Objective

High frequency induction brazing carbide to steel.

Recommended Equipment

The recommended equipment for this application is the DW-HF-45KW induction brazing machine with the remote heating station.

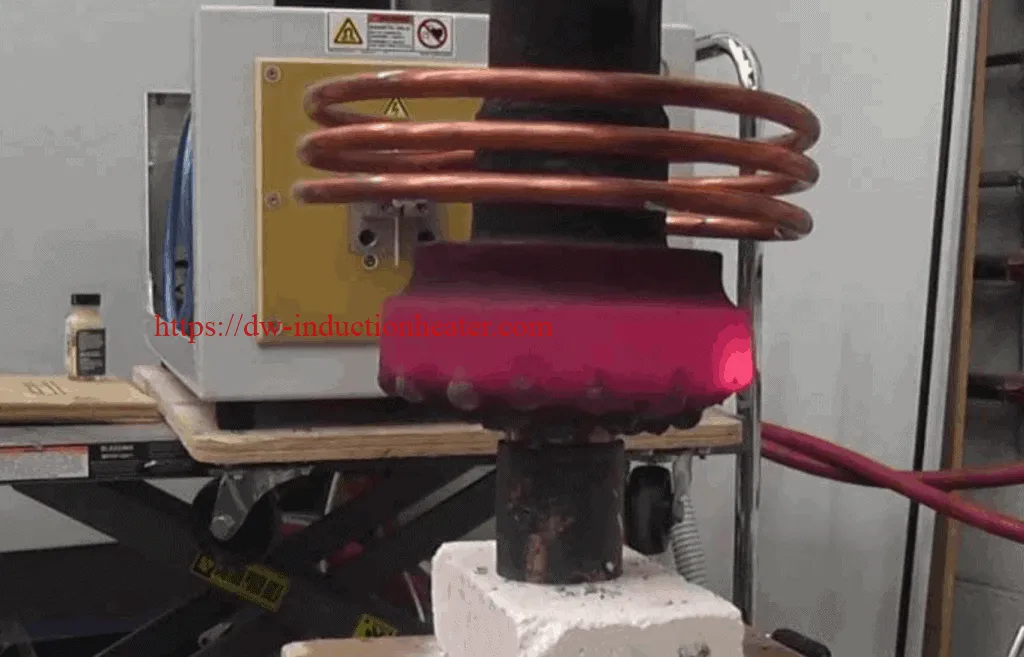

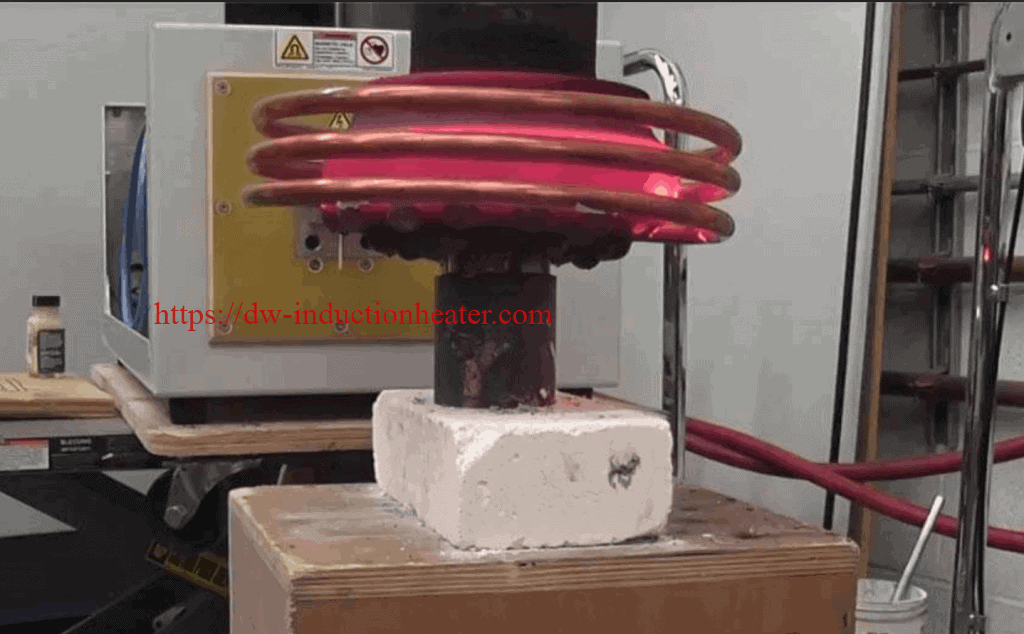

- Large magnetic steel drill head with carbides. Head is approx. 8” OD x 4” (203.2mm OD x 101.6mm) thick, shaft is 11” (279.4mm) long x 2”(50.8mm) to 5” (127mm) OD.

- Carbides 1.125” (28.5mm) long x 0.75”(19.05mm) OD with dome shaped top attached to the head, recessed approx. 0.8” (20.3mm) into the head.

Power: Up to 37kW

Temperature: 1500°F + (815°C+)

Time: Alloy flows at the outer most carbides in 50 seconds. The center and inner carbides start to show alloy dripping at 1 minute and 40 seconds.

Results and Conclusions:

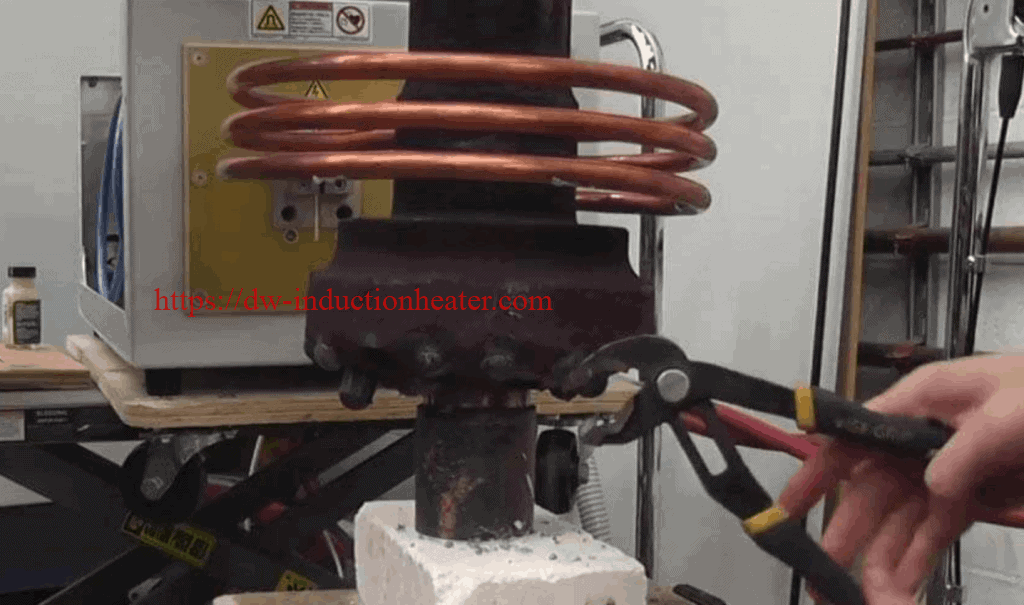

Tests results show that carbide removal is possible. Initially, the part needs to be heated and held at temperature to allow the induction brazing alloy to drip out. It is important to fixture the part with carbides facing down. An external shock is needed afterwards to shift the carbides out enough to allow them to be grabbed with a set of pliers. Caution: when pulling out the carbides, hot molten induction brazing alloy can flow out of the holes for the carbides when they are pulled out.