RPR Induction Stripping-Induction Rust & Paint Coating Removal

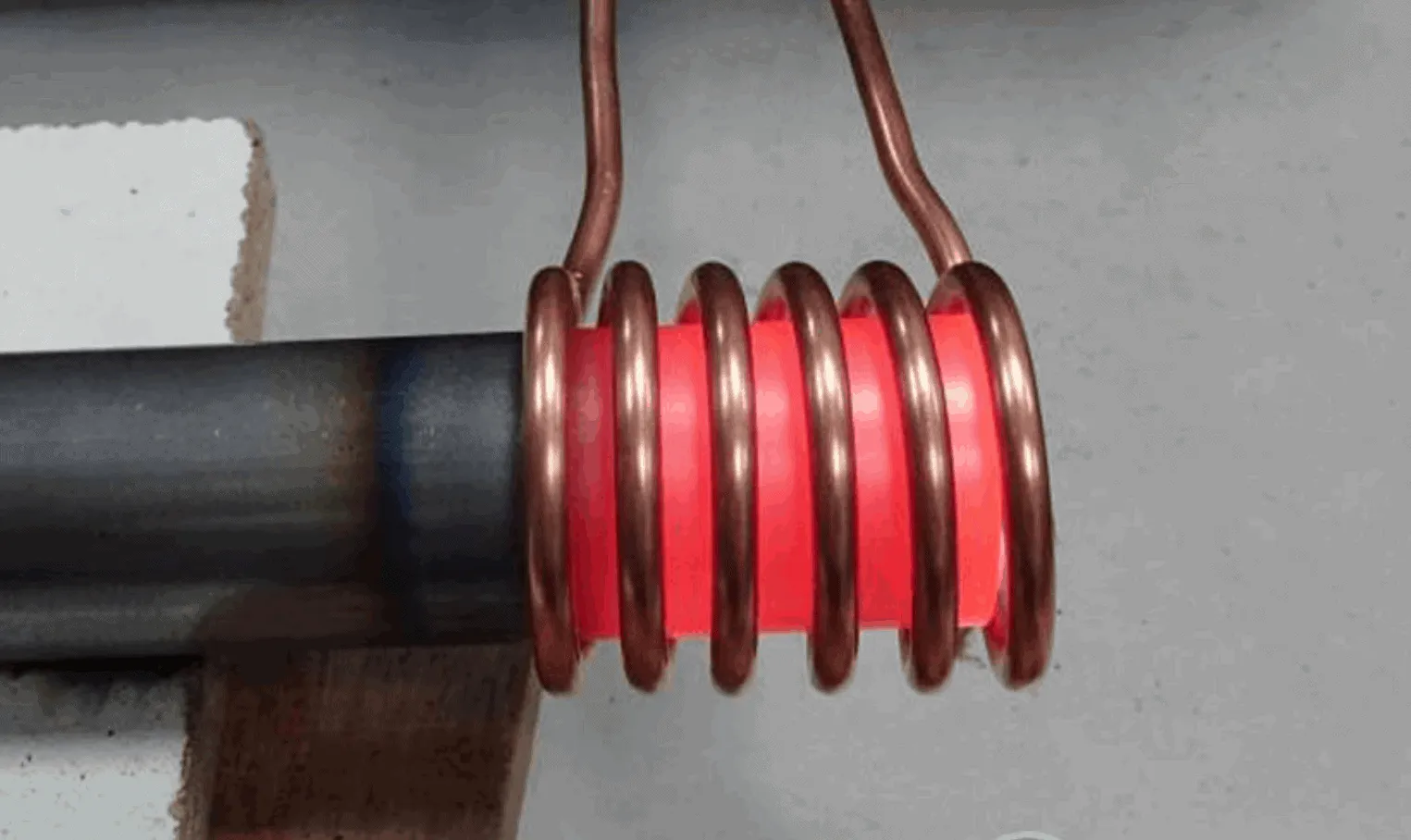

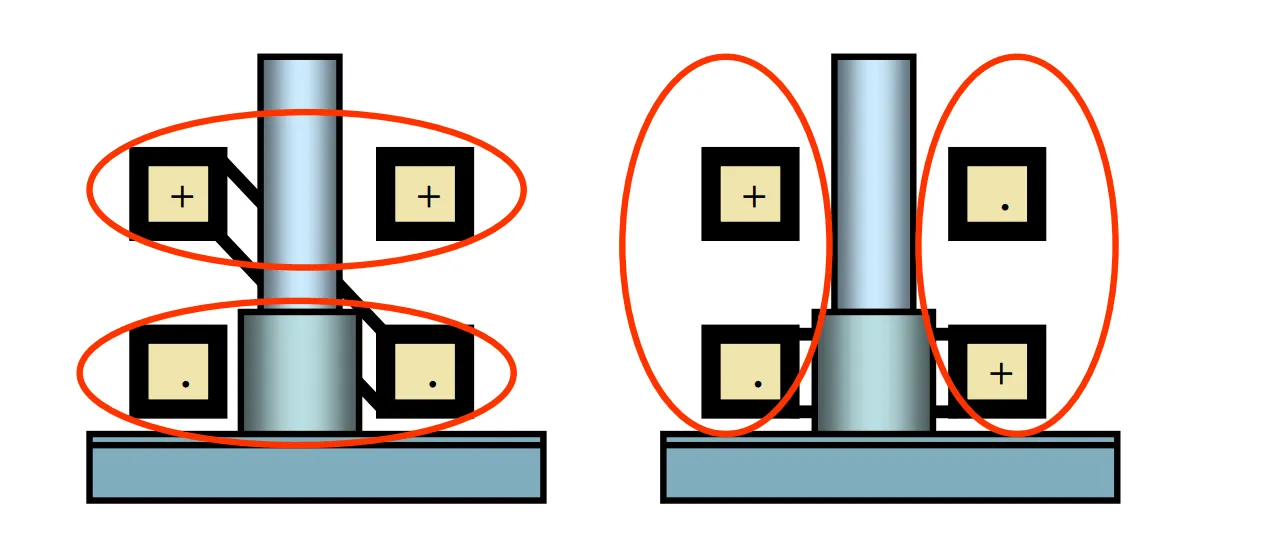

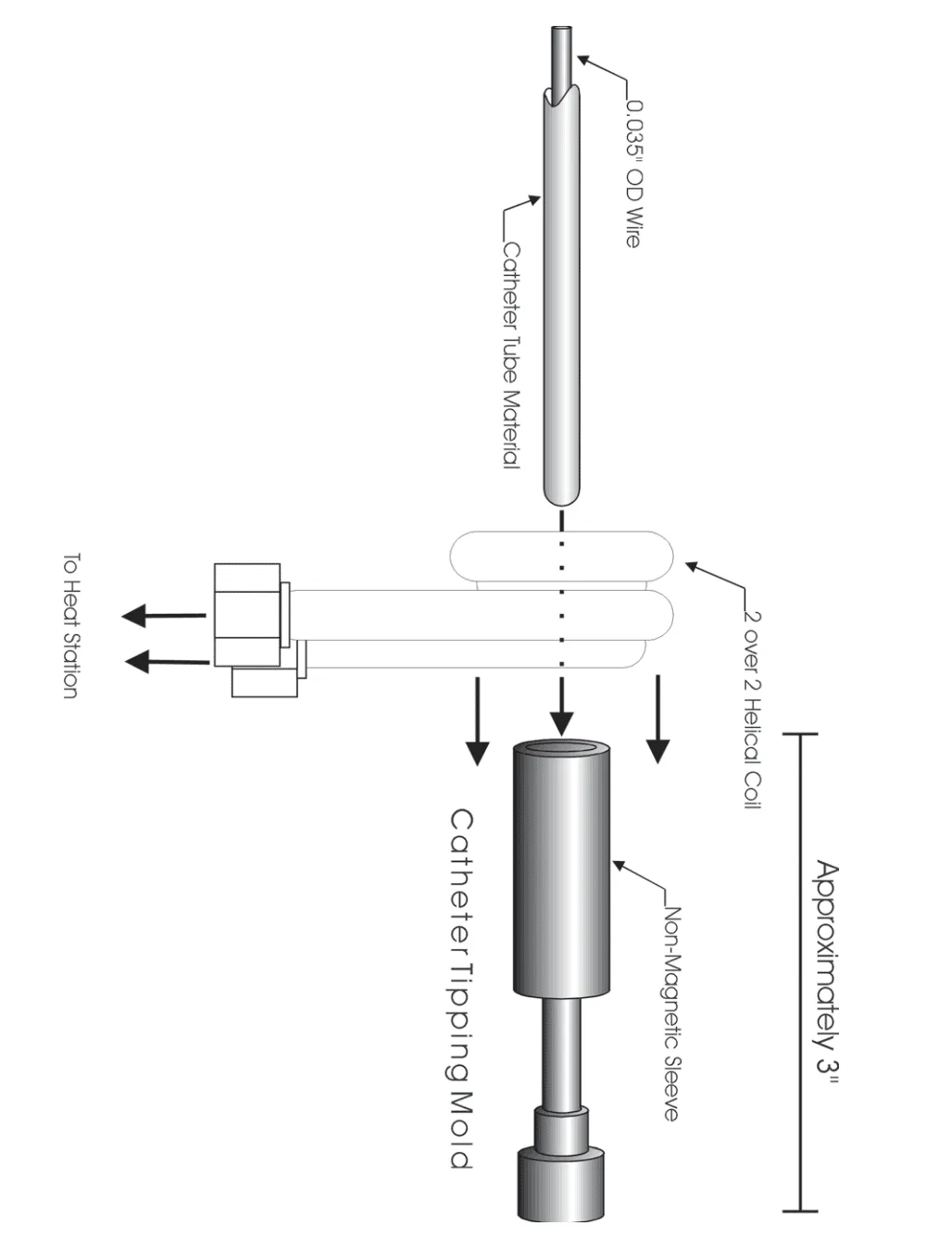

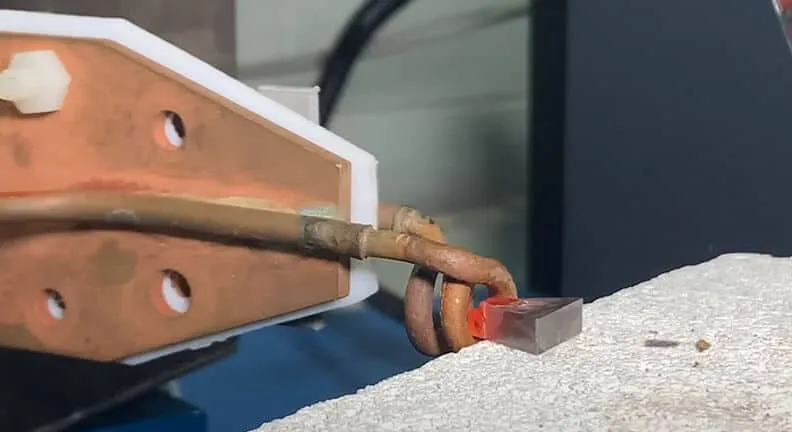

RPR Induction Stripping-Induction Rust & Paint Coating Removal How Induction Stripping Works Induction stripping is a hot surface preparation process.An induction generator sends alternating current through an induction coil, which generates an electromagnetic field. This field induces currents that are converted into heat in contact with conducting materials such as steel. The heat is generated … Read more