-

1/5

-

2/5

-

3/5

-

4/5

-

5/5

Full Automatic Induction Forging Rod Furnace

Categories: Induction Forge Furnace, Induction Forging Furnace

Tags: forging bars furnace, forging billets furnace, forging rod furnace, forging rod heater, induction billets heater, induction forge billets, induction forging, induction forging machine, induction forging rod, induction forging system

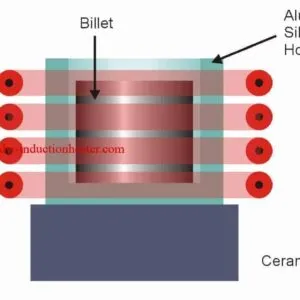

Induction Forging Rod Bar Furnace With Full Automatic Feeder System

Main parts:

- M.F Induction Heating Generator (power supply).

- Compensation Capacitor unit.

- Heating coil and accessories

- Full-auto Feeder System

- Stand or working table.

| Model | DW-MF-45KW | DW-MF-70KW | DW-MF-90KW | DW-MF-110KW | DW-MF-160KW |

| Applications | Rod about φ15-30mm |

Rod about φ15-50mm | Rod about φ15-80mm | Rod about φ15-80mm | |

| Input power max | 45KW | 70KW | 90KW | 110KW | 160KW |

| Output power max | 45KVA | 70KVA | 90KVA | 110KVA | 160KVA |

| Input Voltage desire | 3phases, 380V±10% 50 or 60HZ | ||||

| Oscillate frequency | 1KHz-20KHz,according to the application ,normal about 4KHZ、8KHZ、11KHZ、15KHZ、20KHZ | ||||

| Duty cycle | 100%,24hours work | ||||

Main characteristics:

- Suitable for rod heating of steel,cooper,bronze and aluminum.

- Portable and light weight, easily installed beside any pressing equipment.

- Installation and operation can be very easily to use.

- The rod can be rapidly heated to forging temperature to reduce the oxidation of the rod furnace and to raise the quality of the parts.

- With a very large range of frequency adaptable the rod larger than 15mm can be heated.more rapidly and more evenly.

- Designed to work continuously everyday.

- Pneumatic rod feeding.

- High efficiency,saving energy and cost.

- Easy to change heating coil to heat rods of different size.

- No preheating required just start the machine and can heat the components to a temperature of 1350 Degree Centigrade.

- Full auto feeder system for rod bars.

Related products

-

Steel Billet Heating Furnace with Induction For forging rolling mills and extrusion bars-billets-rods

-

Induction Bar Heating Systems for Metal Forging Rolling and Extrusion Applications

-

Induction Billet Heating Furnace For Rolling Mills and Extrusion Metals Billets Bars rods

-

Induction Forging Billets