Objective

Induction Brazing carbide to steel parts

Equipment

DW-HF-15kw Induction Heating Power Supply

HLQ custom coil

Key Parameters

Power: 5.88 kW

Temperature: Approximately 1500°F (815°C)

Time: 10 sec

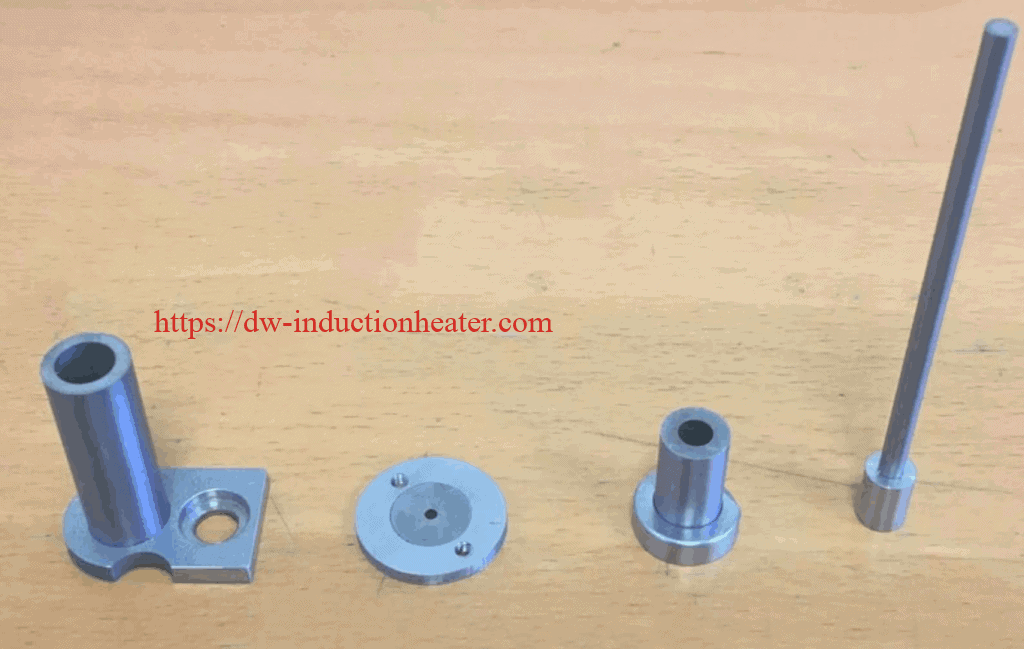

Materials

Coil-

2 helical turns (20 mm ID)

1 planar turn (40 mm OD, 13 mm Height)

Carbide-

13 mm OD, 3 mm wall thickness

Steel piece–

20 mm OD, 13 mm ID

Process:

- To demonstrate elimination of “hand feeding” the alloy, we formed the alloy into a ring to tightly fit over the center post tube. This method provides a uniform amount for each cycle, resulting in uniform joints and wetting.

- The custom made coil was then placed over the steel piece, where is was set for 10 seconds to heat the alloy.

- The alloy was heated at approximately 1500°F (815)°C

- The whole piece is left alone and cooled with ambient air

Results/Benefits:

- Induction Brazing was successful all in under 15 seconds with 8kW

- High quality and repeatability of the brazed joints

- Increased productivity

- Rings will need to be developed for specific joints to prevent the use of too much alloy

- Precise control of the time and temperature