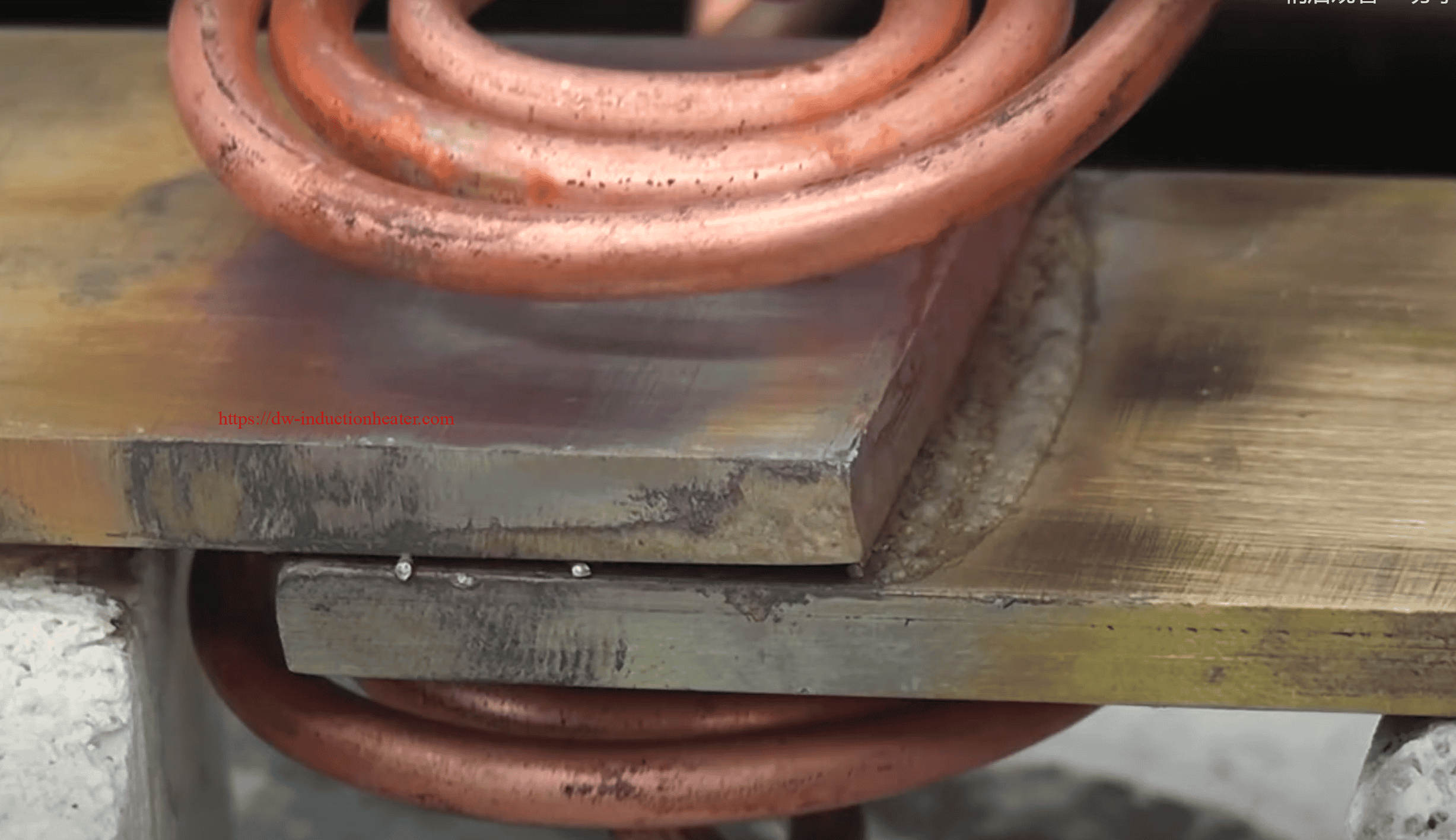

Heating Stainless Steel Reaction Vessel by Electromagnetic Induction

In the realm of industrial processing and chemical synthesis, the ability to control temperature with precision is not just beneficial, it is imperative. The heating of reaction vessels is a critical task that must be executed with both efficiency and uniformity to ensure optimal reaction conditions and product quality. Among the numerous methods available for … Read more