Plastic Injection Molding with Induction Heating

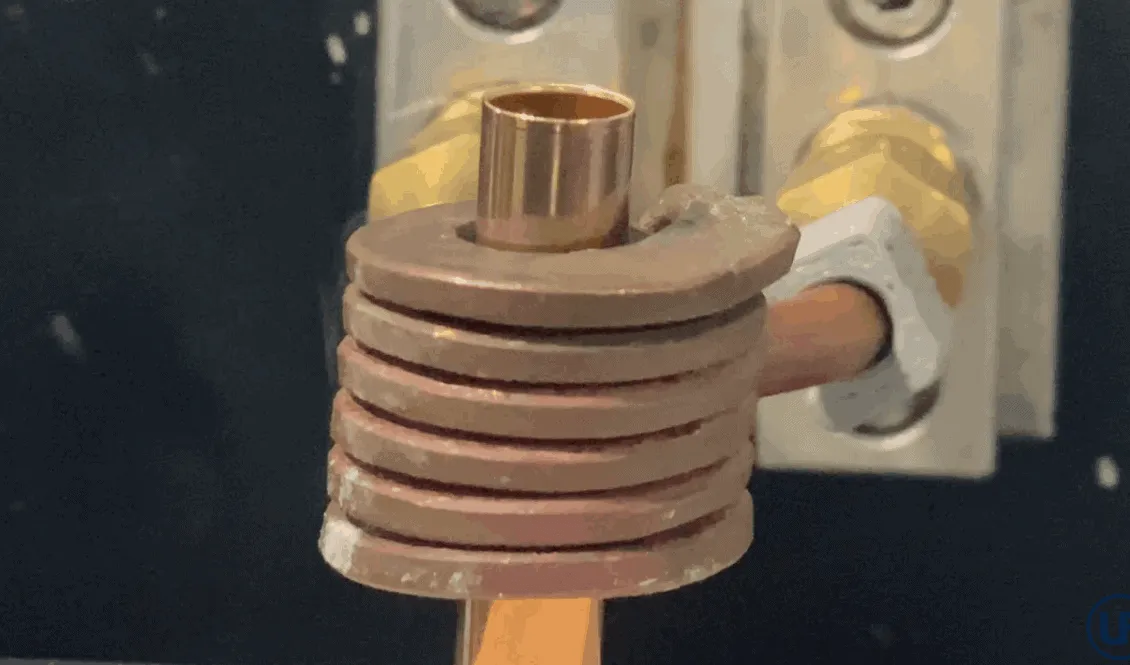

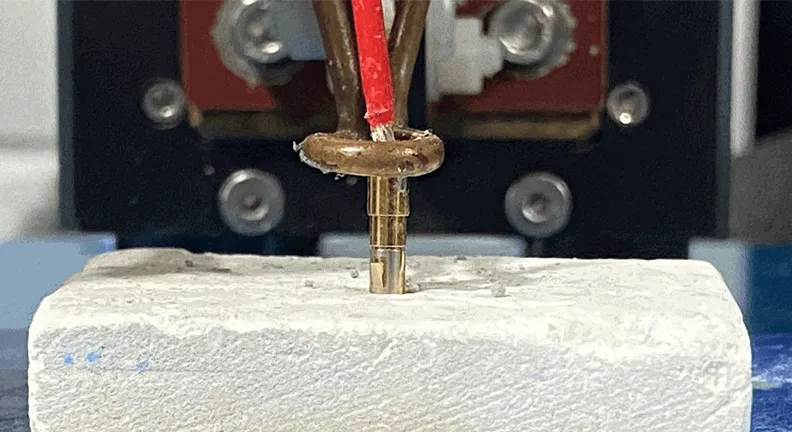

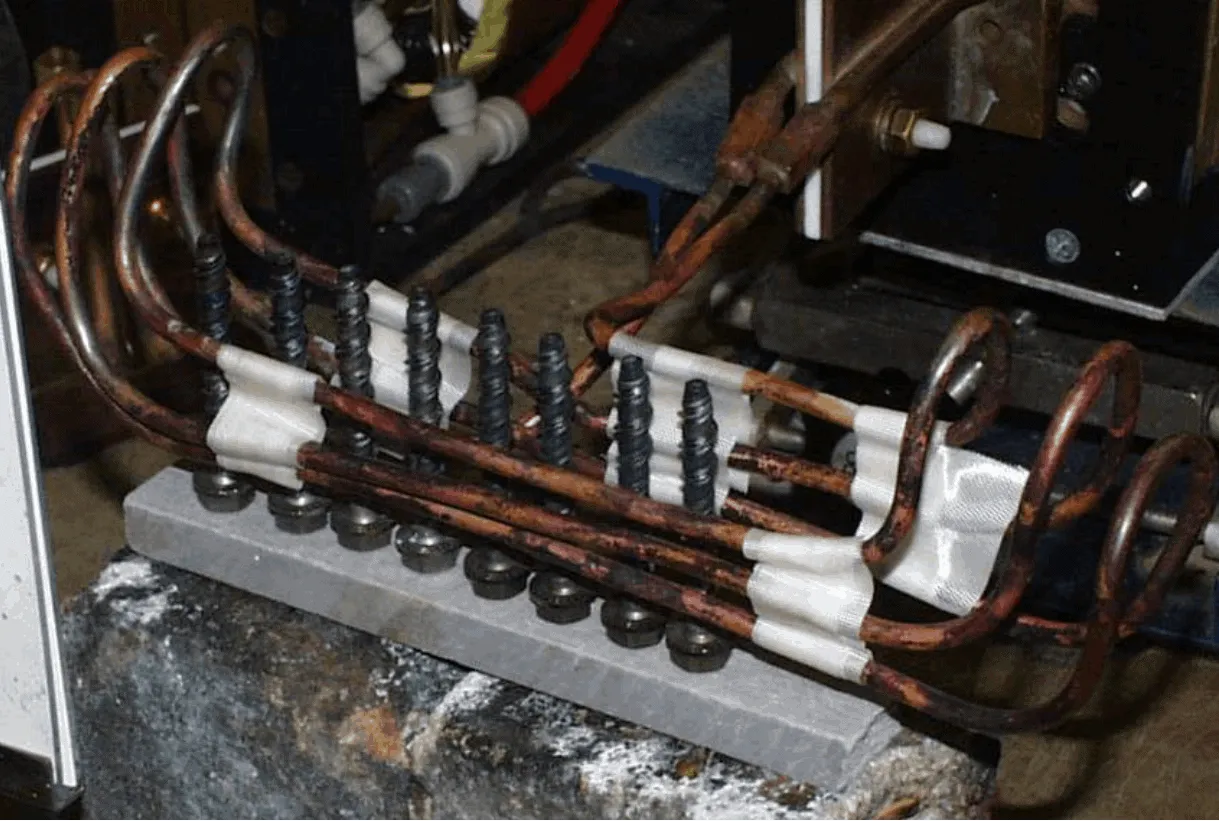

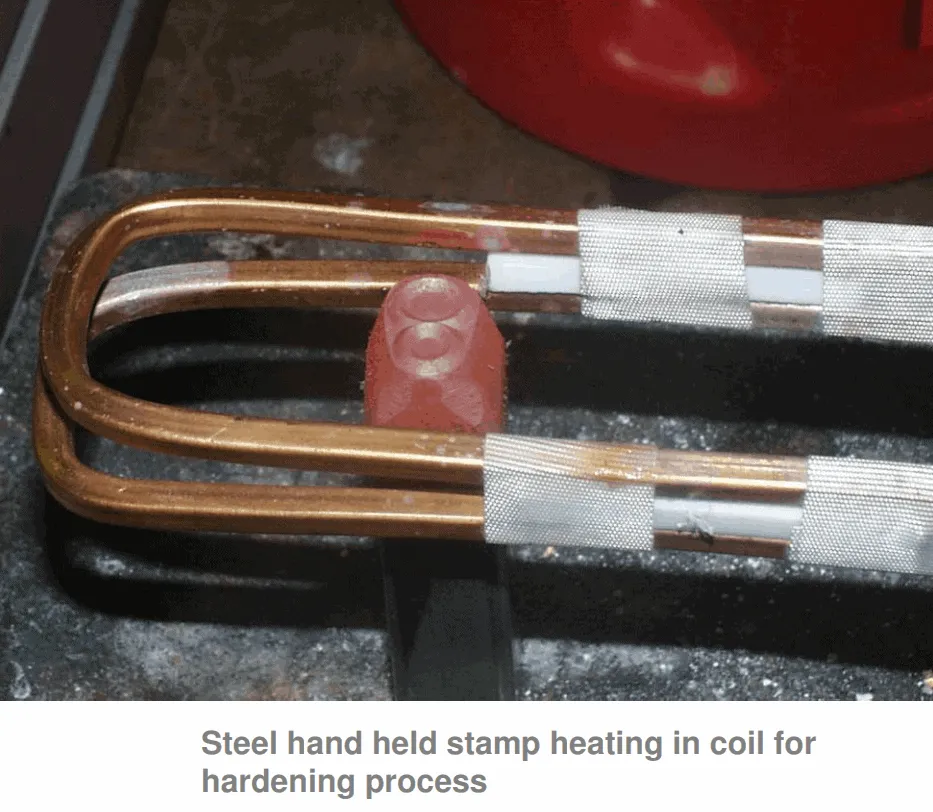

Plastic Injection Molding with Induction Heating Machine Plastic Injection molding with induction heating requires pre-heating of the molds to a higher temperature, to ensure the proper flow or curing of the injection-molded material. Typical heating methods used in the industry are steam or resistive heating, but they are messy, inefficient, and unreliable. Induction heating is … Read more