-

1/8

-

2/8

-

3/8

-

4/8

-

5/8

-

6/8

-

7/8

-

8/8

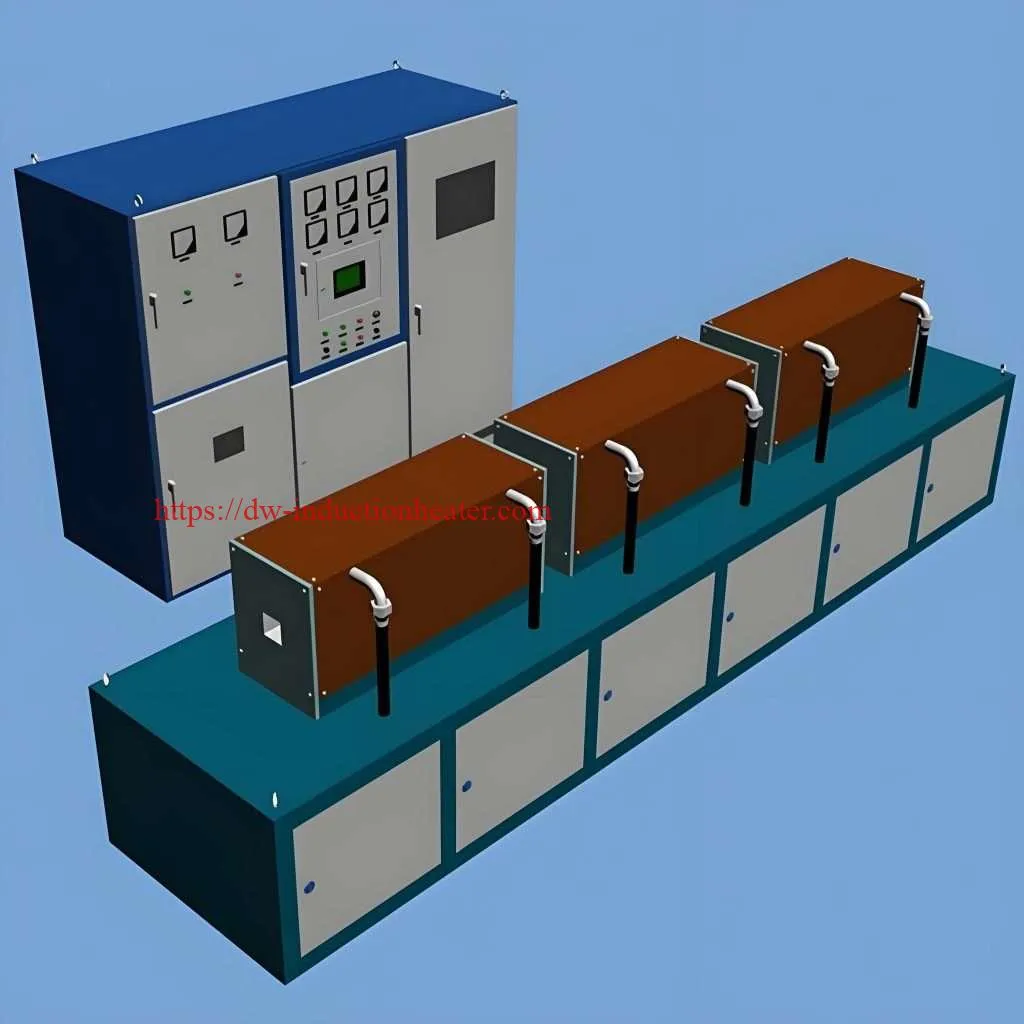

Billet Heating Furnace With Induction

Continous Billet Heating Furnace with induction for the heating of copper/aluminum/iron steel billets before hot forming

Product Description

For heating various of bar materials: such as steel & iron, bronze, brass, aluminum alloy, etc.

Picture just for reference, color is changable with different power.

Functions and special specifications customized by customer’s requirements.

Features and Advantages:

1.Automatic:Automatic feeding, automatic selection of the work-piece is good or bad, automatic measurement of temperature, automatic discharge.

2. Integrated design: Save installation time,cost and space.

3. Operation panel embedded displays machine operating states, to facilitate fault diagnosis.

| Features | Detail | |

| 1 | Heating fast and stable | saving 20%- 30% electric energy than traditional way;

High efficiency and low energy consumption |

| 2 | Small in size | Easy to install, operate and repair |

| 3 | Safe and reliable | No high voltage, very safe to your workers. |

| 4 | A cooling circulation system | Able to operate continuously 24 hours |

| 5 | complete self-protect function |

many types of alarm lamps: over-current, over-voltage, over hot, water shortage etc. These lamps can control and protect machine. |

| 6 | Environmental protection | Almost no oxide layer, produced no exhaust, no waste-water |

| 7 | IGBT Type | Avoid the interruption of unrelated electric net; Ensure the long-life of the machine. |

Parameter of billet heating furnace:

| DW-MF-200 | DW-MF-250 | DW-MF-300 | DW-MF-400 | DW-MF-500 | DW-MF-600 | ||

| Input Voltage | 3phases, 380V/410V/440V , 50/60Hz | ||||||

| Max Input Current | 320A | 400A | 480A | 640A | 800A | 960A | |

| Oscillating frequency | 0.5KHz^20KHz ( Oscillating frequency will be customized according to the size of heating parts) | ||||||

| Duty Cycle Loading | 100%,24h continuously work | ||||||

| Cooling Water Desires | 0.1MPa<Water Pressure<0.3MPa, Water hardness<50 | ||||||

| Dimension | Host | 1000X800X1500mm | 1500X800X2800mm | 850X1700X1900mm | |||

| Extension | extension will be customized according to the material and size of heating parts | ||||||

| Weight | 110kg | 150kg | 160kg | 170kg | 200kg | 220kg | |

| Depend on the dimension of extension | |||||||

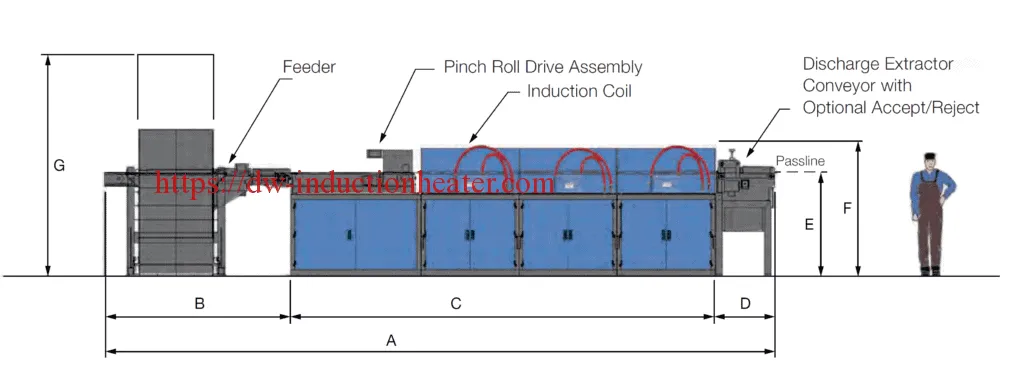

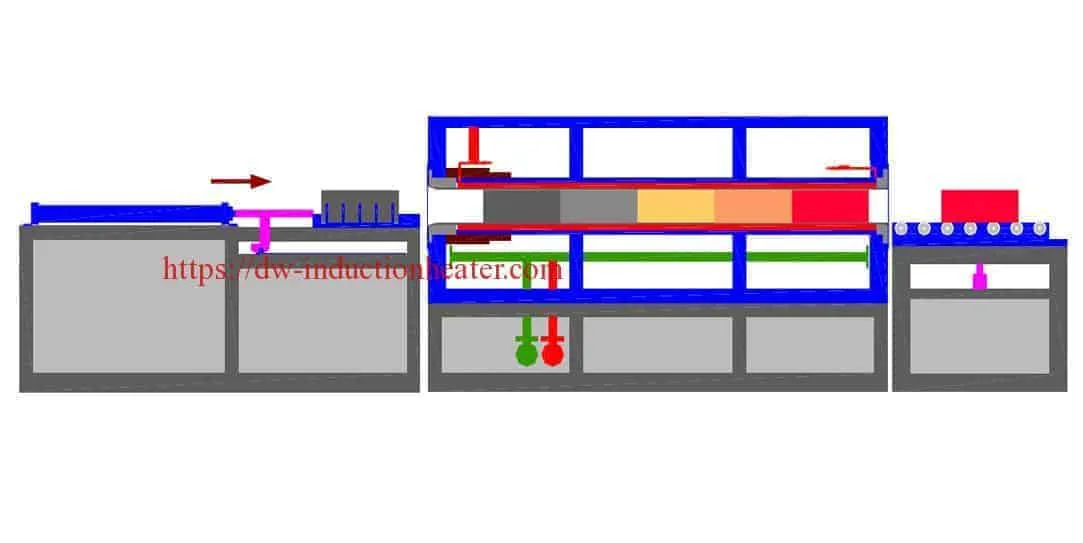

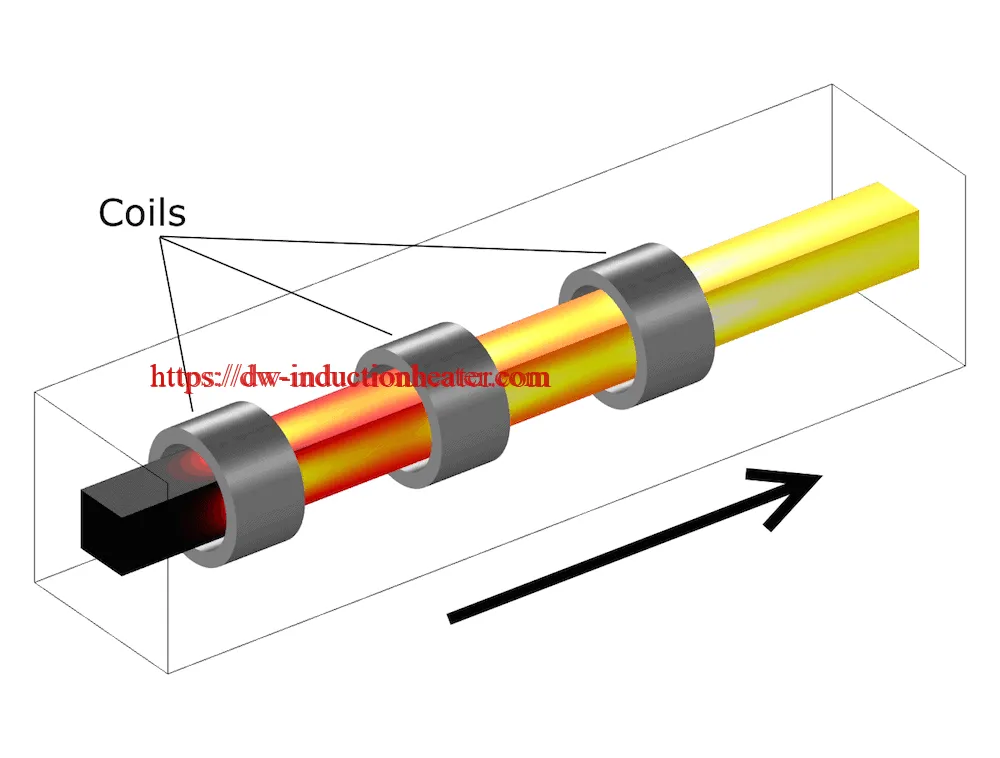

In the induction billet heating furnace the whole of the billets or slug is heated. Normally for short billets or slugs a hopper or bowl is used to automatically present the billets in line to pinch rollers, chain driven tractor units or in some cases pneumatic pushers. The billets are then driven through the coil one behind the other on water cooled rails or ceramic liners are used through the coil bore which reduce friction and prevent wear. The length of the coil is a function of the required soak time, the cycle time per component and the length of the billet. In high volume large cross section work it is not unusual to have 4 or 5 coils in series to give 5 m (16 ft) of coil or more.

This article explores the comprehensive technical aspects of induction bar heating furnaces for various metals including steel, copper, brass, aluminum, titanium, and more. We’ll examine the fundamental principles, system components, technical parameters, operational considerations, and specific applications across different metals.

Why Induction Heating for Aluminum, Copper, and Steel Bars?

Each bar material—aluminum, copper, and steel—has distinct thermal and electrical properties, influencing its heating behavior. Here’s how induction heating stands out for each material:

- Aluminum Bars: Known for their high thermal conductivity and low density, aluminum bars require lower heating cycles. Induction heating ensures precise temperature control without overheating or warping sensitive aluminum alloys.

- Copper Bars: With exceptionally high thermal and electrical conductivity, copper heats rapidly under induction. Uniform heating prevents thermal stress and optimizes efficiency.

- Steel Bars: Steel is ideal for induction heating due to its relatively lower conductivity and magnetic properties. Induction furnaces handle steel heating impeccably for processes like surface hardening and forging.

Fundamental Principles of Induction Heating

Induction heating operates on the principles of electromagnetic induction and Joule heating.

- Electromagnetic Field: A high-frequency alternating current (AC) flows through a specifically designed induction coil (inductor).

- Induced Currents: This current generates a strong, rapidly alternating magnetic field around and within the coil. When a conductive metal bar is placed inside this field, the changing magnetic flux induces circulating electrical currents within the bar, known as eddy currents.

- Joule Heating: Due to the electrical resistance of the metal bar, these eddy currents dissipate energy in the form of heat (I²R losses, where I is current and R is resistance).

- Hysteresis Heating (for Magnetic Materials): For ferromagnetic materials like steel below their Curie temperature (approx. 770°C), additional heat is generated by hysteresis losses as the magnetic domains within the material resist the rapid reversals of the magnetic field.

The key parameters affecting induction heating include:

- Frequency: Determines the penetration depth of heating

- Power density: Controls the heating rate

- Material properties: Electrical resistivity and magnetic permeability

- Coupling distance: Gap between inductor and workpiece

- Residence time: Duration of exposure to the induction field

Core Components of an Induction Bar Heating System

A typical induction bar heating furnace consists of the following components:

- Power supply: Converts standard line frequency (50/60 Hz) to medium or high frequencies (500 Hz to 400 kHz)

- Induction coil: Creates the electromagnetic field to heat the workpiece

- Material handling system: Feeds bars through the heating zone

- Cooling system: Maintains operational temperatures of components

- Control system: Monitors and regulates heating parameters

- Temperature measurement devices: Pyrometers or thermocouples for feedback control

- Protective atmosphere system: For sensitive materials like titanium

Technical Parameters for Different Metal Applications

Steel Bar Heating Parameters

| Parameter | Low Carbon Steel | Medium Carbon Steel | High Carbon Steel | Alloy Steel |

|---|---|---|---|---|

| Optimal Forging Temp (°C) | 1150-1250 | 1100-1200 | 1050-1150 | 1050-1200 |

| Heating Rate (°C/min) | 300-600 | 250-500 | 200-400 | 200-450 |

| Power Density (kW/kg) | 1.0-1.8 | 0.9-1.6 | 0.8-1.4 | 0.8-1.5 |

| Frequency Range (kHz) | 0.5-10 | 0.5-10 | 1-10 | 1-10 |

| Typical Efficiency (%) | 70-85 | 70-85 | 65-80 | 65-80 |

| Atmosphere Requirements | Air/Nitrogen | Air/Nitrogen | Controlled atmosphere | Controlled atmosphere |

Non-Ferrous Metal Bar Heating Parameters

| Parameter | Copper | Brass | Aluminum | Titanium |

|---|---|---|---|---|

| Optimal Forging Temp (°C) | 750-900 | 650-850 | 400-500 | 900-950 |

| Heating Rate (°C/min) | 150-300 | 180-350 | 250-450 | 100-200 |

| Power Density (kW/kg) | 0.6-1.2 | 0.5-1.0 | 0.4-0.8 | 0.7-1.2 |

| Frequency Range (kHz) | 2-10 | 2-10 | 3-15 | 3-15 |

| Typical Efficiency (%) | 55-70 | 60-75 | 65-80 | 60-75 |

| Atmosphere Requirements | Inert/Reducing | Inert/Reducing | Air/Nitrogen | Argon/Vacuum |

System Configuration Parameters by Bar Diameter

| Bar Diameter (mm) | Recommended Frequency (kHz) | Typical Power Range (kW) | Maximum Throughput (kg/hr) | Temperature Uniformity (±°C) |

|---|---|---|---|---|

| 10-25 | 8-15 | 50-200 | 100-500 | 5-10 |

| 25-50 | 4-8 | 150-400 | 300-1000 | 8-15 |

| 50-100 | 1-4 | 300-800 | 800-2500 | 10-20 |

| 100-200 | 0.5-2 | 600-1500 | 1500-5000 | 15-25 |

| >200 | 0.3-1 | 1000-3000 | 3000-10000 | 20-30 |

Thermal Efficiency Analysis

Induction heating offers significant efficiency advantages compared to conventional heating methods:

| Heating Method | Thermal Efficiency (%) | Energy Consumption (kWh/ton) | CO₂ Emissions (kg/ton) |

|---|---|---|---|

| Induction Heating | 70-90 | 350-450 | 175-225 |

| Gas-Fired Furnace | 20-45 | 800-1100 | 400-550 |

| Oil-Fired Furnace | 20-40 | 850-1200 | 600-850 |

| Electric Resistance | 45-70 | 500-650 | 250-325 |

Material-Specific Considerations and Applications

Steel Bar Heating Furnaces

Steel’s magnetic properties (until reaching Curie temperature) make it ideal for induction heating, resulting in high efficiency.

Table : Technical Specifications for Steel Bar Induction Furnaces

| Parameter | Small Capacity | Medium Capacity | Large Capacity |

|---|---|---|---|

| Power Rating (kW) | 100-300 | 350-800 | 900-3000 |

| Frequency Range (kHz) | 1-5 | 0.5-3 | 0.2-1 |

| Max. Bar Diameter (mm) | 25-80 | 80-150 | 150-300 |

| Heating Capacity (kg/h) | 200-600 | 600-1500 | 1500-5000 |

| Temperature Range (°C) | 500-1250 | 500-1250 | 500-1250 |

| Energy Consumption (kWh/t) | 280-340 | 250-310 | 230-290 |

Table : Performance Data for Steel Bar Heating

| Bar Diameter (mm) | Heating Time to 1200°C (min) | Power Consumption (kWh) | Temperature Uniformity (±°C) |

|---|---|---|---|

| 30 | 2-3 | 15-22 | ±8 |

| 60 | 4-7 | 40-55 | ±10 |

| 120 | 8-12 | 100-140 | ±15 |

| 250 | 15-22 | 300-380 | ±20 |

Steel remains the most common material heated in induction furnaces. The Curie point (approximately 760°C) significantly impacts the heating process, as magnetic properties change above this temperature.

For steel bars, induction heating provides:

- Consistent through-heating for homogeneous microstructure

- Minimal scale formation (0.3-0.8% material loss vs. 2-3% in conventional furnaces)

- Precise temperature control for critical alloys

Application Example: Automotive crankshaft production requires heating 60mm diameter alloy steel bars to 1180°C with ±10°C uniformity. Modern induction systems achieve this with 450kW power input at 3kHz frequency, processing 1,200 kg/hr with 78% efficiency.

Copper Bar Heating Furnaces

Copper’s excellent electrical conductivity makes it challenging for induction heating, requiring specialized equipment.

Table : Technical Specifications for Copper Bar Induction Furnaces

| Parameter | Small Capacity | Medium Capacity | Large Capacity |

|---|---|---|---|

| Power Rating (kW) | 75-200 | 250-600 | 700-2000 |

| Frequency Range (kHz) | 3-10 | 2-6 | 1-4 |

| Max. Bar Diameter (mm) | 15-50 | 50-100 | 100-200 |

| Heating Capacity (kg/h) | 150-400 | 400-1000 | 1000-3500 |

| Temperature Range (°C) | 400-1000 | 400-1000 | 400-1000 |

| Energy Consumption (kWh/t) | 290-350 | 260-320 | 240-300 |

Table : Performance Data for Copper Bar Heating

| Bar Diameter (mm) | Heating Time to 800°C (min) | Power Consumption (kWh) | Temperature Uniformity (±°C) |

|---|---|---|---|

| 20 | 2-4 | 12-18 | ±4 |

| 40 | 4-8 | 30-40 | ±6 |

| 80 | 9-14 | 80-110 | ±9 |

| 150 | 18-25 | 200-260 | ±12 |

Copper’s high thermal conductivity presents challenges for uniform heating. Higher frequencies (3-10 kHz) are typically employed to optimize the skin effect and ensure even heat distribution.

Technical Parameters for Copper Bar Extrusion:

- Optimal heating temperature: 750-850°C

- Power density: 0.8-1.0 kW/kg

- Heating time for 50mm bar: 2-3 minutes

- Frequency selection: 4-8 kHz

- Atmosphere: Nitrogen or reducing atmosphere to prevent oxidation

Aluminum Bar Heating Furnaces

Aluminum’s high thermal conductivity and low electrical resistivity present unique challenges for induction heating.

Table : Technical Specifications for Aluminum Bar Induction Furnaces

| Parameter | Small Capacity | Medium Capacity | Large Capacity |

|---|---|---|---|

| Power Rating (kW) | 50-150 | 200-500 | 600-1500 |

| Frequency Range (kHz) | 2-8 | 1-4 | 0.5-3 |

| Max. Bar Diameter (mm) | 20-60 | 60-120 | 120-250 |

| Heating Capacity (kg/h) | 100-300 | 300-800 | 800-3000 |

| Temperature Range (°C) | 300-650 | 300-650 | 300-650 |

| Energy Consumption (kWh/t) | 320-380 | 280-340 | 260-310 |

Table : Performance Data for Aluminum Bar Heating

| Bar Diameter (mm) | Heating Time to 550°C (min) | Power Consumption (kWh) | Temperature Uniformity (±°C) |

|---|---|---|---|

| 25 | 3-5 | 15-20 | ±5 |

| 50 | 6-10 | 35-45 | ±7 |

| 100 | 12-18 | 90-120 | ±10 |

| 200 | 25-35 | 250-320 | ±15 |

Aluminum’s high electrical conductivity and low melting point require careful control:

Critical Parameters for Aluminum Billet Heating:

- Precise temperature control (±5°C) to avoid partial melting

- Higher frequencies (5-15 kHz) to overcome high conductivity

- Typical power density: 0.4-0.7 kW/kg

- Temperature ramp rate control: 250-400°C/min

- Automated ejection systems to prevent overheating

Titanium Processing

Titanium’s reactivity with oxygen necessitates protective atmospheres:

Specialized Requirements for Titanium Heating:

- Argon gas protection or vacuum environments

- Temperature uniformity within ±8°C

- Typical operating temperatures: 900-950°C

- Moderate power densities: 0.7-1.0 kW/kg

- Enhanced monitoring systems to prevent hot spots

Advanced System Design and Control Features

Power Supply Technology

Modern induction bar heating systems employ solid-state power supplies with the following specifications:

| Power Supply Type | Frequency Range | Power Factor | Efficiency | Control Accuracy |

|---|---|---|---|---|

| IGBT Inverter | 0.5-10 kHz | >0.95 | 92-97% | ±1% |

| MOSFET Inverter | 5-400 kHz | >0.93 | 90-95% | ±1% |

| SCR Converter | 0.05-3 kHz | >0.90 | 85-92% | ±2% |

Temperature Control Systems

| Control Method | Accuracy | Response Time | Application |

|---|---|---|---|

| Optical Pyrometry | ±5°C | 10-50ms | Surface temperature |

| Multipoint Thermocouples | ±3°C | 100-500ms | Profile monitoring |

| Thermal Imaging | ±7°C | 30-100ms | Full-surface analysis |

| Mathematical Modeling | ±10°C | Real-time | Core temperature estimation |

Energy Consumption Analysis

The following data represents typical energy consumption patterns for bar heating applications:

| Metal Type | Bar Diameter (mm) | Energy Required (kWh/ton) | CO₂ Reduction vs. Gas (%) |

|---|---|---|---|

| Carbon Steel | 50 | 380-420 | 55-65 |

| Stainless Steel | 50 | 400-450 | 50-60 |

| Copper | 50 | 200-250 | 60-70 |

| Aluminum | 50 | 160-200 | 65-75 |

| Titanium | 50 | 450-500 | 45-55 |

Case Study: Optimized Induction System for Multi-Metal Processing

A modern induction bar heating system designed for flexible production demonstrates the versatility of current technology:

System Specifications:

- Power capacity: 800 kW

- Frequency range: 0.5-10 kHz (automatically adjusted)

- Bar diameter range: 30-120 mm

- Maximum throughput: 3,000 kg/hr (steel)

- Temperature range: 400-1300°C

- Atmosphere control: Adjustable from oxidizing to inert

- Energy recovery system: 15-20% power recuperation

Performance Data by Material:

| Material | Bar Size (mm) | Throughput (kg/hr) | Energy Consumption (kWh/ton) | Temperature Uniformity (±°C) |

|---|---|---|---|---|

| Carbon Steel | 80 | 2,800 | 390 | 12 |

| Alloy Steel | 80 | 2,600 | 410 | 14 |

| Stainless Steel | 80 | 2,400 | 430 | 15 |

| Copper | 80 | 3,200 | 220 | 8 |

| Brass | 80 | 3,000 | 210 | 10 |

| Aluminum | 80 | 2,200 | 180 | 7 |

| Titanium | 80 | 1,800 | 470 | 9 |

Future Trends and Innovations

The induction bar heating industry continues to evolve with several key technological trends:

- Digital twin technology: Real-time simulation models predicting temperature distribution throughout the bar

- AI-powered adaptive control: Self-optimizing systems that adjust parameters based on material variations

- Hybrid heating systems: Combined induction and conduction heating for optimized energy usage

- Enhanced power electronics: Wide-bandgap semiconductors (SiC, GaN) enabling higher efficiencies

- Advanced thermal insulation: Nano-ceramic materials reducing heat losses by 15-25%

Conclusion

Induction metal bar heating systems sent a sophisticated and versatile technology for metal processing applications. The ability to precisely control heating parameters, achieve excellent temperature uniformity, and significantly reduce energy consumption makes these systems ideal for high-value metal processing operations.

The selection of appropriate technical parameters—frequency, power density, heating time, and atmosphere control—must be carefully tailored to the specific material and application requirements. Modern systems offer unprecedented levels of control, efficiency, and flexibility, enabling manufacturers to process a wide range of materials with optimal results.

Induction bar heating furnaces are indispensable for heating aluminum, copper, and steel bars, offering unparalleled efficiency, uniformity, and sustainability. Whether you aim to streamline forging operations or achieve precise temperature control for heat treatment, this technology ensures optimal results across various industries. With their customizable parameters and advanced capabilities, induction furnaces are shaping the future of metal heating processes.