Induction Preheating Hot Heading For Single Rod With IGBT Induction Heater

Objective Heat a waspaloy rod to 1500ºF (815.5ºC) for hot heading application

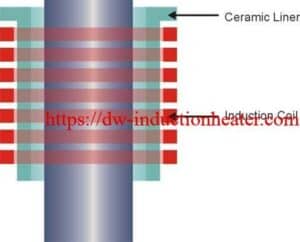

Material Waspaloy rod 0.5” (12.7mm)OD, 1.5” (38.1mm) length, ceramic liner

Temperature 1500 ºF (815.5ºC)

Frequency 75 kHz

Equipment • DW-HF-45KW induction heating system, equipped with a remote workhead containing two 1.32μF capacitors for a total of .66μF

• An induction heating coil designed and developed specifically for this application.

Process A seven turn helical coil is used to heat the rod. The rod is placed inside the coil and power is applied for two seconds providing enough heat to penetrate the inner core. An optical pyrometer is used for close loop temperature control and a ceramic liner is used so the rod does not touch the coil.

Results/Benefits Induction heating provides:

• Low pressure and minimal residual stress

• Better grain flow and microstructure

• Even distribution of heating

• Improved production rates with minimal defects