-

1/6

-

2/6

-

3/6

-

4/6

-

5/6

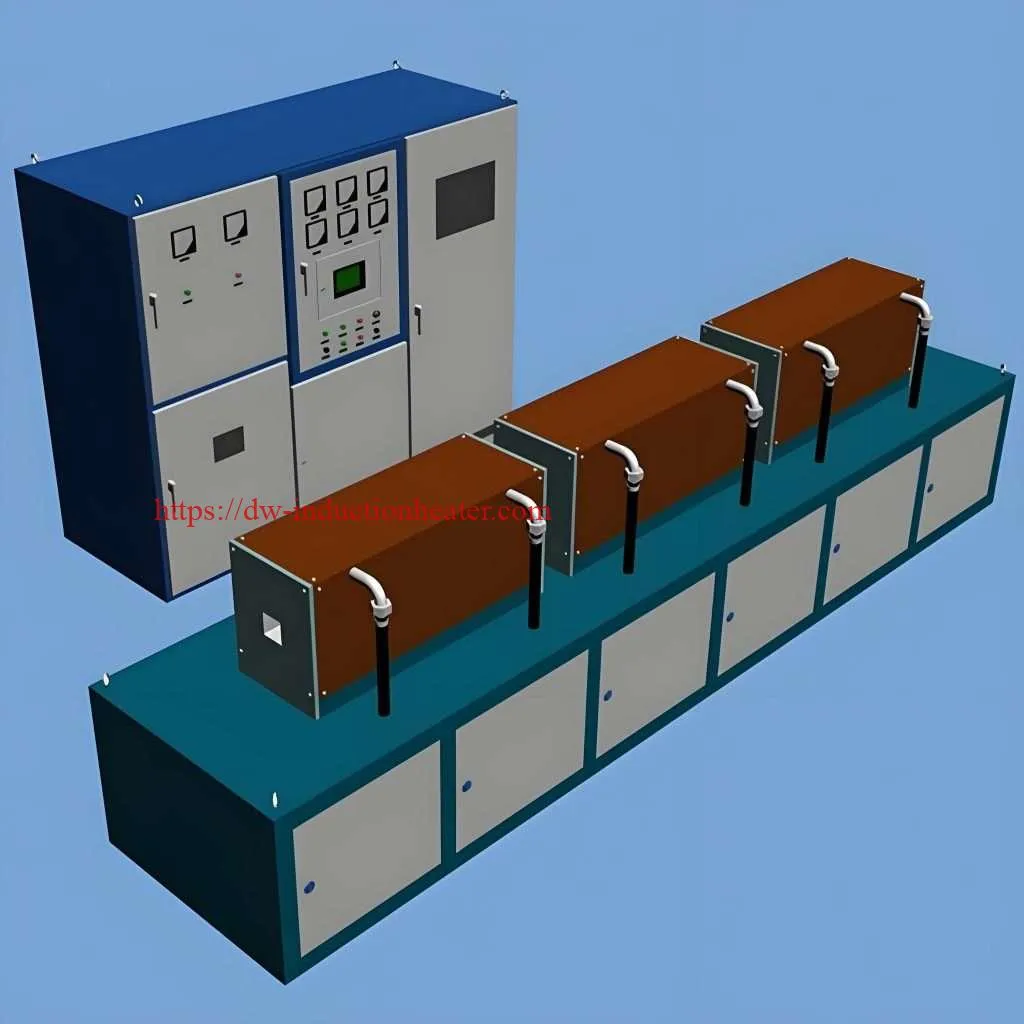

Induction Bar Heating Furnaces For Forging Rolling and Extrusion of Steel Copper Brass Aluminum Titanium and More

Induction Bar Heating Furnaces for Metal Forging, Rolling, and Extrusion Applications

Induction bar heating furnaces represent a pinnacle of modern metallurgical technology, offering precise, efficient, and environmentally friendly solutions for heating various metal bars and billets before forging, rolling, and extrusion processes. Unlike conventional fuel-fired furnaces, induction heating systems utilize electromagnetic principles to generate heat directly within the workpiece, resulting in faster heating rates, reduced energy consumption, and superior temperature uniformity.

This article explores the comprehensive technical aspects of induction bar heating furnaces for various metals including steel, copper, brass, aluminum, titanium, and more. We’ll examine the fundamental principles, system components, technical parameters, operational considerations, and specific applications across different metals.

Fundamental Principles of Induction Heating

Induction heating operates on the principles of electromagnetic induction and Joule heating.

- Electromagnetic Field: A high-frequency alternating current (AC) flows through a specifically designed induction coil (inductor).

- Induced Currents: This current generates a strong, rapidly alternating magnetic field around and within the coil. When a conductive metal bar is placed inside this field, the changing magnetic flux induces circulating electrical currents within the bar, known as eddy currents.

- Joule Heating: Due to the electrical resistance of the metal bar, these eddy currents dissipate energy in the form of heat (I²R losses, where I is current and R is resistance).

- Hysteresis Heating (for Magnetic Materials): For ferromagnetic materials like steel below their Curie temperature (approx. 770°C), additional heat is generated by hysteresis losses as the magnetic domains within the material resist the rapid reversals of the magnetic field.

The key parameters affecting induction heating include:

- Frequency: Determines the penetration depth of heating

- Power density: Controls the heating rate

- Material properties: Electrical resistivity and magnetic permeability

- Coupling distance: Gap between inductor and workpiece

- Residence time: Duration of exposure to the induction field

Core Components of an Induction Bar Heating System

A typical induction bar heating furnace consists of the following components:

- Power supply: Converts standard line frequency (50/60 Hz) to medium or high frequencies (500 Hz to 400 kHz)

- Induction coil: Creates the electromagnetic field to heat the workpiece

- Material handling system: Feeds bars through the heating zone

- Cooling system: Maintains operational temperatures of components

- Control system: Monitors and regulates heating parameters

- Temperature measurement devices: Pyrometers or thermocouples for feedback control

- Protective atmosphere system: For sensitive materials like titanium

Technical Parameters for Different Metal Applications

Steel Bar Heating Parameters

| Parameter | Low Carbon Steel | Medium Carbon Steel | High Carbon Steel | Alloy Steel |

|---|---|---|---|---|

| Optimal Forging Temp (°C) | 1150-1250 | 1100-1200 | 1050-1150 | 1050-1200 |

| Heating Rate (°C/min) | 300-600 | 250-500 | 200-400 | 200-450 |

| Power Density (kW/kg) | 1.0-1.8 | 0.9-1.6 | 0.8-1.4 | 0.8-1.5 |

| Frequency Range (kHz) | 0.5-10 | 0.5-10 | 1-10 | 1-10 |

| Typical Efficiency (%) | 70-85 | 70-85 | 65-80 | 65-80 |

| Atmosphere Requirements | Air/Nitrogen | Air/Nitrogen | Controlled atmosphere | Controlled atmosphere |

Non-Ferrous Metal Bar Heating Parameters

| Parameter | Copper | Brass | Aluminum | Titanium |

|---|---|---|---|---|

| Optimal Forging Temp (°C) | 750-900 | 650-850 | 400-500 | 900-950 |

| Heating Rate (°C/min) | 150-300 | 180-350 | 250-450 | 100-200 |

| Power Density (kW/kg) | 0.6-1.2 | 0.5-1.0 | 0.4-0.8 | 0.7-1.2 |

| Frequency Range (kHz) | 2-10 | 2-10 | 3-15 | 3-15 |

| Typical Efficiency (%) | 55-70 | 60-75 | 65-80 | 60-75 |

| Atmosphere Requirements | Inert/Reducing | Inert/Reducing | Air/Nitrogen | Argon/Vacuum |

System Configuration Parameters by Bar Diameter

| Bar Diameter (mm) | Recommended Frequency (kHz) | Typical Power Range (kW) | Maximum Throughput (kg/hr) | Temperature Uniformity (±°C) |

|---|---|---|---|---|

| 10-25 | 8-15 | 50-200 | 100-500 | 5-10 |

| 25-50 | 4-8 | 150-400 | 300-1000 | 8-15 |

| 50-100 | 1-4 | 300-800 | 800-2500 | 10-20 |

| 100-200 | 0.5-2 | 600-1500 | 1500-5000 | 15-25 |

| >200 | 0.3-1 | 1000-3000 | 3000-10000 | 20-30 |

Thermal Efficiency Analysis

Induction heating offers significant efficiency advantages compared to conventional heating methods:

| Heating Method | Thermal Efficiency (%) | Energy Consumption (kWh/ton) | CO₂ Emissions (kg/ton) |

|---|---|---|---|

| Induction Heating | 70-90 | 350-450 | 175-225 |

| Gas-Fired Furnace | 20-45 | 800-1100 | 400-550 |

| Oil-Fired Furnace | 20-40 | 850-1200 | 600-850 |

| Electric Resistance | 45-70 | 500-650 | 250-325 |

Material-Specific Considerations and Applications

Steel Processing

Steel remains the most common material heated in induction furnaces. The Curie point (approximately 760°C) significantly impacts the heating process, as magnetic properties change above this temperature.

For steel bars, induction heating provides:

- Consistent through-heating for homogeneous microstructure

- Minimal scale formation (0.3-0.8% material loss vs. 2-3% in conventional furnaces)

- Precise temperature control for critical alloys

Application Example: Automotive crankshaft production requires heating 60mm diameter alloy steel bars to 1180°C with ±10°C uniformity. Modern induction systems achieve this with 450kW power input at 3kHz frequency, processing 1,200 kg/hr with 78% efficiency.

Copper and Brass Processing

Copper’s high thermal conductivity presents challenges for uniform heating. Higher frequencies (3-10 kHz) are typically employed to optimize the skin effect and ensure even heat distribution.

Technical Parameters for Copper Bar Extrusion:

- Optimal heating temperature: 750-850°C

- Power density: 0.8-1.0 kW/kg

- Heating time for 50mm bar: 2-3 minutes

- Frequency selection: 4-8 kHz

- Atmosphere: Nitrogen or reducing atmosphere to prevent oxidation

Aluminum Processing

Aluminum’s high electrical conductivity and low melting point require careful control:

Critical Parameters for Aluminum Billet Heating:

- Precise temperature control (±5°C) to avoid partial melting

- Higher frequencies (5-15 kHz) to overcome high conductivity

- Typical power density: 0.4-0.7 kW/kg

- Temperature ramp rate control: 250-400°C/min

- Automated ejection systems to prevent overheating

Titanium Processing

Titanium’s reactivity with oxygen necessitates protective atmospheres:

Specialized Requirements for Titanium Heating:

- Argon gas protection or vacuum environments

- Temperature uniformity within ±8°C

- Typical operating temperatures: 900-950°C

- Moderate power densities: 0.7-1.0 kW/kg

- Enhanced monitoring systems to prevent hot spots

Advanced System Design and Control Features

Power Supply Technology

Modern induction bar heating systems employ solid-state power supplies with the following specifications:

| Power Supply Type | Frequency Range | Power Factor | Efficiency | Control Accuracy |

|---|---|---|---|---|

| IGBT Inverter | 0.5-10 kHz | >0.95 | 92-97% | ±1% |

| MOSFET Inverter | 5-400 kHz | >0.93 | 90-95% | ±1% |

| SCR Converter | 0.05-3 kHz | >0.90 | 85-92% | ±2% |

Temperature Control Systems

| Control Method | Accuracy | Response Time | Application |

|---|---|---|---|

| Optical Pyrometry | ±5°C | 10-50ms | Surface temperature |

| Multipoint Thermocouples | ±3°C | 100-500ms | Profile monitoring |

| Thermal Imaging | ±7°C | 30-100ms | Full-surface analysis |

| Mathematical Modeling | ±10°C | Real-time | Core temperature estimation |

Energy Consumption Analysis

The following data represents typical energy consumption patterns for bar heating applications:

| Metal Type | Bar Diameter (mm) | Energy Required (kWh/ton) | CO₂ Reduction vs. Gas (%) |

|---|---|---|---|

| Carbon Steel | 50 | 380-420 | 55-65 |

| Stainless Steel | 50 | 400-450 | 50-60 |

| Copper | 50 | 200-250 | 60-70 |

| Aluminum | 50 | 160-200 | 65-75 |

| Titanium | 50 | 450-500 | 45-55 |

Case Study: Optimized Induction System for Multi-Metal Processing

A modern induction bar heating system designed for flexible production demonstrates the versatility of current technology:

System Specifications:

- Power capacity: 800 kW

- Frequency range: 0.5-10 kHz (automatically adjusted)

- Bar diameter range: 30-120 mm

- Maximum throughput: 3,000 kg/hr (steel)

- Temperature range: 400-1300°C

- Atmosphere control: Adjustable from oxidizing to inert

- Energy recovery system: 15-20% power recuperation

Performance Data by Material:

| Material | Bar Size (mm) | Throughput (kg/hr) | Energy Consumption (kWh/ton) | Temperature Uniformity (±°C) |

|---|---|---|---|---|

| Carbon Steel | 80 | 2,800 | 390 | 12 |

| Alloy Steel | 80 | 2,600 | 410 | 14 |

| Stainless Steel | 80 | 2,400 | 430 | 15 |

| Copper | 80 | 3,200 | 220 | 8 |

| Brass | 80 | 3,000 | 210 | 10 |

| Aluminum | 80 | 2,200 | 180 | 7 |

| Titanium | 80 | 1,800 | 470 | 9 |

Future Trends and Innovations

The induction bar heating industry continues to evolve with several key technological trends:

- Digital twin technology: Real-time simulation models predicting temperature distribution throughout the bar

- AI-powered adaptive control: Self-optimizing systems that adjust parameters based on material variations

- Hybrid heating systems: Combined induction and conduction heating for optimized energy usage

- Enhanced power electronics: Wide-bandgap semiconductors (SiC, GaN) enabling higher efficiencies

- Advanced thermal insulation: Nano-ceramic materials reducing heat losses by 15-25%

Conclusion

Induction bar heating furnaces represent a sophisticated and versatile technology for metal processing applications. The ability to precisely control heating parameters, achieve excellent temperature uniformity, and significantly reduce energy consumption makes these systems ideal for high-value metal processing operations.

The selection of appropriate technical parameters—frequency, power density, heating time, and atmosphere control—must be carefully tailored to the specific material and application requirements. Modern systems offer unprecedented levels of control, efficiency, and flexibility, enabling manufacturers to process a wide range of materials with optimal results.

As environmental regulations tighten and energy costs continue to rise, induction heating technology will likely see further adoption across the metal forming industry, particularly for high-value materials and precision applications where quality and consistency are paramount.