-

1/3

-

2/3

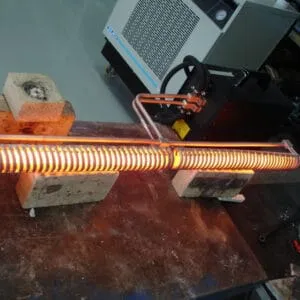

induction heating hot rolling

induction heating hot rolling with IGBT induction heating system

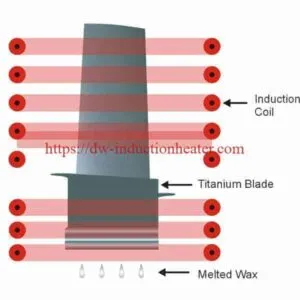

Objective To heat the circumference of plough discs before hot rolling (sharpening) process

Material Flat Boron steel discs, OD 460 to 710 mm (18 to 28”) thickness 3.2 to 10 mm (8/64 to 25/64”)

Temperature 725°C 1335°F

Frequency 75 kHz

Equipment DW-HF-120 kW induction heating system using 2 work heads, switching system, 4 specially-designed coils, chiller system

Process In a PLC system, each of two rolling machines is equipped with a remote work head and with a rotating platform where the disc is held horizontally and held in position by a central nonmagnetic

plate 100 mm less that the disc diameter. The 250 mm (10”) heating coil is positioned over the blade, rotationally ahead of pressure rolls. This heats the entire edge of the disc.

After a few seconds of heating, the edge reaches the required temperature and the disc is made to turn at 30 rpm. The pressure rolls close, forming the sharp edge profile. The final edge is obtained after two turns of the disc.

Results/Benefits Induction heating provides a much more rapid process compared to cold-rolling; the desired profile is achieved after a few seconds, compared with a few minutes. The metallurgical quality of the finished edge is higher, since the process effectively hardens the material.

The equipment and process lend themselves to robotic automation