Induction Hardening and tempering

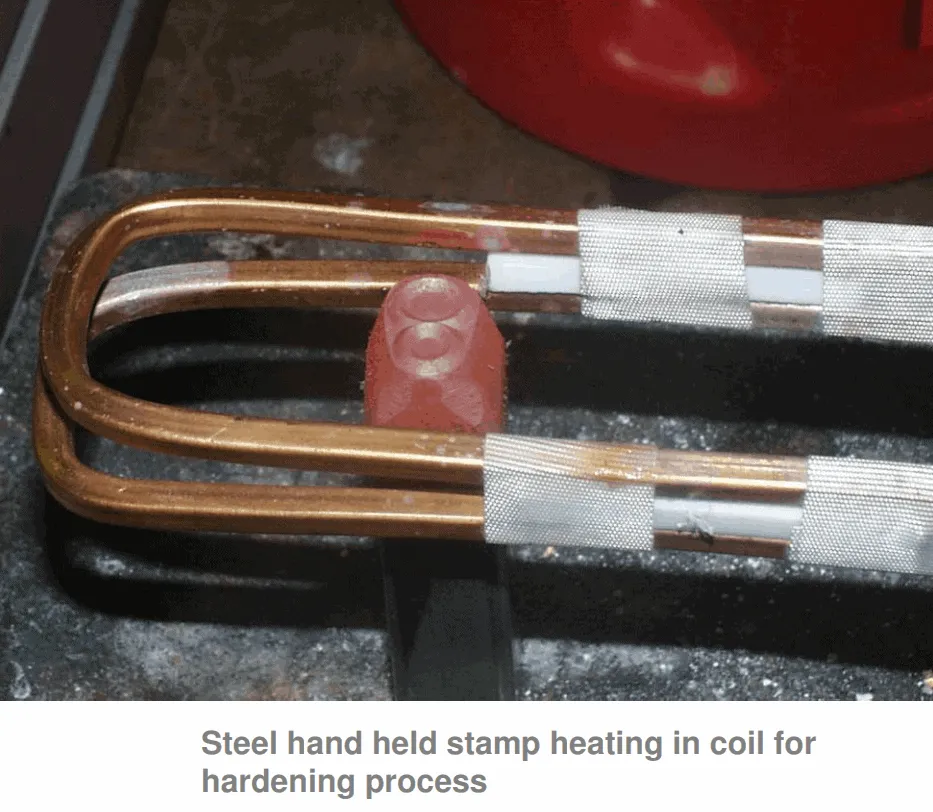

Induction Hardening and tempering Surface Process Induction Hardening Induction Hardening is a process of heating followed by cooling generally fast for increase hardness and mechanical strength of steel. To this end, the steel is heated to a temperature slightly higher than the upper critical (between 850-900ºC) and then cooled more or less quickly (depending on … Read more