- 1/3

- 2/3

Induction Heating Wire Stripping

Description

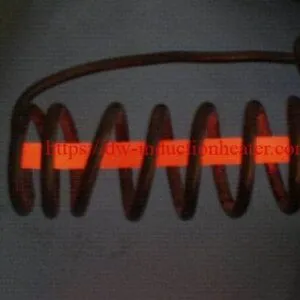

Induction Heating Wire Stripping to Burn off the varnish coating With RF Heating

Objective Heat wires to burn off the varnish coating

Material Flat copper wire bundle of wires with a rectangular crosssection of .025 square inches (.0635 square centimeters)

Temperature 1300°F (704°C) for 5 seconds

Frequency 204 kHz

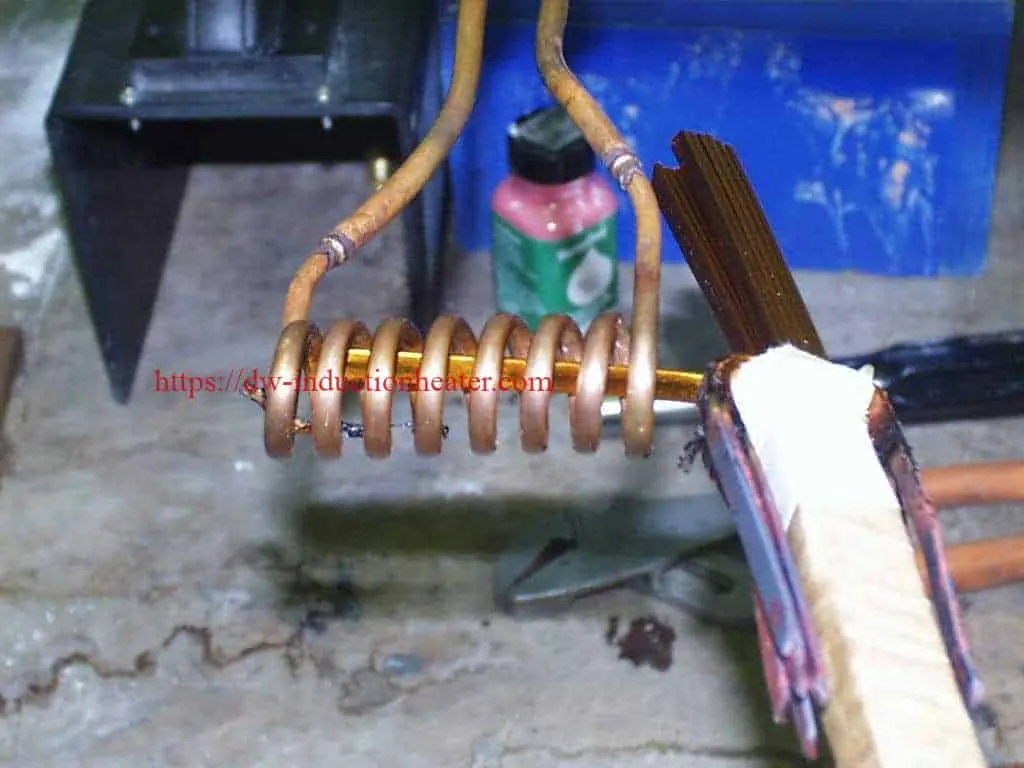

Equipment DW-UHF-10kW induction heating system equipped with a remote heat station, containing (1) 1.00 μf capacitor. An induction heating coil designed and developed specifically

for this application.

Process An eight turn helical coil is used to generate the desired heat pattern. The coil has a 0.62” ID. An individual wire is inserted and heated to burn off the varnish for 5 seconds. Larger cross sectional areas require a longer heat time or higher power.

After the heat cycle, each wire is removed from the coil and allowed to cool at a natural rate.

Results/Benefits Compared to mechanical scraping, induction heating is:

• Faster

• Highly repeatable for consistent results