The Essential Guide to Induction Hardening and Tempering Steel Rod Wires

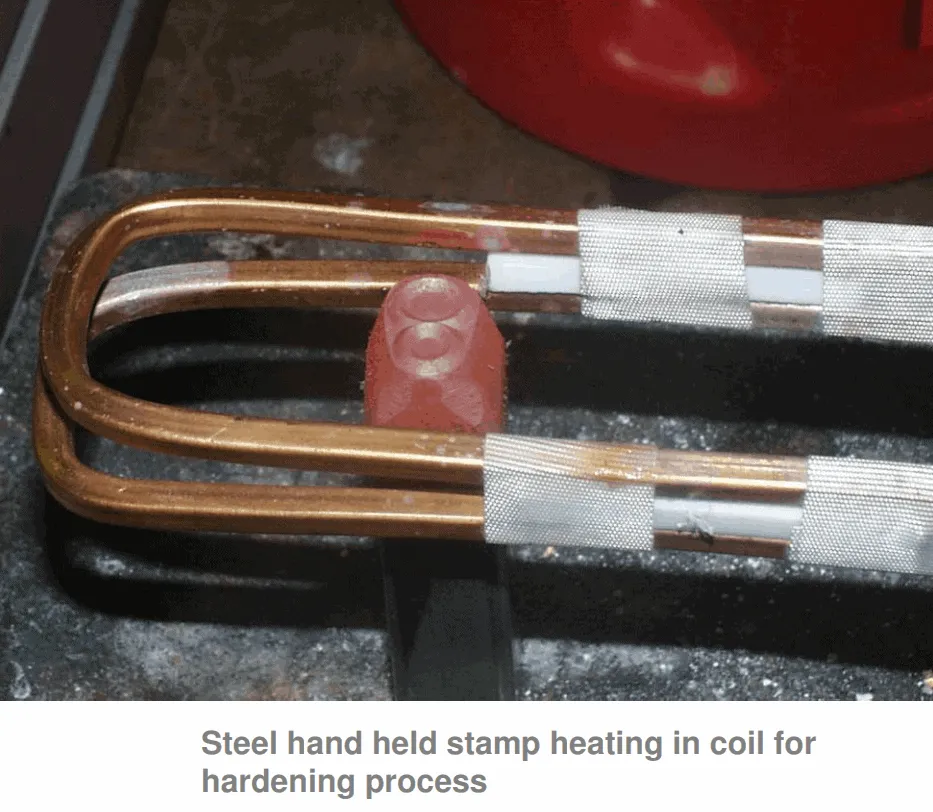

Introduction to Induction Hardening and Tempering What is Induction Hardening? Induction hardening is a heat treatment process used to selectively harden the surface of steel components, such as rod wires, while maintaining a tough and ductile core. This process involves heating the surface of the steel using high-frequency alternating current (AC) and then rapidly quenching … Read more