-

1/7

-

2/7

-

3/7

-

4/7

-

5/7

-

6/7

-

7/7

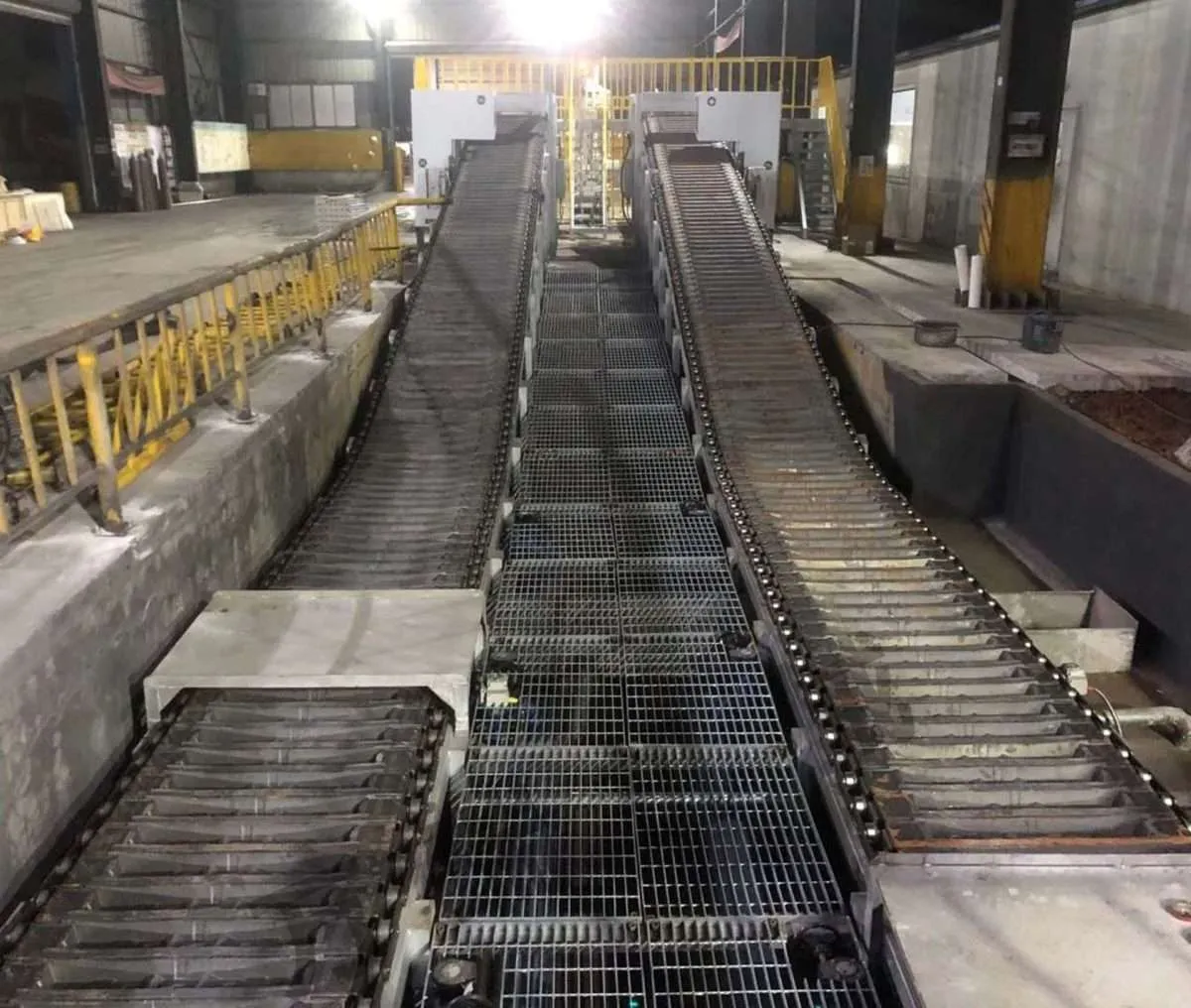

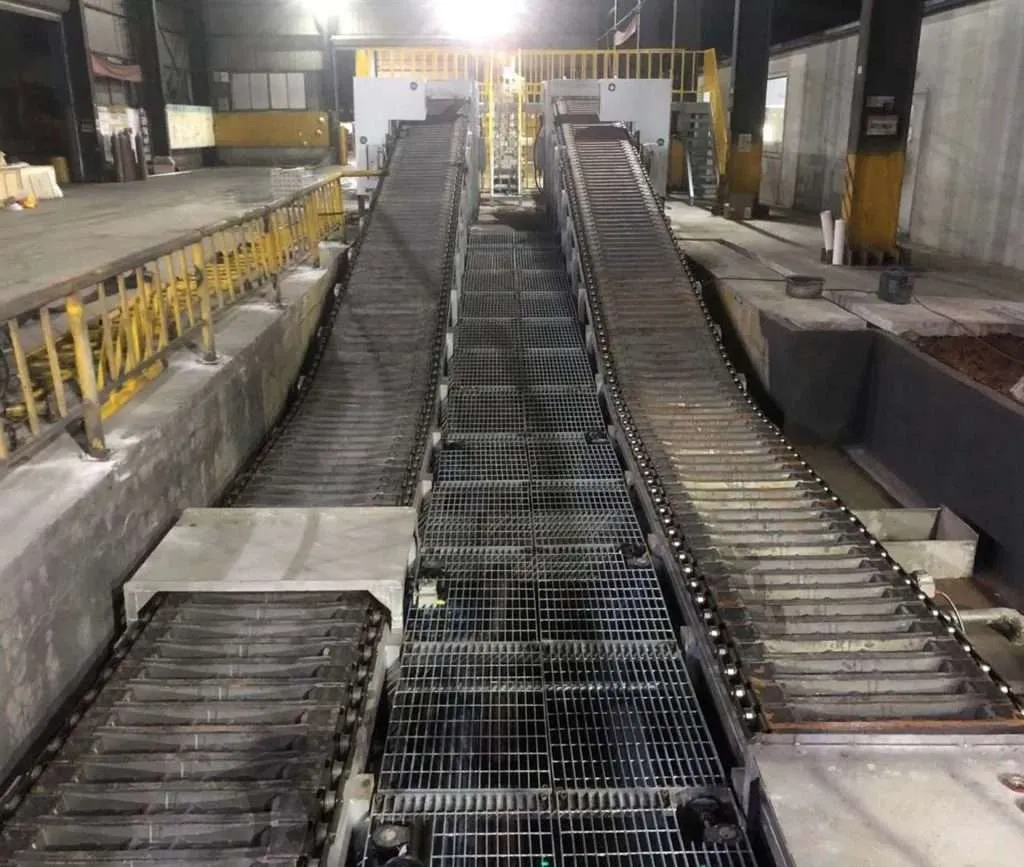

Aluminum Ingot Casting Machine For Casting Aluminium-Lead-Zinc Alloy

Understanding the Efficiency of Aluminum Ingot Casting Machine- Aluminium Ingot Caster in Modern Manufacturing

What is an Aluminum Ingot Casting Machine?

An aluminum ingot casting machine is a specialized piece of equipment designed to cast molten aluminum into ingots or billets of desired shapes and sizes. These machines are an essential component of the aluminum production process, ensuring consistent quality and efficiency.

The casting process involves pouring molten aluminum into refractory-lined molds, which are then cooled to solidify the metal. The resulting ingots or billets can be further processed into various aluminum products, such as sheets, extrusions, or castings.

Key Features of Aluminum Ingot Casting Machines

1.Precision Mold Design: Aluminum ingot casting machines feature precisely engineered molds to ensure accurate dimensions and consistent quality of the cast ingots. The molds are typically made from refractory materials that can withstand the high temperatures of molten aluminum.

2.Temperature Control: Precise temperature control is crucial in the aluminum casting process. These machines are equipped with advanced temperature monitoring and control systems to maintain the optimal temperature range for molten aluminum, ensuring consistent flow and solidification.

3.Automated Operation: Modern aluminum ingot casting machines are highly automated, reducing the need for manual intervention and increasing production efficiency. Automated systems control the pouring, cooling, and ejection processes, ensuring consistent quality and minimizing human error.

Energy Efficiency: Energy efficiency is a key consideration in the design of these machines. Advanced insulation techniques and optimized cooling systems help minimize energy consumption, reducing operational costs and environmental impact.

4.Safety Features: Aluminum ingot casting machines incorporate various safety features, such as enclosed casting areas, emergency stop systems, and proper ventilation, to protect operators and ensure a safe working environment.

Benefits of Modern Aluminum Ingot Casting Machines:

- Efficiency and Productivity: Contemporary casting machines are designed to maximize output while minimizing waste, thanks to their automated and streamlined processes.

- Quality and Uniformity: The precise control over the casting conditions ensures that each ingot meets stringent quality standards with consistent weight and dimensions.

- Energy Conservation: With a focus on sustainability, newer models are geared towards low-energy consumption, reducing the carbon footprint of aluminum manufacturing.

- Versatility: Advanced machines cater to different ingot sizes and alloys, providing flexibility for manufacturers to meet diverse market demands.

Advancements in Aluminum Ingot Casting Technologies:

Manufacturers are continually seeking to improve the aluminum ingot casting process. Innovations such as direct chill (DC) casting, electromagnetic casting, and low-head composite casting are some advancements that have led to improved safety, quality control, and energy efficiency. Additionally, the integration of Internet of Things (IoT) technologies facilitates real-time monitoring and data analysis for predictive maintenance and optimization of the casting process.

Choosing the Right Aluminum Ingot Casting Machine:

When selecting an aluminum ingot casting machine, there are several considerations to keep in mind:

- Production Capacity: Match the machine’s capacity with the intended scale of production to ensure a viable return on investment.

- Quality Compliance: Ensure the machine can produce ingots that conform to international quality standards required for your products.

- Flexibility and Upgradability: Opt for machines that can adapt to potential changes in production demand or technology updates.

- Supplier Reliability: Choose a manufacturer with a strong reputation for quality, customer service, and after-sales support.

Conclusion:

Aluminum ingot casting machines are vital components in the modern manufacturing landscape. Investing in a high-quality casting machine is crucial for businesses looking to excel in the competitive industry of aluminum production. With cutting-edge technology and meticulous design, aluminum ingot casting machines offer a combination of efficiency, quality, and environmental consideration that align with the market’s future. By understanding the importance of these machines, businesses are positioned to make informed decisions that will shape their manufacturing success and sustainability.