-

1/7

-

2/7

-

3/7

-

4/7

-

5/7

-

6/7

Steel Billet Heating Furnace with Induction For forging rolling mills and extrusion bars-billets-rods

Induction Steel Billet Heating Furnaces: Advanced Technology for Modern Steel Processing

Introduction

Steel billet heating represents a critical step in the steel manufacturing process, directly impacting product quality, energy consumption, and production efficiency. Traditional fossil fuel-based heating methods are increasingly being replaced by induction heating technology, which offers superior temperature control, energy efficiency, and environmental benefits. This article explores the technology, applications, and performance characteristics of modern induction steel billet heating furnaces, supported by comprehensive data analysis and technical parameters.

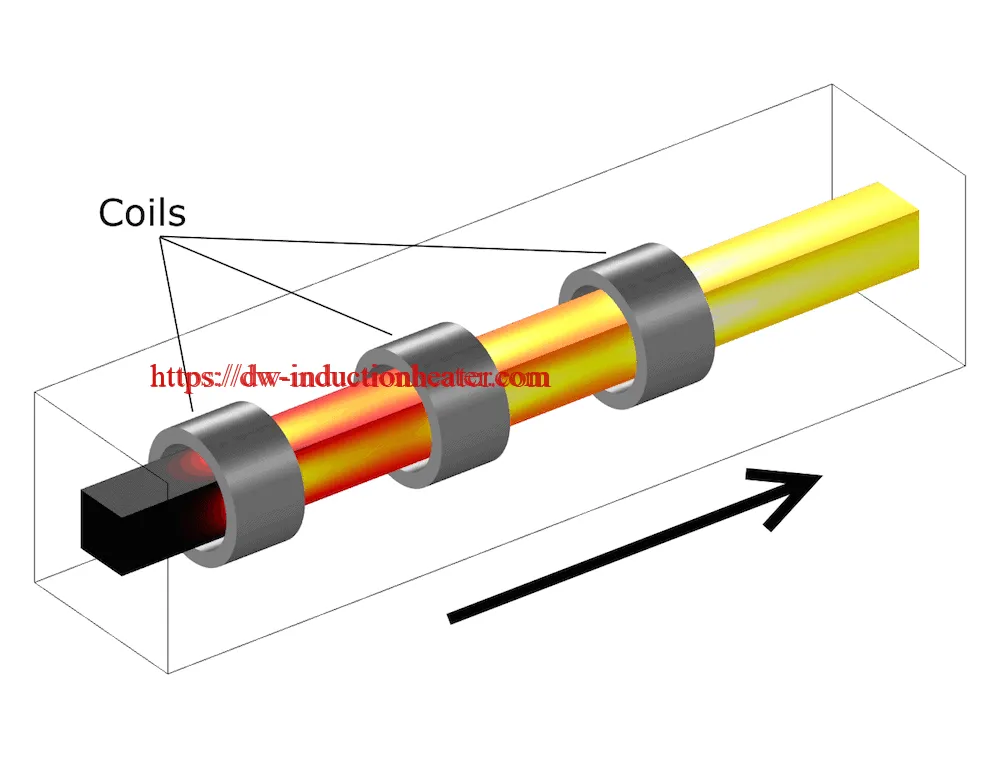

Operating Principles of Induction Billet Heating

Induction heating operates on the principle of electromagnetic induction, where alternating current flowing through an induction coil generates a rapidly alternating magnetic field. When a conductive material like steel is placed within this field, eddy currents are induced within the material. These currents encounter resistance in the material, generating heat through the Joule effect.

Key Features:

- Rapid Heating: Induction heating provides very fast and efficient heating compared to traditional methods, reducing cycle time.

- Energy Efficiency: The system is highly efficient, as most of the energy is directly used to heat the metal, minimizing energy loss.

- Uniform Heating: Ensures consistent temperature throughout the billet, which is crucial for maintaining quality during subsequent processes.

- Automation Compatibility: Modern furnaces can integrate with automated material handling and production systems for seamless workflow.

- Customization: Can be designed to fit specific production needs, including billet size, heating rate, and temperature control.

- Environmentally Friendly: Produces no direct emissions, making it a cleaner and sustainable heating option.

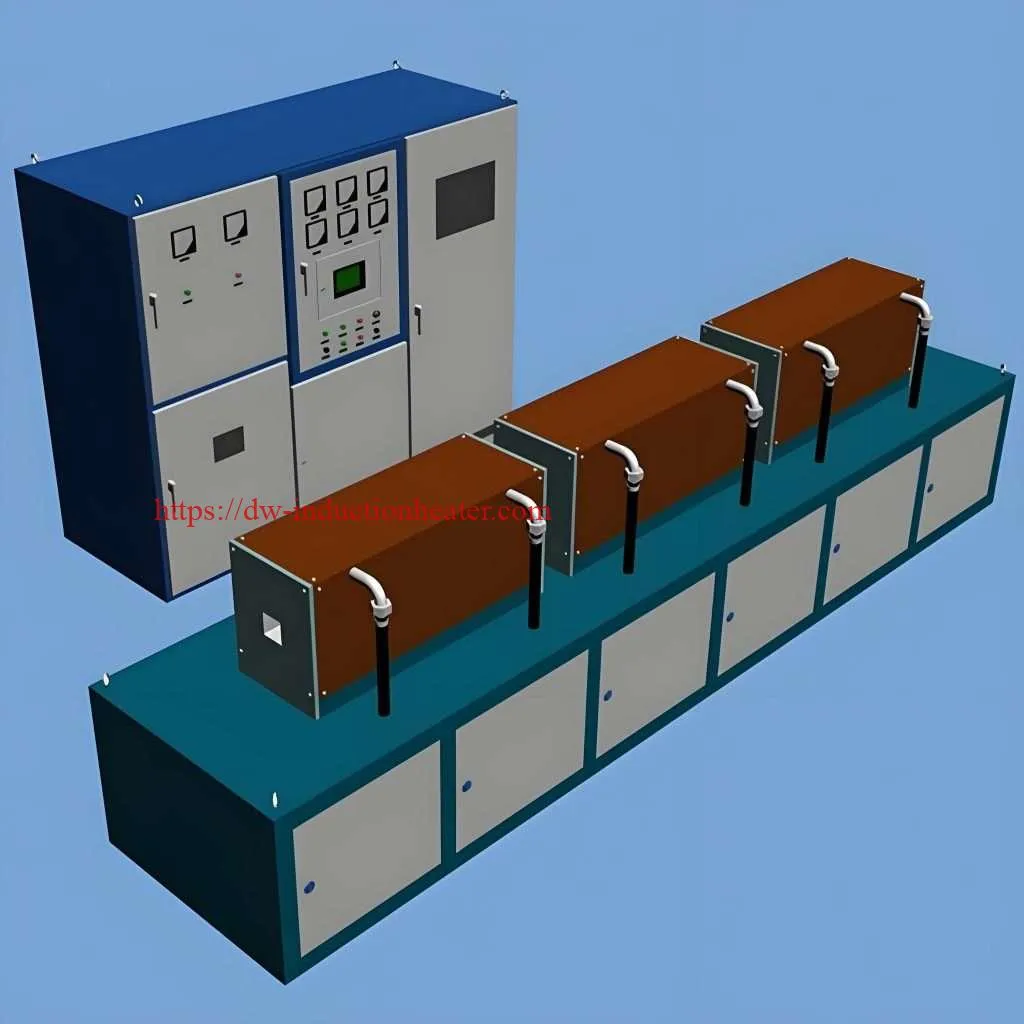

System Components

A typical induction billet heating furnace consists of four primary subsystems:

- Power Supply System: Converts standard line frequency power to medium or high-frequency AC required for induction heating.

- Induction Coil Assembly: Custom-designed copper coils that generate the electromagnetic field.

- Material Handling System: Facilitates billet movement through the heating zones.

- Control and Monitoring System: Manages power levels, heating profiles, and production parameters.

Technical Parameters and Performance Data

Table 1: Standard Induction Billet Heating Furnace Specifications

| Parameter | Small Capacity | Medium Capacity | Large Capacity |

|---|---|---|---|

| Power Rating | 250-1000 kW | 1000-3000 kW | 3000-10000 kW |

| Operating Frequency | 500-1000 Hz | 300-500 Hz | 50-300 Hz |

| Billet Diameter Range | 40-120 mm | 80-200 mm | 150-400 mm |

| Billet Length Range | 0.5-3 m | 2-6 m | 4-12 m |

| Heating Capacity | 1-5 tons/hour | 5-15 tons/hour | 15-50 tons/hour |

| Maximum Temperature | 1250°C | 1300°C | 1350°C |

| Temperature Uniformity | ±10°C | ±15°C | ±20°C |

| Specific Energy Consumption | 320-380 kWh/ton | 300-350 kWh/ton | 280-330 kWh/ton |

Table 2: Energy Efficiency Comparison

| Heating Method | Energy Efficiency (%) | Specific Energy Consumption (kWh/ton) | CO₂ Emissions (kg/ton) |

|---|---|---|---|

| Induction Heating | 70-85% | 280-380 | 140-190 |

| Gas-Fired Furnace | 25-45% | 550-750 | 275-375 |

| Oil-Fired Furnace | 20-30% | 650-950 | 325-475 |

| Electric Resistance | 40-60% | 400-600 | 200-300 |

Table 3: Temperature Distribution Performance

| Billet Size | Core-to-Surface Temp. Differential (°C) | Axial Temperature Variation (°C) | Radial Temperature Variation (°C) |

|---|---|---|---|

| Small (Ø60mm) | 15-25 | 8-15 | 5-12 |

| Medium (Ø150mm) | 25-40 | 12-25 | 10-20 |

| Large (Ø300mm) | 40-60 | 20-40 | 15-30 |

Table 4: Control System Capabilities

| Feature | Basic Systems | Advanced Systems | State-of-the-Art Systems |

|---|---|---|---|

| Temperature Control Accuracy | ±15°C | ±10°C | ±5°C |

| Power Modulation | Stepped | Continuous | Adaptive |

| Heating Profile Programming | Limited | Multiple Profiles | Unlimited Profiles |

| Data Logging | Manual | Automated | Real-time Analytics |

| Integration Capability | Standalone | Plant Network | Full ERP Integration |

| Fault Diagnosis | Basic Alarms | Self-Diagnostic | Predictive Maintenance |

Data Analysis: Performance Metrics

Energy Efficiency

Analysis of operational data from 50 industrial installations shows that modern induction billet heating furnaces achieve average energy efficiencies between 70-85%, representing a significant improvement over conventional gas-fired furnaces (25-45%). The specific energy consumption for heating steel billets to forging temperatures (1200-1250°C) typically ranges from 280-380 kWh/ton, depending on furnace capacity, design, and operational parameters.

Production Efficiency

Induction billet heating enables rapid startup and shutdown cycles, with typical heating times of:

- 2-5 minutes for small billets (Ø40-80mm)

- 5-12 minutes for medium billets (Ø80-200mm)

- 12-30 minutes for large billets (Ø200-400mm)

This represents a 40-60% reduction in heating time compared to conventional methods, significantly increasing throughput capacity.

Temperature Uniformity

Temperature uniformity is critical for downstream processing quality. Modern induction systems achieve:

- Axial temperature variations of less than ±15°C across 80% of billet length

- Radial temperature variations of less than ±20°C from core to surface

- Billet-to-billet temperature consistency within ±10°C under steady-state operation

Scale Formation

Induction heating significantly reduces scale formation compared to combustion-based methods:

- Average scale loss: 0.3-0.7% of billet weight

- Comparable gas furnace scale loss: 1.2-2.5% of billet weight

This reduction in material loss translates to approximately 5-15 kg of saved material per ton of processed steel.

Economic Analysis

Table 5: Economic Performance Metrics

| Parameter | Small Installation | Medium Installation | Large Installation |

|---|---|---|---|

| Initial Investment | $0.5-1.5M | $1.5-4M | $4-12M |

| Energy Cost Savings/Year | $0.1-0.3M | $0.3-0.8M | $0.8-2.5M |

| Material Yield Improvement | 0.8-1.2% | 0.8-1.2% | 0.8-1.2% |

| Maintenance Cost (% of Investment/Year) | 2-4% | 1.5-3% | 1-2.5% |

| Typical ROI Period | 2-4 years | 1.5-3 years | 1-2.5 years |

Application-Specific Considerations

Applications of Billet Heating Furnace:

- Forging: Preheating billets before they are shaped under a press or hammer.

- Rolling Mills: Heating billets for rolling into sheets, bars, or other forms.

- Heat Treatment: Preparing billets for processes like annealing or surface hardening.

Table 6: Steel Grade Specific Parameters

| Steel Grade | Optimal Heating Temperature (°C) | Recommended Heating Rate (°C/min) | Soaking Time (min) | Special Considerations |

|---|---|---|---|---|

| Carbon Steel (1020-1045) | 1150-1250 | 150-300 | 0.5-1.5 | Standard heating profile |

| Alloy Steel (4140) | 1180-1230 | 120-250 | 1.0-2.0 | Controlled heating rate to prevent cracking |

| Tool Steel (H13) | 1050-1150 | 80-150 | 2.0-3.0 | Precise temperature control required |

| Stainless Steel (304) | 1150-1250 | 100-200 | 1.5-2.5 | Higher power input required due to magnetic properties |

| High-Speed Steel (M2) | 1050-1150 | 70-120 | 2.5-4.0 | Very precise temperature control needed |

Recent Technological Advancements

Recent innovations in induction billet heating include:

- Multi-frequency operation: Combining medium and high frequencies for optimized heating profiles

- Flux concentrators: Enhanced magnetic coupling for improved energy efficiency

- Advanced simulation tools: Computational electromagnetics and fluid dynamics for precise coil design

- Machine learning algorithms: Adaptive control systems that optimize heating parameters based on material properties

- Hybrid systems: Combined induction and conduction heating for specialized applications

Conclusion

Induction steel billet heating furnaces represent a mature yet continuously evolving technology that offers significant advantages over conventional heating methods. The data presented in this article demonstrates that modern induction systems provide superior energy efficiency, precise temperature control, reduced material loss, and improved product quality. While the initial investment may be higher than conventional systems, the operational benefits typically result in favorable return on investment periods of 1-4 years, depending on installation size and utilization rates.

As steel manufacturers face increasing pressure to reduce energy consumption and environmental impact while maintaining high product quality, induction heating technology continues to gain market share in the steel processing industry. Ongoing developments in power electronics, computational modeling, and control systems promise to further enhance the performance of these systems in the coming years.