-

1/3

-

2/3

Induction Heating Aluminum

Induction Heating Aluminum Molds to release baked food with RF induction Equipment

Objective · Heat aluminum cake molds to release baked food products

Material · Aluminum molds 4.5” (11.4 cm) diameter

Temperature 302 °F (150 °C)

Frequency 65 kHz

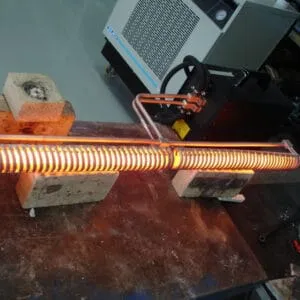

Equipment DW-HF-60kW, induction heating system, equipped with a remote heat station containing eight 1.0 mF capacitors for a total of 8.0 mF

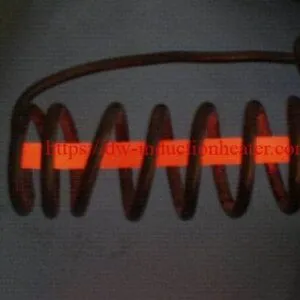

An induction heating coil designed and developed specifically for this application

Process A multi-turn, square pancake coil provides very efficient heating which reduces the cycle time and the conducted heat through the aluminum molds. This coil can be encapsulated in a Teflon/epoxy composite to make it easy to wipe clean. Frozen, pre-baked products are in the cake molds. The molds

are heated as they travel under the induction heating coil to release the product.

Results/Benefits · Induction heating is safer than heating with a convection oven. Grease from the molds causes a fire hazard and waste gases in the oven.

· Quick, clean precision heat for fast cycle times