Induction Shrink Fitting Assemblies

Objective To use induction to prepare cast iron assemblies for shrink fit assembly

Material Customer supplied cast iron rocker arms of varying sizes

Temperature 450 ºF (232 °C)

Process Time 20 seconds

Frequency 148 kHz

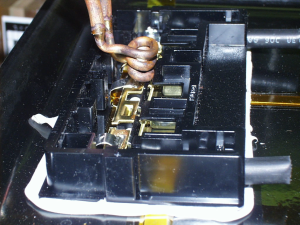

Equipment DW-UHF-5.0 kW, 150-400 kHz solid state induction heating system, equipped with a remote heat station containing one 1.0μF capacitor

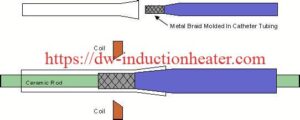

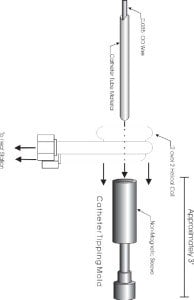

An induction heating coil designed and developed specifically for this application.

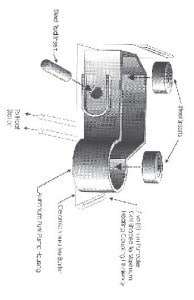

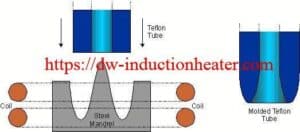

Process A four-turn helical coil heats the ring at one end of the assembly. The coil is designed to concentrate the field towards the center of the assembly where the thermal mass is greatest.

Across the heated ring, the coil presents a lighter field. After heating, a pin is place within the ring and the assembly is water quenched.

The heat time varies from part to part but is less than 20 seconds.

Results/Benefits Induction heating satisfies the needs of this process for:

• rapid part heating

• flexibility for parts of differing geometries

• individual, series part heating, suitable for automation

• a clean source of heat

• even heat distribution