-

1/3

-

2/3

-

3/3

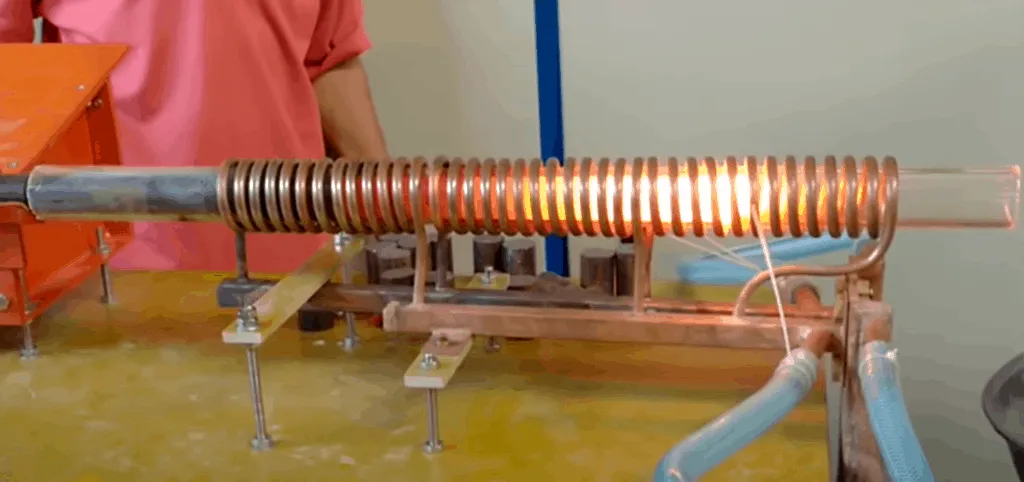

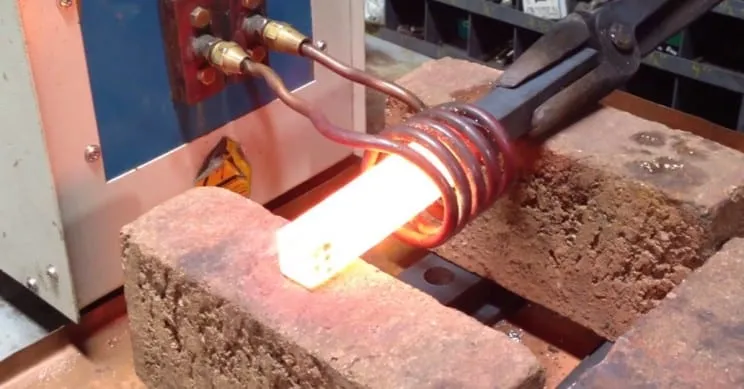

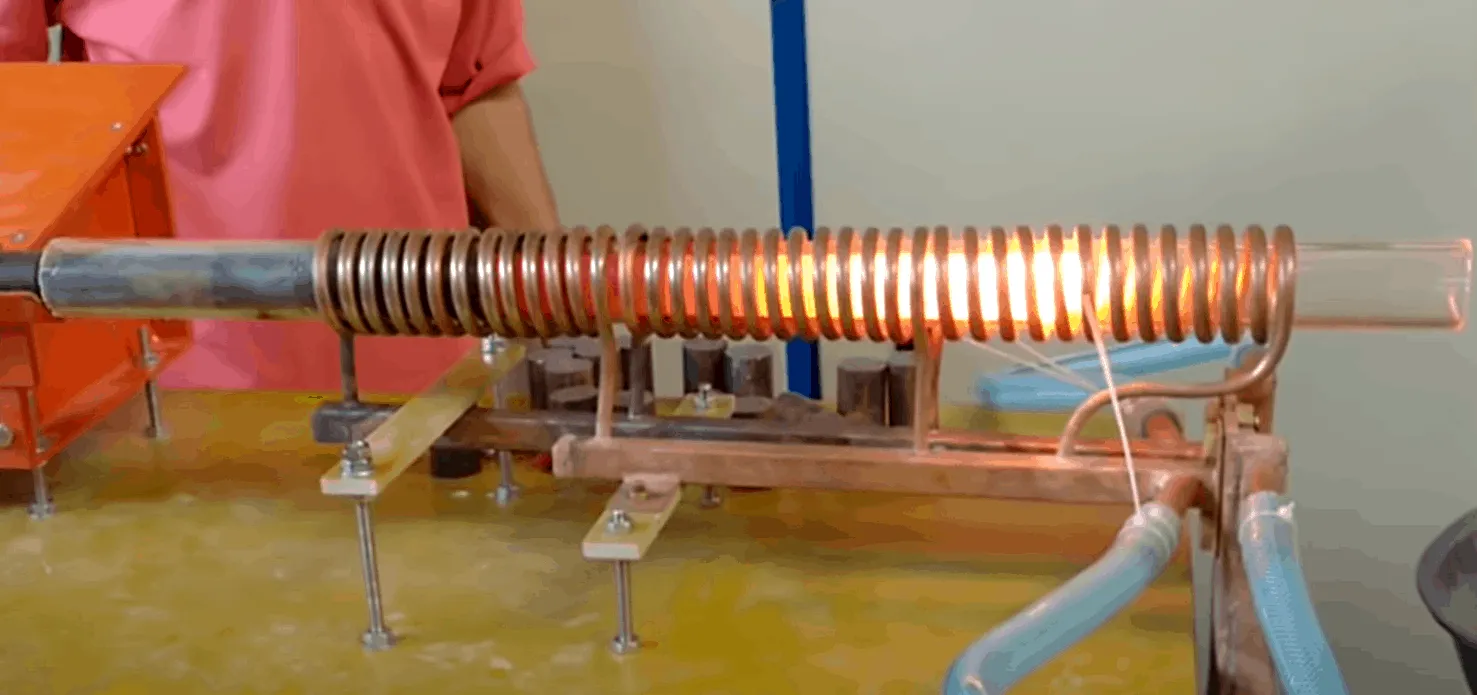

Induction Preheat Welding Steel Rods

Induction preheat welding steel rods applications

Objective To preheat steel rods to 500 ºF (260 ºC) for a welding application for a major equipment manufacturer

Material: Customer supplied steel pins (varying, on average 2”/51mm)

Temperature: 500 ºF (260 ºC)

Frequency: 100 kHz

Equipment: DW-HF-45kW 50-150 kHz induction heating system equipped with a remote heat station containing eight 1.0 μF capacitors

– A multiple position two-turn induction heating coil designed and developed specifically for this application

Induction Preheating Process: The steel rod was loaded into the coil, and the heat was turned on. The part reached 600 ºF (316 ºC) within one minute. The power was turned off and the rod was monitored for 30 seconds to ensure the outside layer did not drop below 500 ºF (260 ºC).

Based on the Application Lab’s experiences and testing, the longer the heating time, the less power is required.

Additionally, the longer the heating time, the longer the outside temperature remained above 500 ºF.

In light of that, there are additional possibilities when it comes to power supplies, from a 15kW induction heater with a two-position coil that has a heating time of two minutes, to a 45kW induction heating system with a four-position coil and a heating time of one minute.

Results/Benefits

Precise heating: The customer is looking at switching from flame, as induction can offer more precise, repeatable heating

– Penetration: Induction does a superior job penetrating the pin when compared to a torch, which is critical to

preheating for welding

– Speed: Induction enables fast heating which can boost production compared to torch heating

– Part quality: A torch can make the part brittle, which makes induction advantageous

– Work environment: Induction preheat welding is a safer heating method that introduces less heat into the workplace than a flame does