Induction Hardening: Maximizing Surface Hardness and Wear Resistance

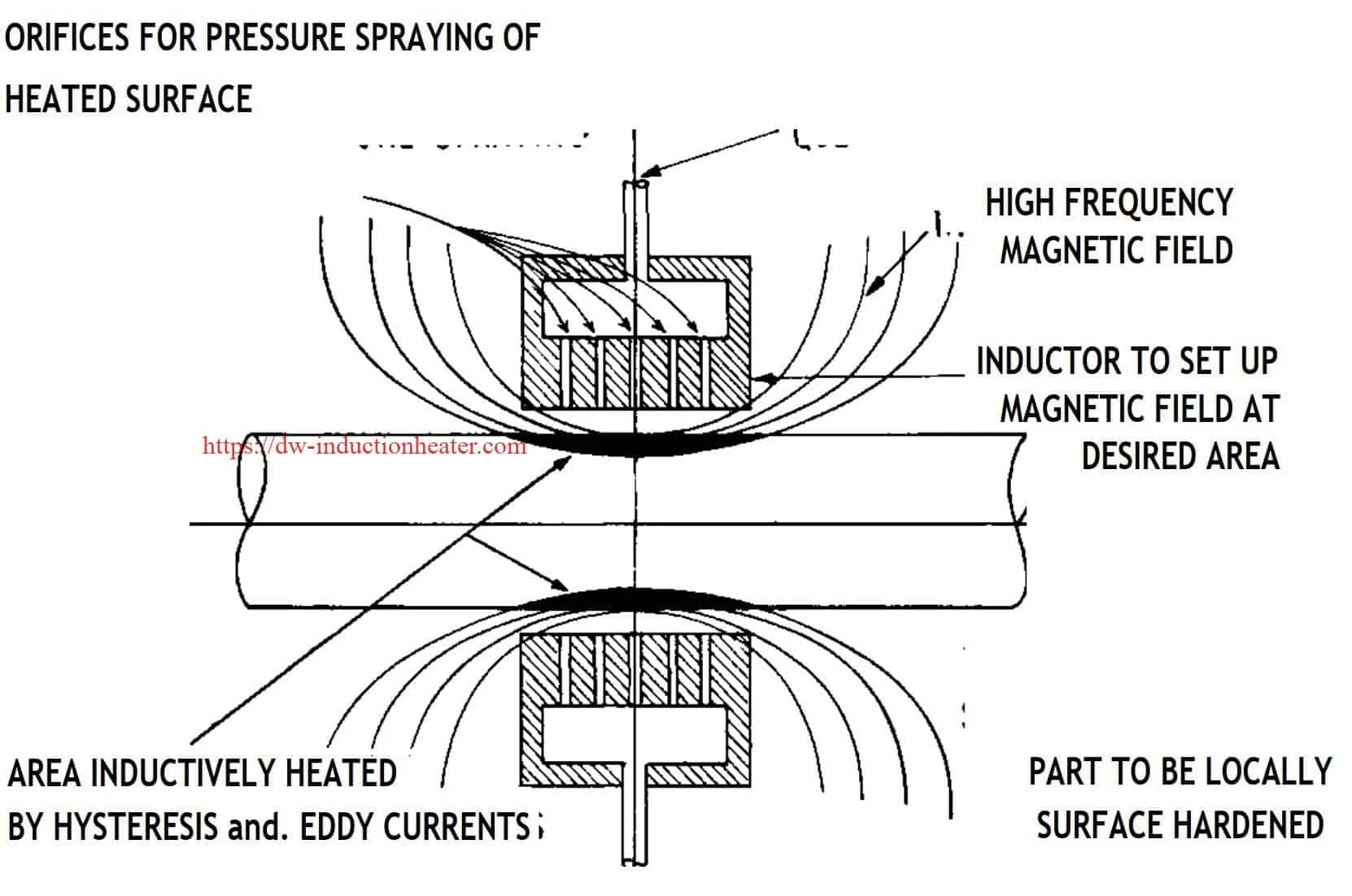

Induction Hardening: Maximizing Surface Hardness and Wear Resistance What is Induction Hardening? The Principles Behind Induction Hardening Electromagnetic Induction Induction hardening is a heat treatment process that selectively hardens the surface of metal components by utilizing the principles of electromagnetic induction. This process involves passing a high-frequency alternating current through an induction coil placed around … Read more