-

1/6

-

2/6

-

3/6

-

4/6

-

5/6

Straightening of Construction and Structural Engineering with Induction Heating Systems

Straightening of Construction and Structural Engineering with Induction Heating Systems

Steel structures and components play a pivotal role in construction and structural engineering. Over time, or during fabrication, these elements often become distorted due to welding, stress, or environmental impacts—demanding efficient and precise straightening methods. Enter induction heating systems, a revolutionary solution that excels in straightening construction and structural engineering components with unmatched speed, accuracy, and energy efficiency.

In this comprehensive guide, we delve deep into how induction heating systems are used for the straightening process, their benefits, applications, and why they are replacing traditional methods across industries.

Table of Contents

Straightening of Construction and Structural Engineering with Induction Heating Systems

What is Straightening in Construction and Structural Engineering?

Challenges in Traditional Straightening Methods

Overview of Induction Heating Systems

Key Components of an Induction Heating System:

How Induction Heating Works for Straightening

Key Benefits of Induction Heating for Structural Straightening

Applications of Induction Heating in Construction and Structural Engineering

Straightening Steel Beams and Columns

Correcting Weld-Induced Distortions

Shipbuilding Framework Alignment

Induction Heating vs. Flame Heating: A Detailed Comparison

Energy and Cost Efficiency of Induction Heating Straightening

Environmental Impact and Workplace Safety

FAQs about Induction Heating Systems for Structural Straightening

- How accurate is induction heating for straightening steel components?

- Can induction heating be used on non-ferrous metals?

- Is induction heating cost-effective?

- Does induction heating weaken steel properties?

- What industries benefit most from induction heating systems?

What is Straightening in Construction and Structural Engineering?

Straightening is the process of correcting distortions, bends, or misalignments in structural steel and other construction materials. These deformations can occur during fabrication, handling, or welding, adversely affecting the accuracy, load-bearing capacity, and overall integrity of the structure. Straightening ensures that materials conform to required tolerances, shapes, and alignment specifications, which is essential for structural integrity.

Precision straightening is particularly vital in industries like construction, shipbuilding, railway infrastructure, and bridges, where misalignment can compromise safety and performance.

Challenges in Traditional Straightening Methods

For decades, traditional methods such as flame heating, hydraulic presses, and mechanical techniques have been used to correct steel distortions. However, these approaches come with significant drawbacks:

- Inconsistent Results: Flame heating often leads to uneven temperature distribution, resulting in varying outcomes.

- Time-Consuming: Mechanical and flame-based methods can be labor-intensive, requiring prolonged application to achieve desired results.

- Material Damage: Overheating or excessive pressure can weaken materials, affecting their long-term durability.

- Safety Concerns: Open flames present higher risks of workplace accidents and environmental hazards.

- High Energy Consumption: Traditional methods often demand significant energy, increasing operational costs.

To overcome these challenges, industries are turning to induction heating systems, which offer precision and efficiency.

Overview of Induction Heating Systems

Induction heating systems utilize electromagnetic induction to generate heat within the material itself, rather than applying heat externally. This heating process is fast, localized, and highly controllable, making it ideal for applications where precision is critical.

In straightening applications, induction heating systems focus the heat directly on the distortion area, causing molecular-level changes to relieve stress or reshape the material without additional damage.

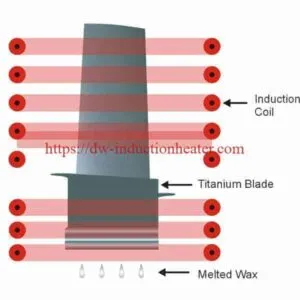

Key Components of an Induction Heating System:

- Induction Coil: Generates the electromagnetic field to induce heat in the material.

- Power Source: Converts electric energy to high-frequency AC current required by the system.

- Control Unit: Regulates the heat intensity, timing, and localization for precise applications.

How Induction Heating Works for Straightening

Induction heating relies on electromagnetic fields to heat steel or other conductive materials. Here’s a step-by-step breakdown of how the process works for straightening:

- Target Area Identification: Distorted regions or bends are marked for induction heating application.

- Placement of Coil: An induction coil is placed around or near the target area.

- Heat Generation: High-frequency alternating current generates an electromagnetic field, inducing heat directly in the material.

- Controlled Expansion and Relaxation: The localized heat causes controlled expansion. As the material cools, it relaxes into its corrected shape.

- Final Inspection: Engineers validate the straightened structure using lasers or gauges.

Unlike other techniques, induction heating ensures that only the required area is altered, preserving material properties and integrity throughout the process.

Key Benefits of Induction Heating for Structural Straightening

- Precision Heating: Heat is localized to specific areas, eliminating the risk of widespread material damage.

- Reduced Cycle Times: Faster application compared to flame heating or mechanical methods.

- Energy Efficiency: Minimal heat loss results in notable energy savings.

- Non-Contact Method: No direct contact reduces risk of contamination or material degradation.

- Operator Safety: No open flames or hazardous fumes ensure a safer working environment.

- Material Preservation: Induction heat minimizes residual stresses, preserving structural strength and lifespan.

Applications of Induction Heating in Construction and Structural Engineering

Induction heating systems are essential in industries where structural performance is non-negotiable. Here are some key applications:

Straightening Steel Beams and Columns

Steel beams often warp during construction due to welding or thermal stress. Induction heating corrects these distortions with unmatched accuracy, making it a preferred method for aligning beams and columns in infrastructure projects.

Correcting Weld-Induced Distortions

Welding creates intense localized heat, leading to uneven contraction during cooling. Induction heating can realign these distortions, ensuring proper joint tolerances without weakening weld integrity.

Railway Track Adjustment

Railway tracks must maintain precise alignment for safety and efficiency. Induction heating enables quick adjustments to track curvature or misalignments, reducing downtime and enhancing safety.

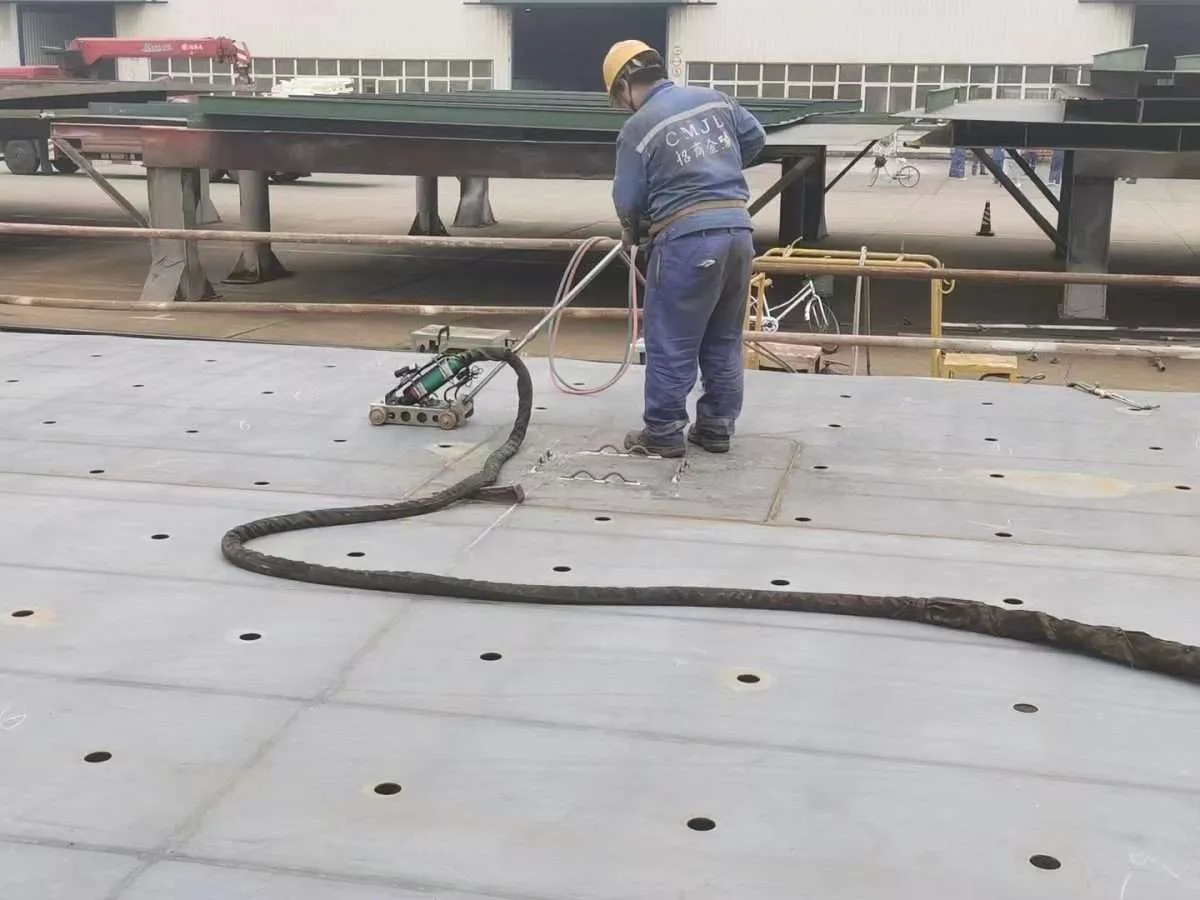

Shipbuilding Framework Alignment

In shipbuilding, heavy steel plates and frames often require straightening. Induction heating systems streamline this process, reducing construction time while maintaining compliance with strict engineering specifications.

Induction Heating vs. Flame Heating: A Detailed Comparison

| Feature | Induction Heating | Flame Heating |

| Heat Source | Electromagnetic induction | Open flame |

| Heating Speed | Fast and instantaneous | Moderate to slow |

| Precision | Highly localized | Generalized heat |

| Safety | No open flames, safer workplace | High risk of fire or burns |

| Energy Consumption | Efficient with minimal loss | High energy demand |

| Environmental Impact | Eco-friendly | Produces emissions |

Energy and Cost Efficiency of Induction Heating Straightening

Induction heating systems drastically lower energy costs compared to traditional flame heating. By directly heating the material, energy waste is minimized. Additionally, the speed and precision of induction methods lead to shorter production cycles, reducing labor costs and increasing overall profitability.

Environmental Impact and Workplace Safety

With industries moving towards greener solutions, induction heating stands out as an environmentally friendly alternative. Key advantages include:

- No Combustion: No CO₂ or toxic gases are released.

- Reduced Noise Pollution: Quiet operations improve workplace comfort.

- Improved Worker Safety: Eliminates risks from open flames and hot surfaces.

These benefits help companies meet stringent environmental regulations and build a safer workplace culture.

FAQs about Induction Heating Systems for Structural Straightening

1. How accurate is induction heating for straightening steel components?

Induction heating provides pinpoint accuracy, ensuring that only the target area is affected while preserving surrounding regions’ structural integrity.

2. Can induction heating be used on non-ferrous metals?

Induction heating works primarily on ferrous metals due to their higher magnetic permeability. However, with the right configuration, it can be adapted for some non-ferrous applications.

3. Is induction heating cost-effective?

Yes, induction heating reduces energy use, shortens cycle times, and minimizes labor, making it a highly cost-effective straightening solution.

4. Does induction heating weaken steel properties?

No, induction heating is a controlled process that avoids overheating, ensuring material strength and durability remain intact.

5. What industries benefit most from induction heating systems?

Induction heating is widely used in construction, shipbuilding, railway, automotive, and manufacturing industries for precise straightening and heat treatment.

Conclusion

Induction heating systems have revolutionized the way we approach straightening in construction and structural engineering. With unparalleled precision, rapid application, and eco-friendly benefits, these systems resolve longstanding challenges posed by traditional methods. By embracing induction heating, industries can achieve higher productivity, lower costs, and superior structural excellence.

As the demand for sustainable and efficient solutions grows, it’s clear that induction heating is paving the way for a smarter and safer future in structural engineering. Don’t get left behind—embrace the advanced capabilities of induction heating today.

STRAIGHTENING OF CONSTRUCTION AND STRUCTURAL ENGINEERING WITH INDUCTION HEATING SYSTEMS