-

1/3

-

2/3

Induction Forging Steel Rod End

Induction Forging Steel Rod End With Induction Heating Machine

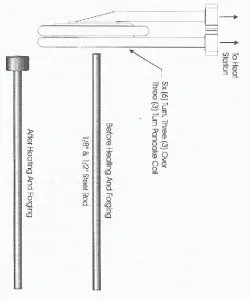

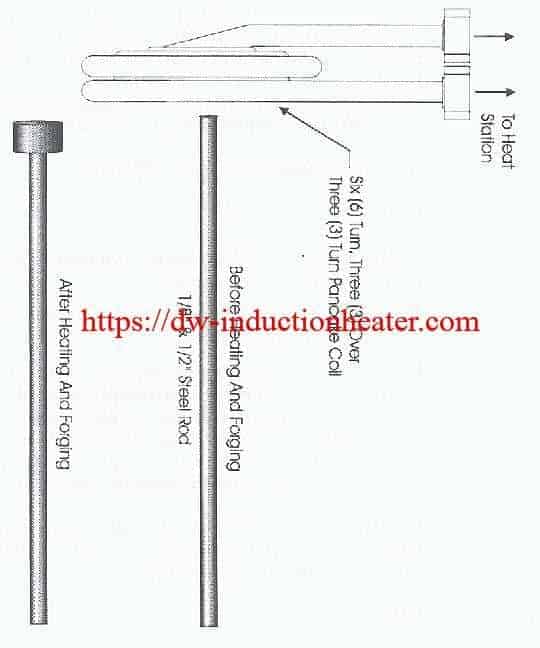

Objective To heat the ends of steel rods to 1800ºF prior to a forging operation. Processing of the rods includes heating, pressing in a two part die to forge the push rod end, and a final heating in a channel coil to temper the rods and relieve the forging stresses. The customer needs to process rods of different

diameter between 1/8″ and 1/2″. The rod temperature must be above 1400ºF in the center while the outer edge can be as high as 1900ºF.

Material Steel rods of different diameters from 1/8″ to 1/2″

Temperature 1800ºF

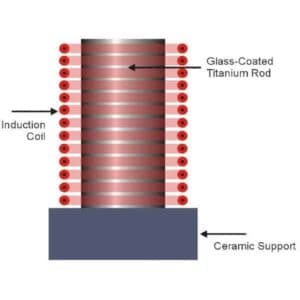

Frequency 50 kHz

Equipment DW-HF-45kW output solid state induction power supply including a remote heat station containing 2 capacitors totaling 0.5 μF, along with a 6 turn (3 over 3) helical type coil.

Process The DW-HF-45kW output solid state induction power supply was found to achieve the following results:

Results • Both diameter steel rods reached 1800ºF in less than 5 seconds as measured by an optical pyrometer.

• The 1/2″ rod was limited by the physical properties of steel with the time required to transfer the heat from the outside edge of the bar to the center to raise the temperature to 1400ºF without melting the bar surface. The 1/8″ rod heating was limited by the induction heating efficiency at 80 kHz. Larger diameter bars progressively heated faster up to the thermal conductivity restrictions.