Induction RF Soldering Circuit Board With High Frequency Soldering Heater

Objective Heat a circuit board assembly to 600ºF (315.5ºC) to solder RF connectors to a radar manifold.

Material Kovar connectors 0.100” (2.54mm) wide x 0.200” (5.08mm) long, circuit board and solder paste

Temperature 600ºF (315.5ºC)

Frequency 271 kHz

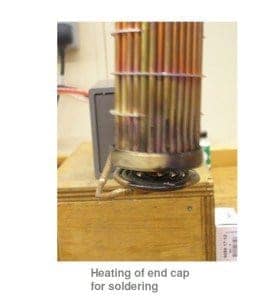

Equipment • DW-UHF-2 kW induction heating system, equipped with a remote workhead containing one 1.2μF capacitor.

• An induction heating coil designed and developed specifically for this application.

Process A two turn helical coil is used to heat the assembly. Solder paste is applied to the joint area, the connectors are placed in the proper location and heat is applied for 10 seconds, creating

the solder paste to flow.

Results/Benefits Induction heating provides:

• Creates liquid and gas-tight joint quickly and efficiently

• Precise application of heat without affecting others areas of board

• Hands-free heating that involves no operator skill for manufacturing

• Even distribution of heating