Induction Shrink Fitting For Inserts with IGBT Shrink fitting Heater

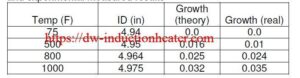

Objective: To heat an aluminum fuel pump housing measuring 8″ x 4 1/2″ x 3 1/2″ to 3750F, allowing steel parts to be inserted. Presently the housings are heated for over one hour in a convection oven. The areas that are to have steel parts inserted measure 1.5″ and 0.6875″ in diameter. In addition, the insertion process lasts for a little over one minute, so 3750F should be maintained for a

period of time to complete the process.

Material: Aluminum Pump Housing measuring 8″ x 4 1/2″ x 3 1/2″

Steel insertion parts.

Temperature: 3750F

Application: By using the DW-HF- 25, 25 kW output solid state induction power supply the following results were achieved.

– 3750F was reached in one (1) minute to allow for insertion.

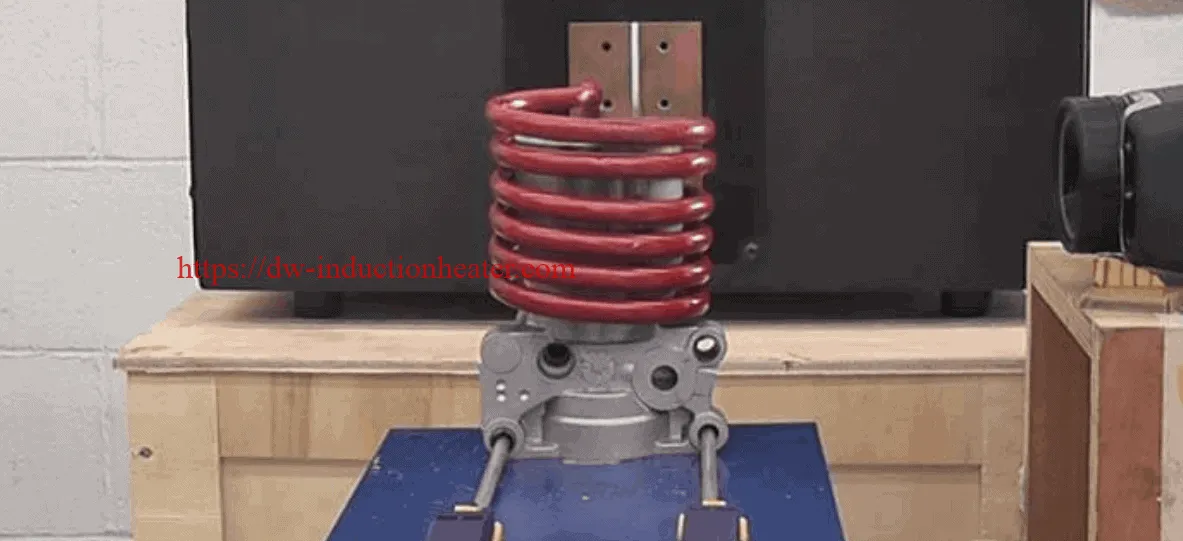

– 20 housings were successfully heated using a five (5) turn right angle pancake coil.

Equipment: Ameritherm SP 25, 25 kW output solid state induction power supply including one (1) remote heat station containing four (4) capacitors totalling 1.0 μF, and a five (5) turn right angle pancake coil made from 3/16″ copper tube.

Frequency: 80 kHz