Induction Shrink Fitting Steel Tube With IGBT Heating Units

Objective Heating a steel tube to 500-1000°F for a shrink-fitting application. Determine expansion (growth) of ID at varying temperatures.

Material Steel tubes 7” OD x 4.75” ID x 5” heat zone

Type ‘K’ thermocouple to measure temperature

Thermal blanket

Temperature 500, 800, 1000 °F (260, 427, 538° C)

Frequency 66 kHz

Equipment DW-HF-7.5, 7.5 kW, 150-400 kHz induction power supply, equipped with a remote heat station containing two 1.5 μF capacitors (for a total of 0.75 μF)

A multi-turn, special series-parallel induction heating coil designed and developed specifically for this application.

Process Initial tests were completed on a sample without a thermal blanket. A thermocouple is slipped between the copper ring and the steel tube to measure temperature. The part measured

4.940” (at room temperature with an ID gauge.) The part reaches 1000°F (538°C) in about 10 minutes.

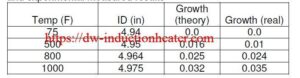

The chart below shows the comparison between theoretical and experimental measured results

Results/Benefits The part measures 4.975” at 1000°F yielding an expansion of 0.035” (4.975 minus 4.94). At 500 and 800°F the expansion numbers were 4.950 and 4.964 respectively. When using a

thermal blanket the heat time is reduced by about 90 seconds (8.5 minutes as opposed to 10 minutes).