Portable Post Weld Heating Treatment System With Induction

Main Application:

l Preheat: weld heat,coating, spraying, bending, fitting&unfitting heat

l Post-weld heat treatment: tank, boile, pipeline, steel sheet or other metal jobs

l InductionHeat: mold heating, shipboard, zinc bath, large& irregular metal parts

l Pipeline material heat: pipeline oil, pipeline gas, pipeline water, pipeline petrochemical and other pipeline material

Main Features:

* High speed: 70%

* Low tolerance

* Energy Saving

* High efficiency

* Accurate heating

* Simple operation

* Non-contact heating

* Environmental protection

* Hypothermia circumstance

* Air cooling is suitable for low-temperature environment

* Induction heating is more uniform than oil,gas,flame heating

| MYD-20KW | MYD-10KW | |

| Input voltage | 3*380V, 50/60Hz, 4 Wires | |

| Input Current | 1~30A | 1~15A |

| Output Current | 0~300A | 0~200A |

| Output Power | 1~20KW | 1~10KW, Max 15KW, 150% duty cycle |

| Output Frequency | 5~30KHZ | |

| Thermocouple | K type | |

| Temperature system | Build in induction machine | |

| Heating Temperature | Max800℃ | Max500℃ |

| Size | 700 x 330 x 410 mm | 650 x 310 x 410 mm |

| Weight | 32kg | 26 kg |

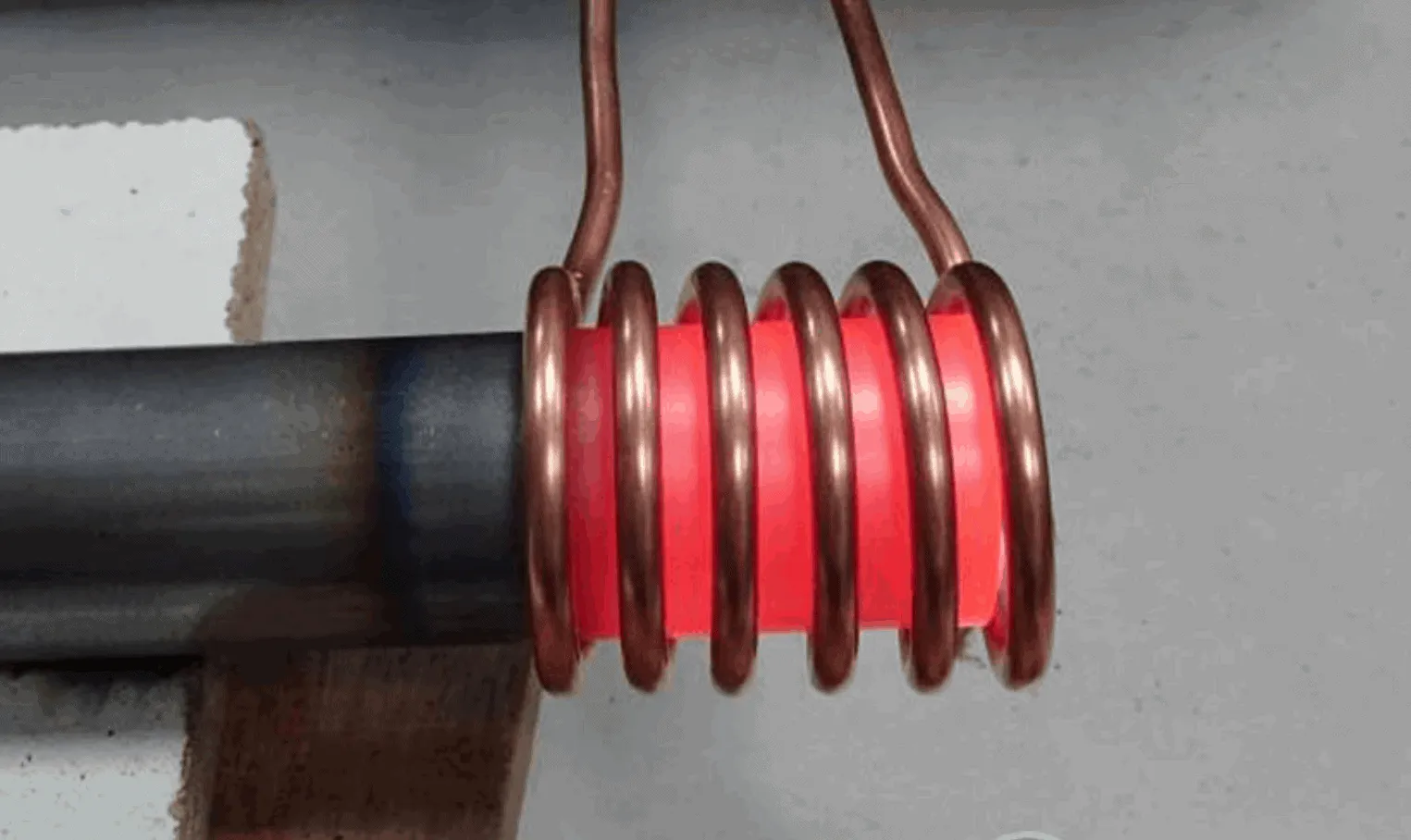

| Induction Heating coil | ||

| Length | 10~20 M | |

| Diameter | 15 mm | |

| Working temperature | -30~45℃ | |

| Pipeline Size | OD: 50~500mm or equivalent | |