Induction Annealing Stainless Steel Wire

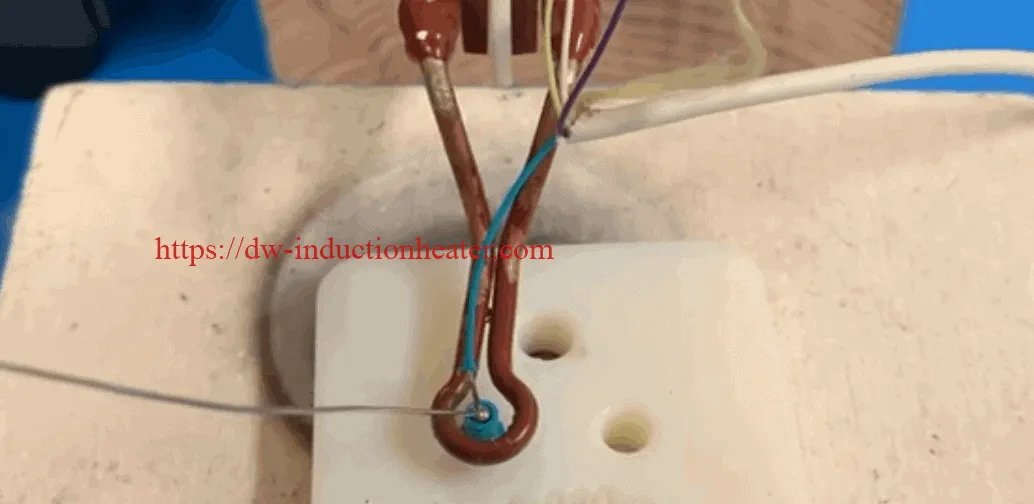

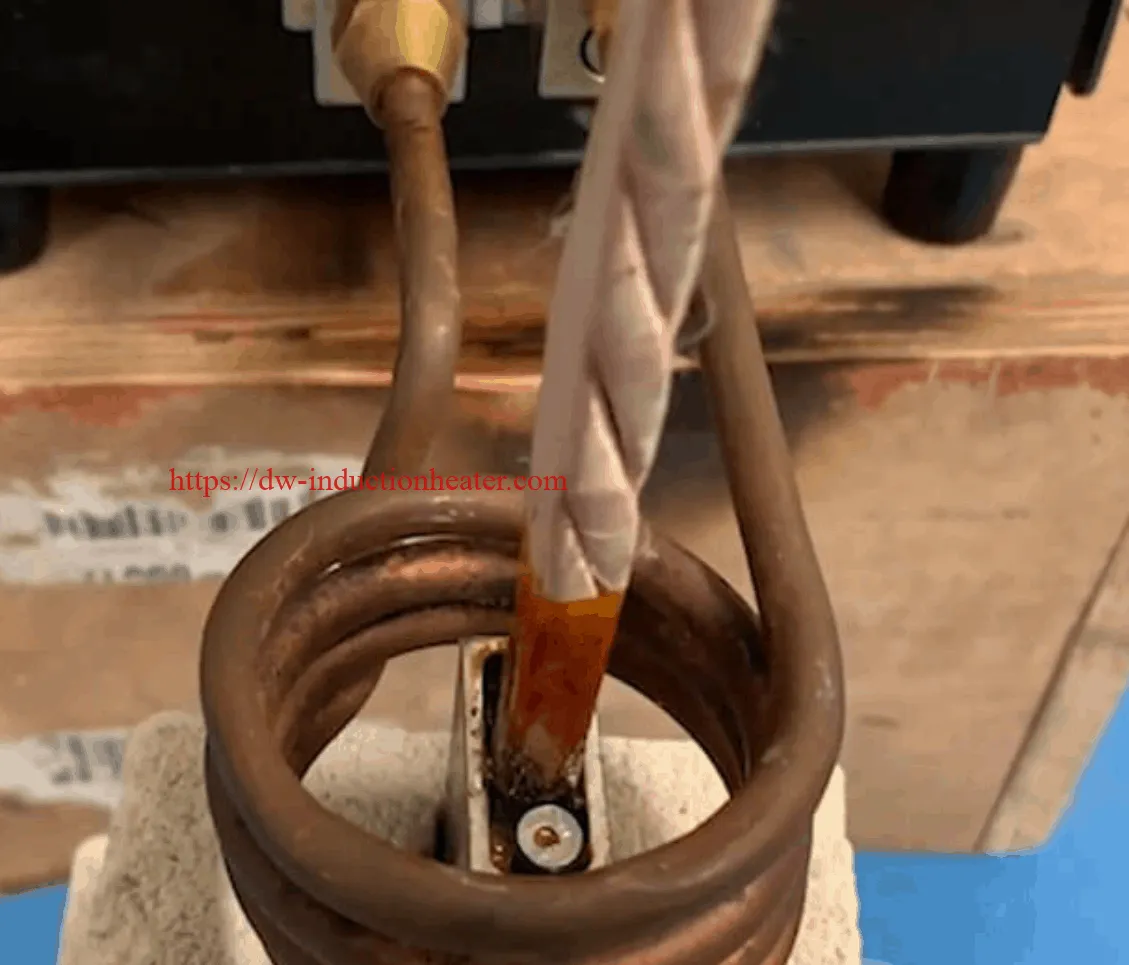

Objective Induction Annealing stainless steel wire in under 1 second with induction. Equipment DW-UHF-10kw induction heater Test I Material Stainless steel Rectangular wire 0.25’’ (6.35mm) Width 0.04’’(1.01mm) Thickness 3.5’’ (88.9mm)Length Key Parameters Power: 5 kW Temperature: 1300°F (704°C) Time: 1 sec Test II Materials Stainless steel Rectangular wire 0.6’’ (15.24mm) Width 0.08’’ (2.03mm) Thickness 1” (25.4mm) … Read more