-

1/4

-

2/4

-

3/4

induction preheating aluminum wheels for spray painting

induction preheating aluminum wheels for spray painting

Objective: This spray painting application requires pre-heating the material. Additionally, there is a requirement that the material must not cool below a certain target temperature prior to the spray.

Material : Customer-supplied parts

Temperature :275 ºF (135 ºC)

Frequency :8 kHz

Equipment :

DW-MF-70kW induction heating system, equipped with a remote workhead containing three 27 μF capacitors for a total of 81 μF

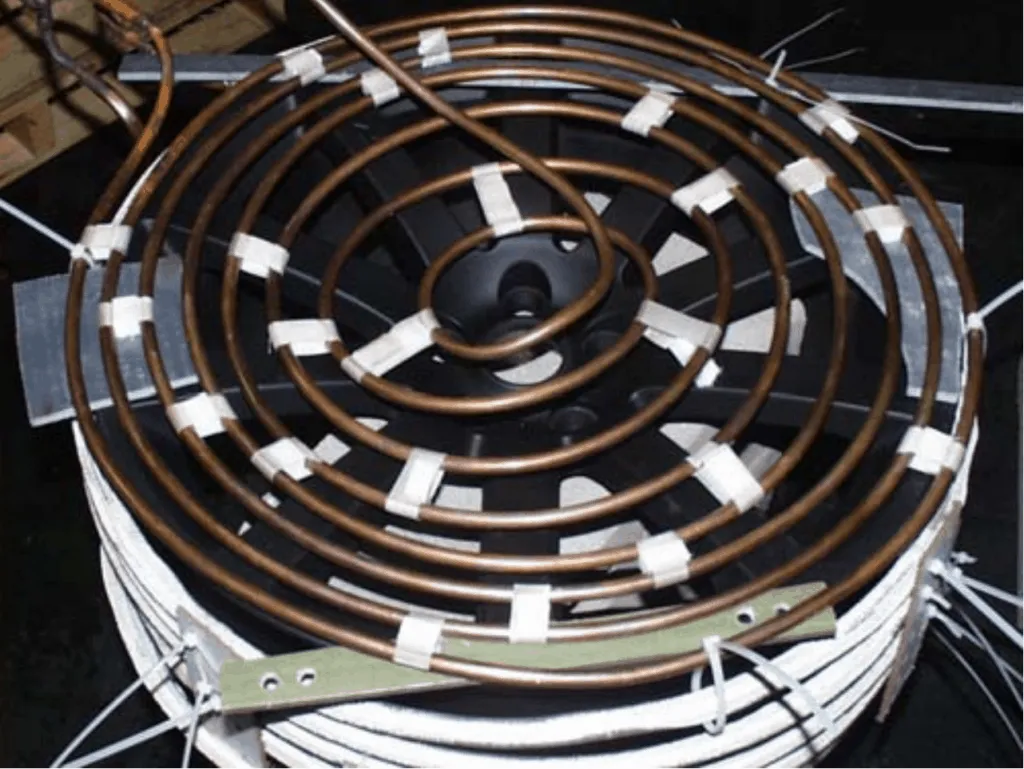

– An induction heating coil designed and developed specifically for this application.

Induction Heating Process

A multi-turn combination helical/pancake coil is used. The 22” aluminum wheel is inserted into the coil and heated for 30 seconds to a temperature of 275 ºF. When heating is halted, the part remains at or above 150 ºF for 108 seconds, fulfilling the target heat requirement.

Results/Benefits Induction heating provides:

-Uniform heat distribution over the wheel

-Precise control of heating and pattern

-Efficiency; reduced energy costs