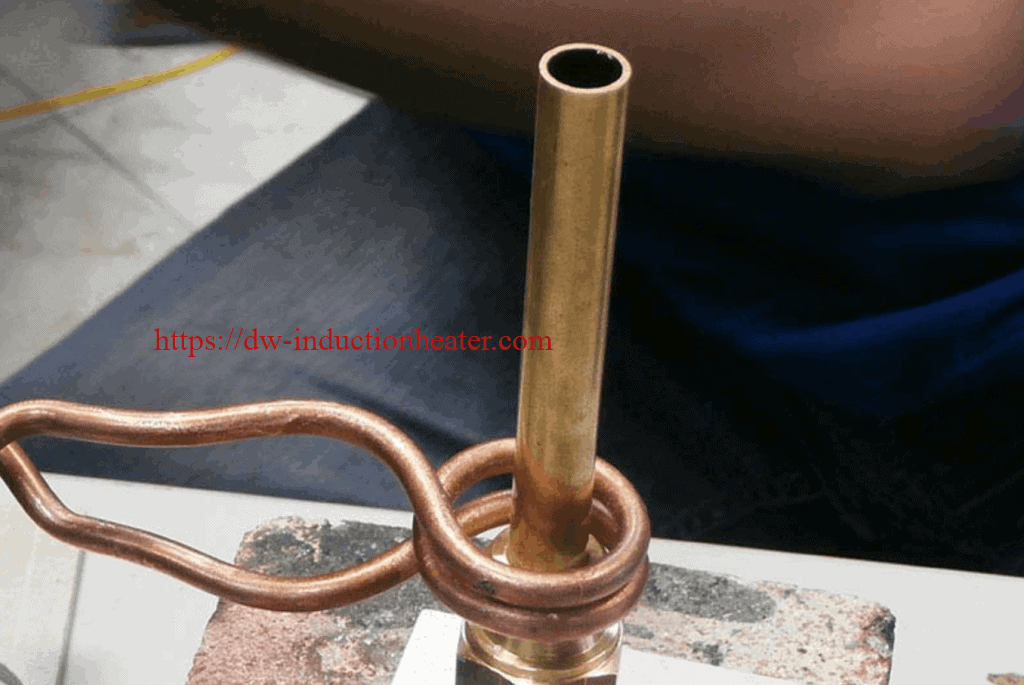

Test 2 – Pipe to tip:

Key Parameters

Power: 4.4 kW

Temperature: Approximately 1400° F (760° C)

Time: 17 sec

Process:

Test 1

- The wide part and brass pipe are assembled and a brazing alloy ring is placed between them.

- The assembly is put inside the induction heating coil and induction heat is applied.

- The joint is completed in 38 seconds.

Test 2

- The tip and pipe are assembled and a brazing alloy ring is placed between them.

- The assembly is put inside the coil and induction heat is applied.

- The joint is completed in 17 seconds.

Results/Benefits:

Induction heating provides:

- Strong durable joints

- Selective and precise heat zone, resulting in less part distortion and joint stress than welding

- Less oxidation

- Faster heating cycles

- More consistent results and suitability for large volume production, without the need for batch processing

- Safer process than flame brazing