-

1/3

-

2/3

induction heating graphite carbon

Induction heating graphite carbon with High Frequency induction heating equipment

Objective Heating carbon graphite anodes to destructively oxidize the parts to process embedded contaminants

Material anodes 2.5 x 2.5 x 4 (63 x 63 x 102) h x w x d in (mm)

Temperature 1900 °F 1000°C

Frequency 30 kHz

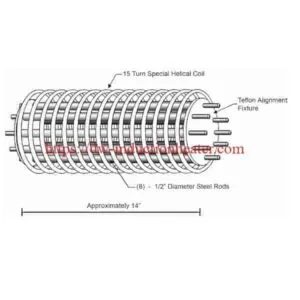

Equipment DW-MF-20kW induction heating system, custom multi-turn helical coil, 4 cap 1.0μF workhead

Process An air purge system is used to provide fresh air (~25 f3/hr) to the part during the heat cycle and to provide a swirling action for maximum contact with the surface of the anode.

The anode is placed inside the induction-heating coil and heated to a temperature of 1000°C. After 2.5 hours, the anode burns to about 0.375 inch diameter piece.

A pyrometer/controller is used to provide constant temperature as the anode reduces in size.

Results/Benefits Induction heating allows this process to be very efficient and controllable