-

1/7

-

2/7

-

3/7

-

4/7

-

5/7

-

6/7

-

7/7

Induction Forging End of Bar and Rod for Copper and Iron Steel

Description

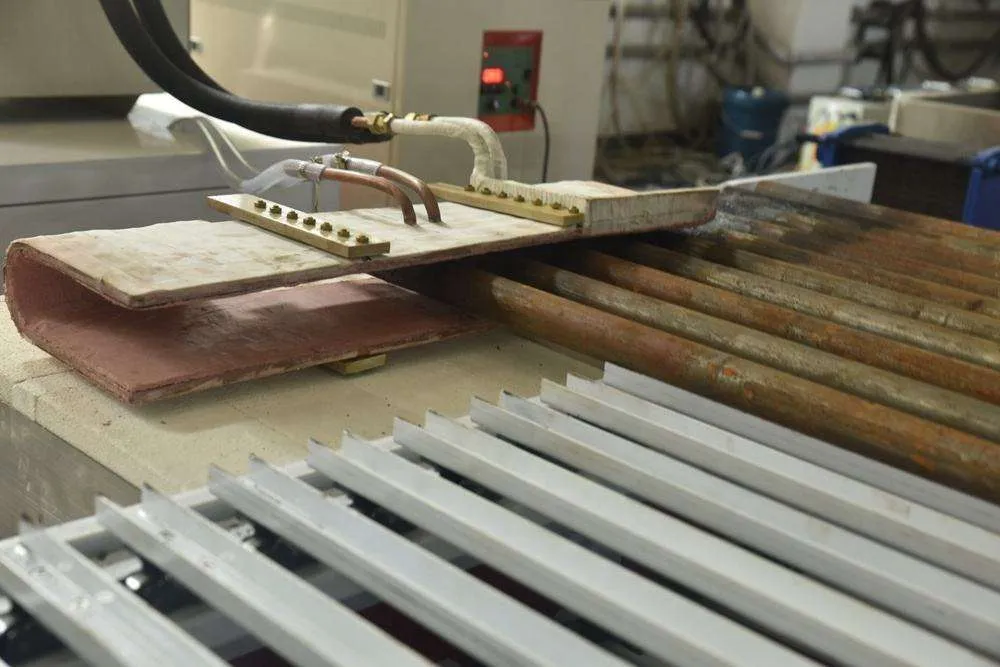

Induction Forging End of Bar and Rod for Copper ,Aluminum and Iron Steel

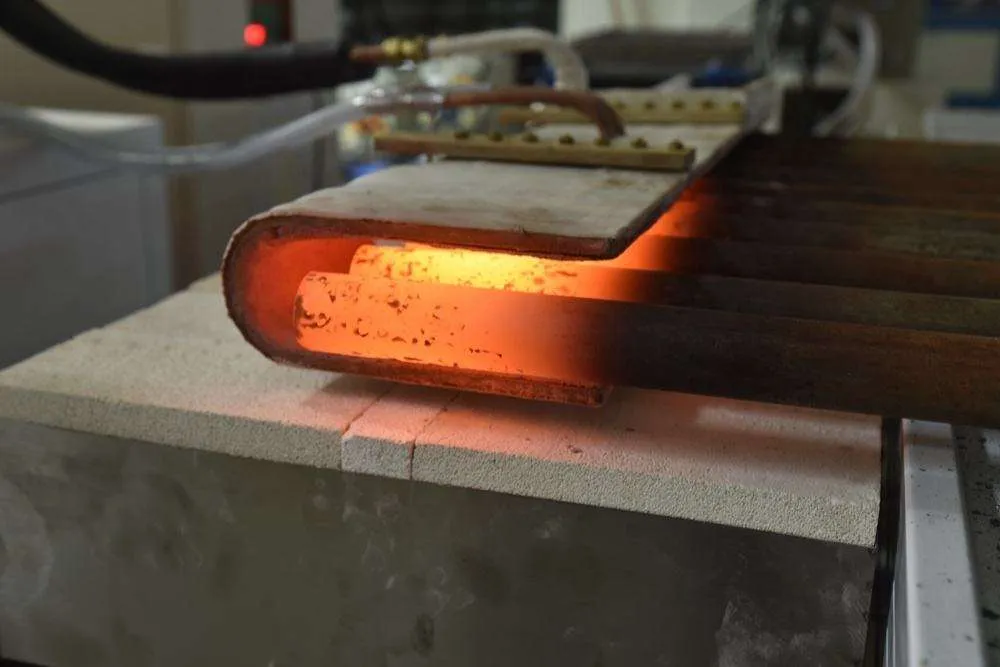

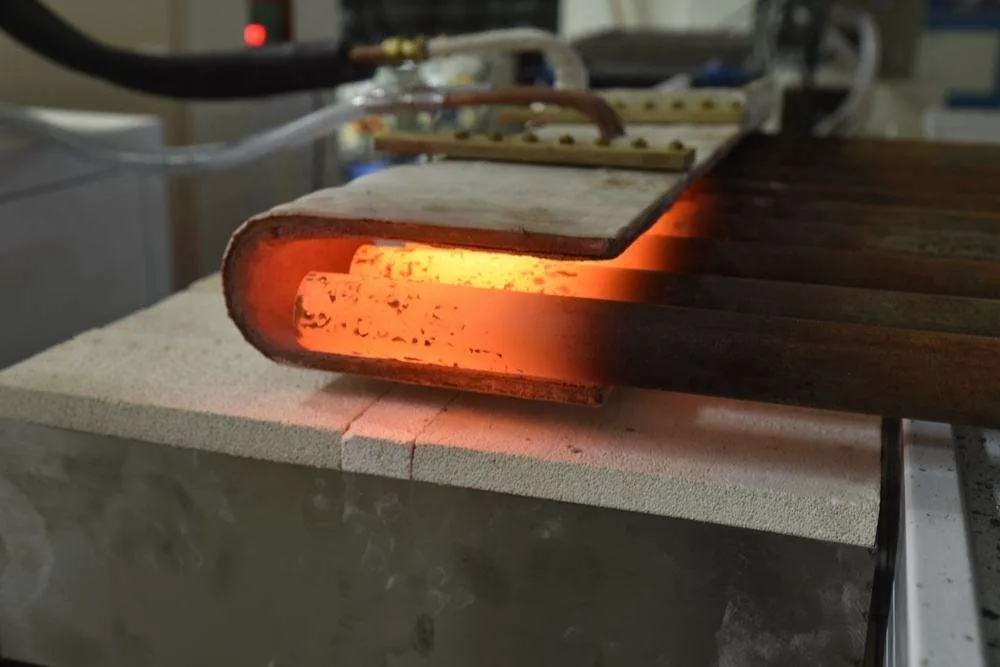

Induction forging: refers to the use of an induction heater to pre-heat metals prior to deformation using a press or hammer. Typically metals are heated to between 1,100 °C (2,010 °F) and 1,200 °C (2,190 °F) to increase their malleability and aid flow in the forging die.

Induction forging: refers to the use of an induction heater to pre-heat metals prior to deformation using a press or hammer. Typically metals are heated to between 1,100 °C (2,010 °F) and 1,200 °C (2,190 °F) to increase their malleability and aid flow in the forging die.

Process: Induction heating is a non-contact process which uses the principle of electromagnetic induction to produce heat in a workpiece. By placing a conductive material into a strong alternating magnetic field, electrical current is made to flow in the material, thereby causing Joule heating. In magnetic materials, further heat is generated below the Curie point due to hysteresis losses. The generated current flows predominantly in the surface layer, the depth of this layer being dictated by the frequency of the alternating field and the permeability of the material.

Advantages:

■ Process controllability

■ Energy efficiency

■ Rapid temperature rise

■ Process consistency

Application: It is suitable for diathermy of copper rods, iron rods and aluminum rods of different shapes. The workpiece can be heated as a whole or locally.

Main Applications:

Induction forging end of rod furnace is used for heating of bars and rods larger than Φ12mm or square or other shape stuff in the shaping of screws, nuts, valves, locks and other metal parts, the material can be steel ,stainless steel, copper, brass, bronze, aluminum and so on, the heating can be the whole heating and partial heating , such as end heating or middle part heating.

The composing of the induction forging furnace:

The composing of the induction forging furnace:

- Induction heating power supply.

- Induction heating coil and guide rail and coil cover.

- pneumatic rod feeder.

- control system.

- water cooling system.

For some application, the infrared temperature sensor, temperature controller and automatic rod feeding systems can also be included if ordered.

Main models and heating ability:

| Models | Max input power | Recommend application | Heating ability of normal material | |

| Steel or stainless steel to 1200℃ | Copper or brass to 700℃ | |||

| MF-35 induction forging furnace | 35KW | Φ15-30 rod heating | 1.25KG/min | 1.75KG/min |

| MF-45 induction forging furnace | 45KW | 1.67KG/min | 2.33KG/min | |

| MF-70 induction forging furnace | 70KW | Φ15-50 rod heating | 2.5KG/min | 3.5KG/min |

| MF-90 induction forging furnace | 90KW | Φ25-50 rod heating | 3.33KG/min | 4.67KG/min |

| MF-110 induction forging furnace | 110KW | 4.17KG/min | 5.83KG/min | |

| MF-160 induction forging furnace | 160KW | Φ50 up rod heating | 5.83KG/min | 8.26KG/min |

Main models and heating ability:

Main models and heating ability:

| Models | Power | Recommend application | Heating capacity for Steel or stainless steel to 1200℃,KG/Hour | Heating capacity for copper to 700℃,KG/Hour | |

| SF-40AB | 40KW | Φ15-40mm rod heating | 110KG/hour | 190KG/hour | |

| SF-50AB | 50KW | Φ15-40mm rod heating | 137KG/hour | 237KG/hour | |

| SF-60AB | 60KW | Φ15-40mm rod heating | 160KG/hour | 290KG/hour | |

| SF-80AB | 80KW | Φ15-40mm rod heating | 165KG/hour | 380KG/hour | |

| SF-100AB | 100KW | Φ15-40mm rod heating | 275KG/hour | 480KG/hour | |

| SF-120AB | 120KW | Φ15-40mm rod heating | 275KG/hour | 480KG/hour | |

| SF-120AB | 120KW | Φ15-40mm rod heating | 330KG/hour | 570KG/hour | |

| SF-160AB | 160KW | Φ15-40mm rod heating | 440KG/hour | 770KG/hour | |

| SF-200AB | 200KW | Φ15-40mm rod heating | 550KG/hour | 960KG/hour | |

| SF-250AB | 250KW | Φ15-40mm rod heating | 690KG/hour | 1180KG/hour | |

| MFS-200 or D-MFS200 | 200KW | Φ40 up rod heating | 550KG/hour | 960KG/hour | |

| MFS-250 or D-MFS250 | 250KW | 690KG/hour | 1180KG/hour | ||

| MFS-300 or D-MFS300 | 300KW | 830KG/hour | 1440KG/hour | ||

| MFS-400 or D-MFS400 | 400KW | 1100KG/hour | 1880KG/hour | ||

| MFS-500 or D-MFS500 | 500KW | 1380KG/hour | 2350KG/hour | ||

| MFS-600 or D-MFS500 | 600KW | 1660 KG/hour | 2820 KG/hour | ||

| MFS-750 or D-MFS750 | 750KW | 2070 KG/hour | 3525 KG/hour | ||

| MFS-800 or D-MFS800 | 800KW | 2210KG/hour | 3700KG/hour | ||

| MFS-1000 or D-MFS1000 | 1000KW | 2750KG/hour | 4820KG/hour | ||

| MFS-1200 or D-MFS1200 | 1200KW | 3300 KG/hour | 5780KG/hour | ||

| MFS-1500 or D-MFS1500 | 1500KW | 4200KG/hour | 7200KG/hour | ||

| MFS-2000 or D-MFS2000 | 2000KW | 5500KG/hour | 9600KG/hour |