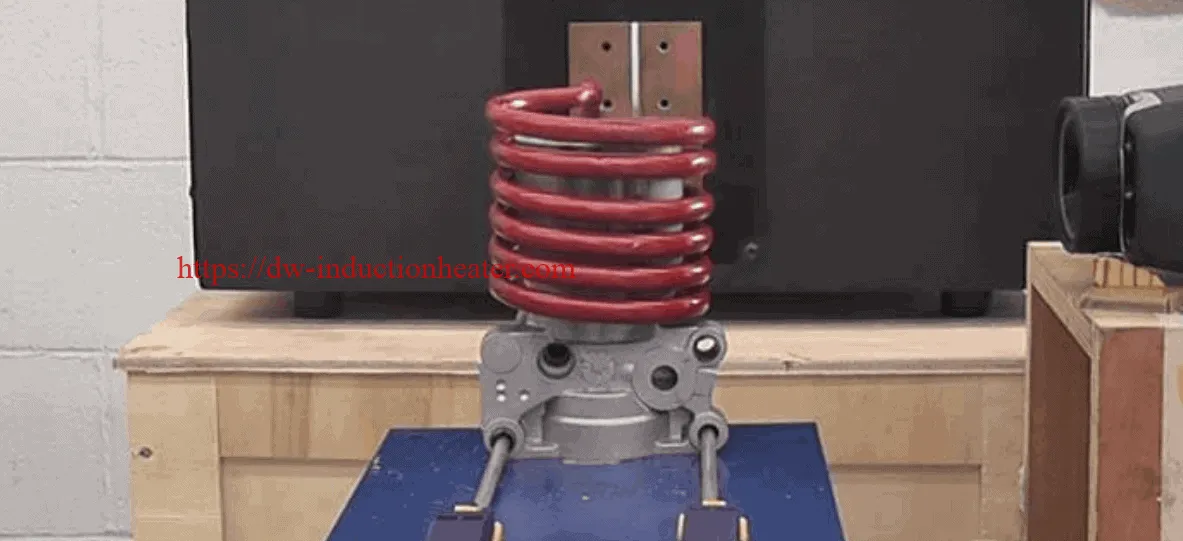

Induction Soldering Copper Wire Connectors

Objective The objective of this application test is to determine heating times for induction soldering copper wire connectors onto a copper coaxial cable. The customer would like to replace hand soldering with soldering irons, with induction soldering. Hand soldering can be labor intensive, and the resulting solder joint is highly dependent on the skill of … Read more